Sample preparation method for testing mechanical property of carbon fiber

A carbon fiber and performance technology, which is applied in the field of sample preparation for carbon fiber mechanical performance testing, can solve problems such as the inability to guarantee the glue content of the carbon fiber to be tested and affect the mechanical performance of the fiber, and achieve uniform concentration of dipping solution, smooth surface, and uniform dipping Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

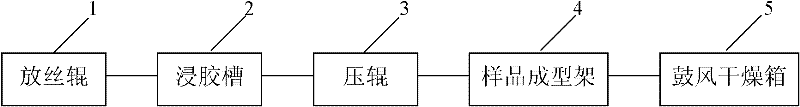

[0027] exist figure 1 Among them, the arrangement of equipment in the technological process of the present invention is: wire-feeding roller 1-dipping tank 2-pressure roller 3-sample forming frame 4-blast drying oven 5.

[0028] The specific process is as follows:

[0029] 1) Put the carbon fiber to be tested on the vertical pay-off roller 1 at a uniform speed. Compared with the previous horizontal laying structure, the pay-off roll 1 is a vertical structure, which can reduce the swing of the wire; can reduce the swing of the wire , the spinning tension is more uniform;

[0030] 2) Pass the carbon fiber passing through the feeding roller 1 through the dipping tank 2. The dipping time is 3 to 10 minutes; the dipping tank 2 is a structure with a movable cover that can be easily removed. The length of the dipping tank 2 is 20 to 40 cm. The best is 30cm; the dipping tank can completely soak the carbon fiber when it passes through the dipping tank, and the dipping amount is basic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com