Tensile property sample preparation device of ultra-high modulus carbon fiber multifilament and sample preparation method

A technology of tensile performance and carbon fiber, which is applied in the field of ultra-high modulus carbon fiber multifilament tensile performance sample preparation device and sample preparation, can solve the problems of fiber damage, large dispersion, and low tensile strength test value, and achieve Avoid fiber damage, improve accuracy, and ensure consistent results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The embodiment of the present invention also provides a method for preparing a sample of ultra-high modulus carbon fiber multifilament tensile properties, using a pre-wound ultra-high modulus carbon fiber multifilament Glue solution is automatically added dropwise, then the dipped carbon fiber multifilament is cured in an oven, and the reinforcing sheet is pasted for tensile testing. Specifically include the following steps:

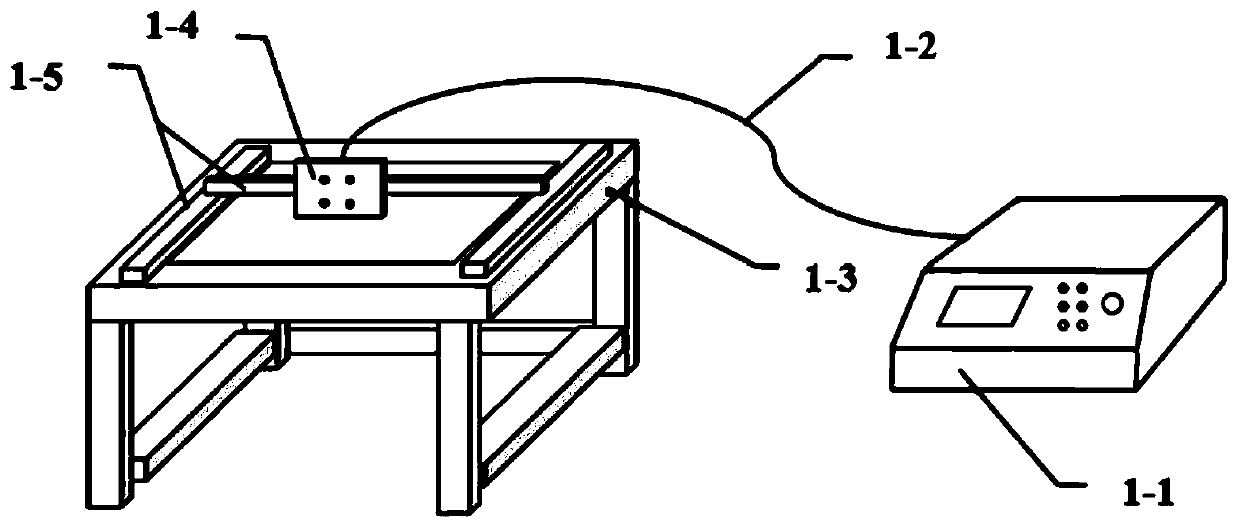

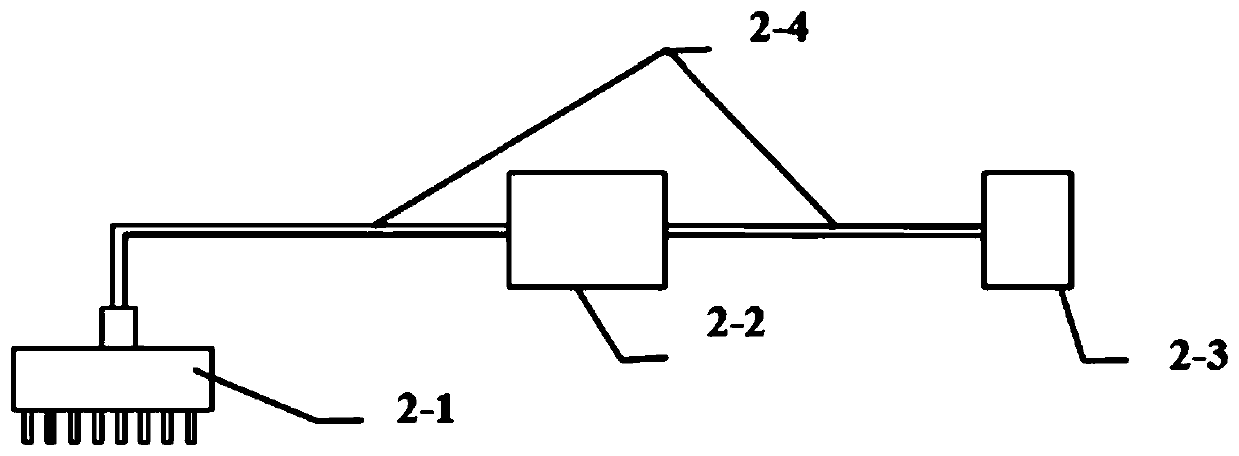

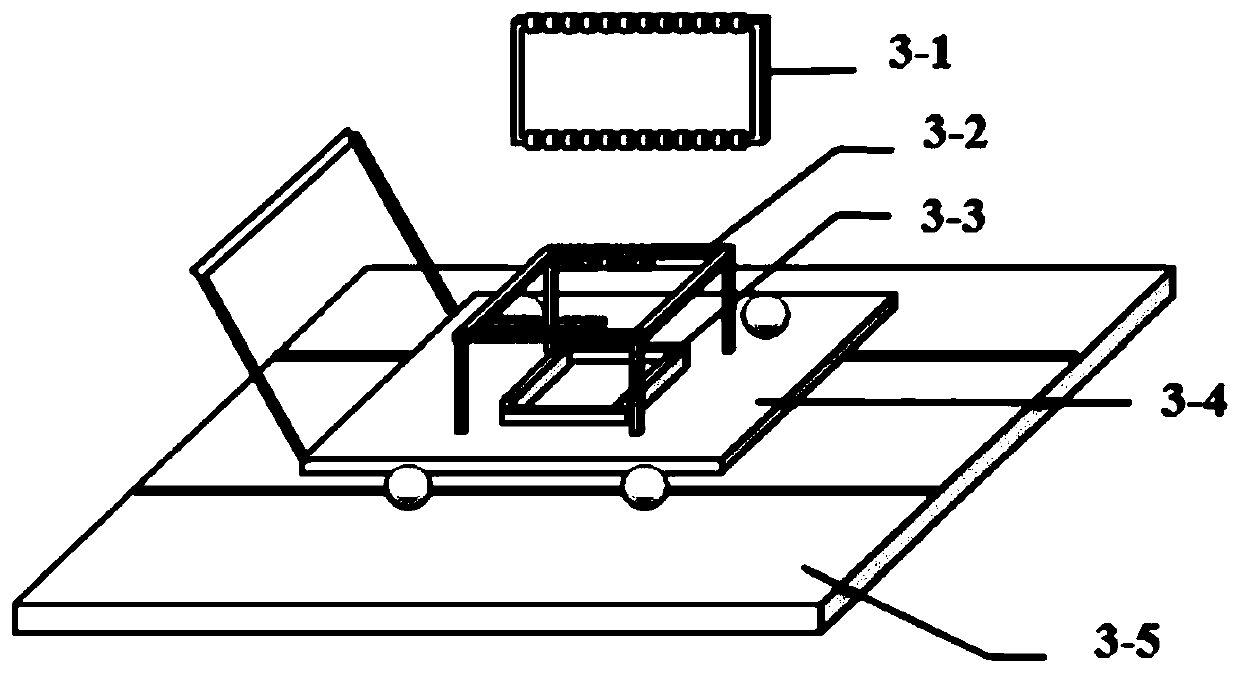

[0044] Step 1. Wind and fix the ultra-high modulus carbon fiber on the fiber positioning frame 3-1 in the auxiliary positioning system, hang it into the fiber hanger 3-2, and place it in the glue recovery tank 3- on the sample delivery car 3-4 3, move to the position directly below the triaxial support frame 1-3 through the ground rail 3-5. Press each axial movement button on the controller 1-1 in the precise control system to adjust the glue dispensing head 2-1 in the automatic dispensing system to the fiber on the fiber frame hanger 1-2 in the ...

Embodiment 1

