Fiber spreading device

A technology of fiber and rubber dipping roller, which is applied to the processing of textile materials, equipment configuration, textiles and papermaking, and textile processing machine accessories. It can solve the problems of fiber product performance degradation, uneven fiber width, and reduced production efficiency. Uniform, stable glue content, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below in conjunction with accompanying drawing;

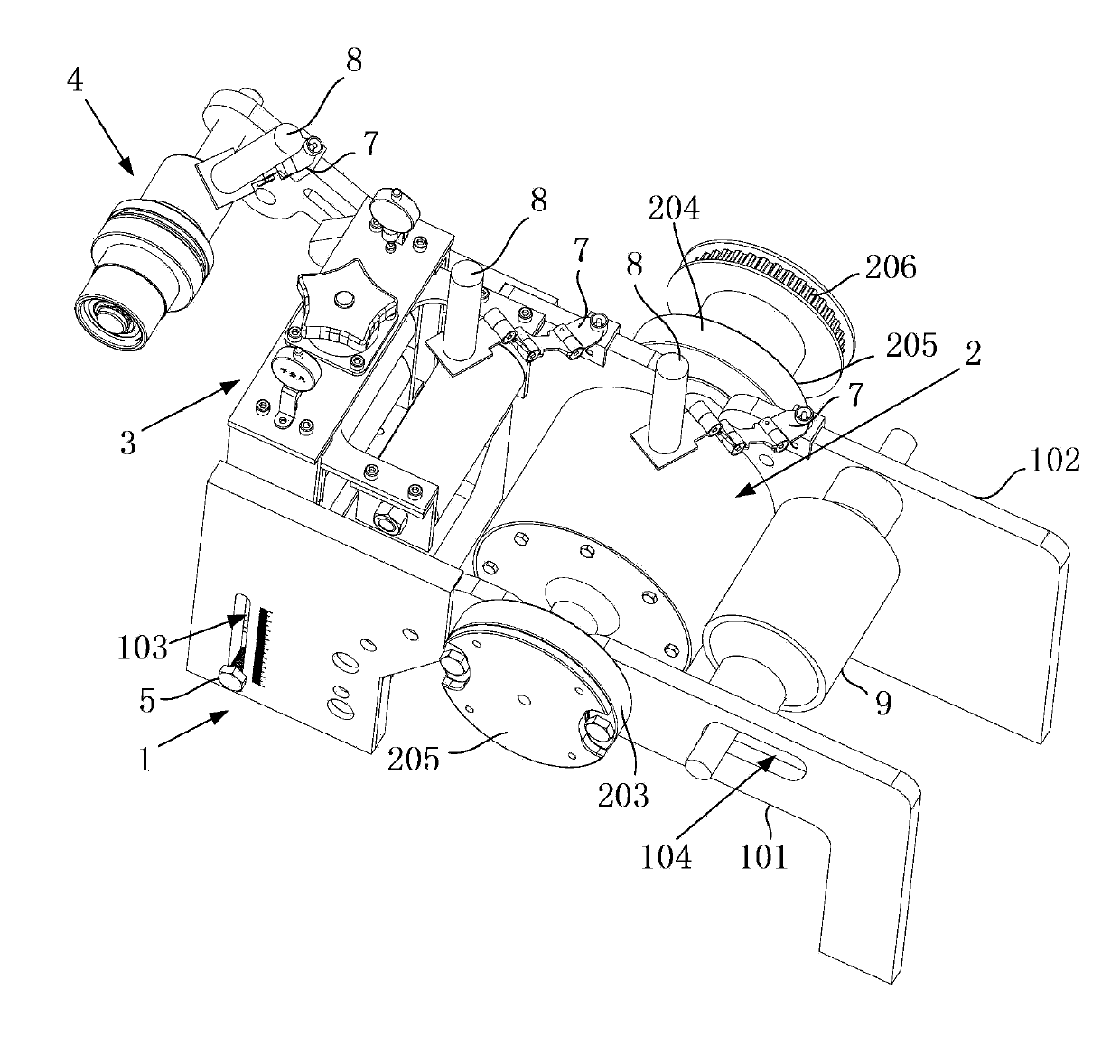

