Composite frp bar preparation equipment

A composite type and equipment technology, applied in the field of composite FRP bar preparation equipment for civil engineering, can solve the problems of affecting the production process, lack of FRP bar control technology, large changes in mechanical properties and surface morphology of FRP bars, etc., to avoid pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions of the present invention will be described in further detail below through specific implementation methods.

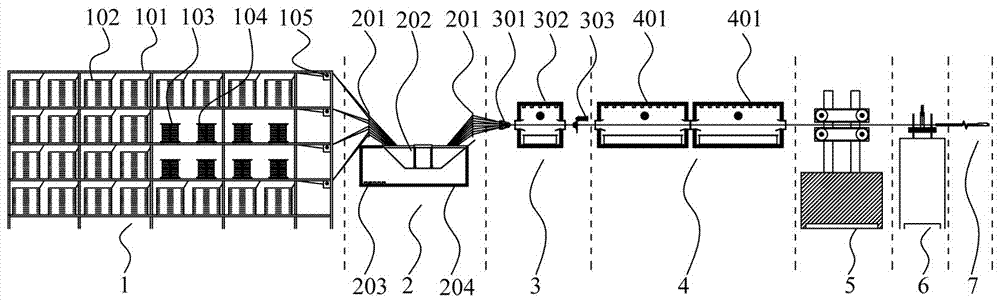

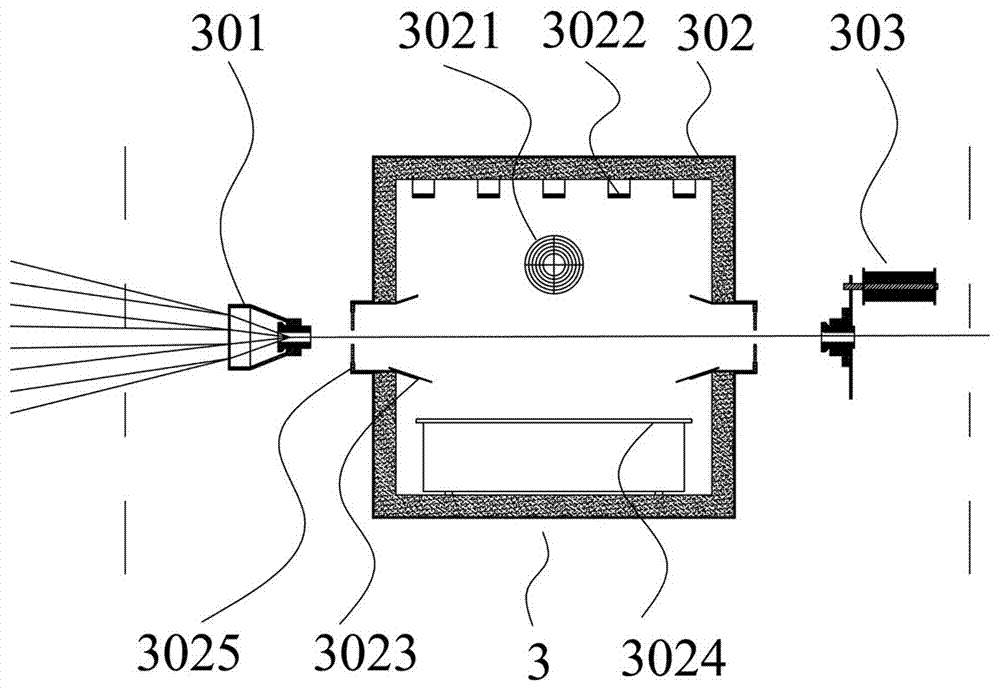

[0024] Examples such as Figure 1~5 As shown, the composite FRP tendon preparation equipment includes a yarn feeding device 1, a dipping device 2, a forming device 3, a heating and curing device 4, a traction device 5, a cutting device 6 and a length control device 7;

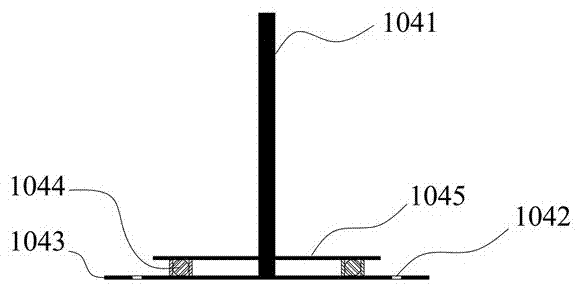

[0025]The yarn feeding device 1 comprises a creel 101, a yarn roller 102 arranged on the creel, a plurality of pressing rollers 105 arranged at the end of the creel, and a roller for placing a steel wire coil 103 arranged on the creel. The shaft mechanism 104, the roller mechanism 104 includes a chassis 1043 detachably fixed on the creel, a central shaft 1041 fixed on the chassis 1043, a rotating tray 1045 passing through the central shaft 1041, and a rotating tray 1045 located between the chassis 1043 and the rotating tray 1045. Thrust bearing 1044 between them, in the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com