[0053] Wrap and fix the M55J polyacrylonitrile-based carbon fiber multifilament of Japan Toray Co., Ltd. on the fiber positioning frame 3-1, hang it into the fiber hanger 3-2, and place it in the glue recovery tank 3-3 on the sample delivery car 3-4 The upper position is moved to just below the triaxial support frame 1-3 through the ground rail 3-5. Press each axial movement button on the controller 1-1 in the precision control system, and adjust the dispensing head 2-1 to the fiber positioning winding frame 3-1 on the fiber frame hanger 3-2, so that the dispensing The rightmost end of the glue head 2-1 corresponds to the first groove of the fiber positioning winding frame 3-1; start the operation button of the peristaltic pump 2-2, adjust the flow rate to 100ml / min, and make the dipping solution (100 parts by mass four shrink Glyceryl diaminodiphenylmethane, 80 parts by mass of Nadic anhydride and 2 parts by mass of 2,4,6-three (dimethylaminomethyl) phenol, 150 parts of aceto...

Embodiment 2

[0055] Wrap and fix the M60J polyacrylonitrile-based carbon fiber multifilament of Japan Toray Co., Ltd. on the fiber positioning frame 3-1, hang it into the fiber hanger 3-2, and place it in the glue recovery tank 3-3 on the sample delivery car 3-4 The upper position is moved to just below the triaxial support frame 1-3 through the ground rail 3-5. Press each axial movement button on the controller 1-1 in the precision control system, and adjust the dispensing head 2-1 to the fiber positioning winding frame 3-1 on the fiber frame hanger 3-2, so that the dispensing The rightmost end of the glue head 2-1 corresponds to the first groove of the fiber positioning winding frame 3-1; start the operation button of the peristaltic pump 2-2, adjust the flow rate to 100ml / min, and make the dipping solution (100 parts by mass three shrink Glyceryl triisocyanate, 70 parts by mass of dodecenyl succinic anhydride and 2 parts by mass of benzyldimethylamine and 100 parts of acetone) flow into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com