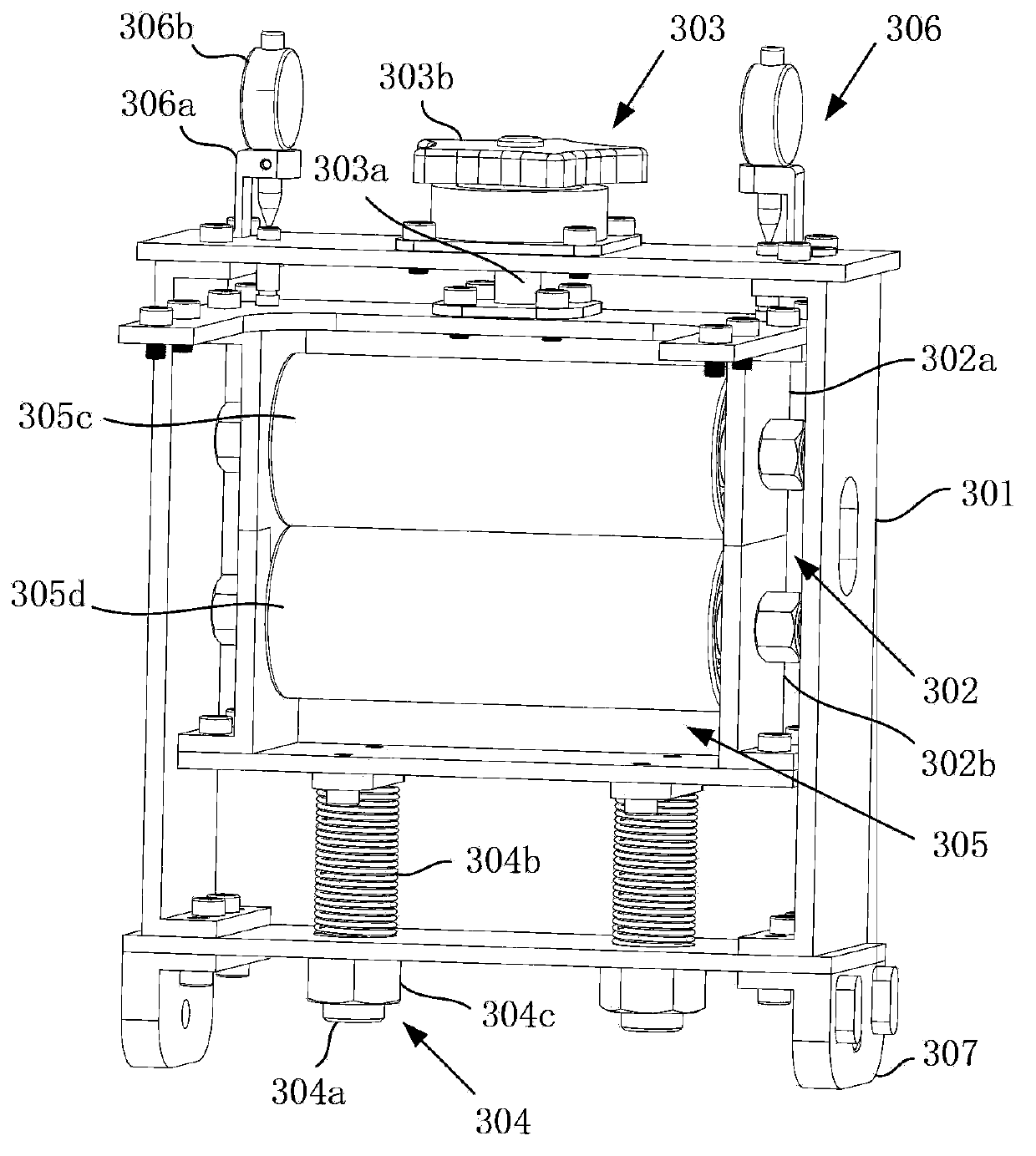

[0034] Fiber spreading device of the present invention, such as figure 1 As shown, it includes frame 1, active rubber dipping roller 2, extrusion device 3, and yarn leveling mechanism 4;

[0035] Wherein, the frame 1 is composed of a side plate A101 and a side plate B102, the side plate A101 and the side plate B102 are arranged vertically and parallel to each other, and an active rubber dipping roller 2 and a glue extruding device 3 are installed between them;

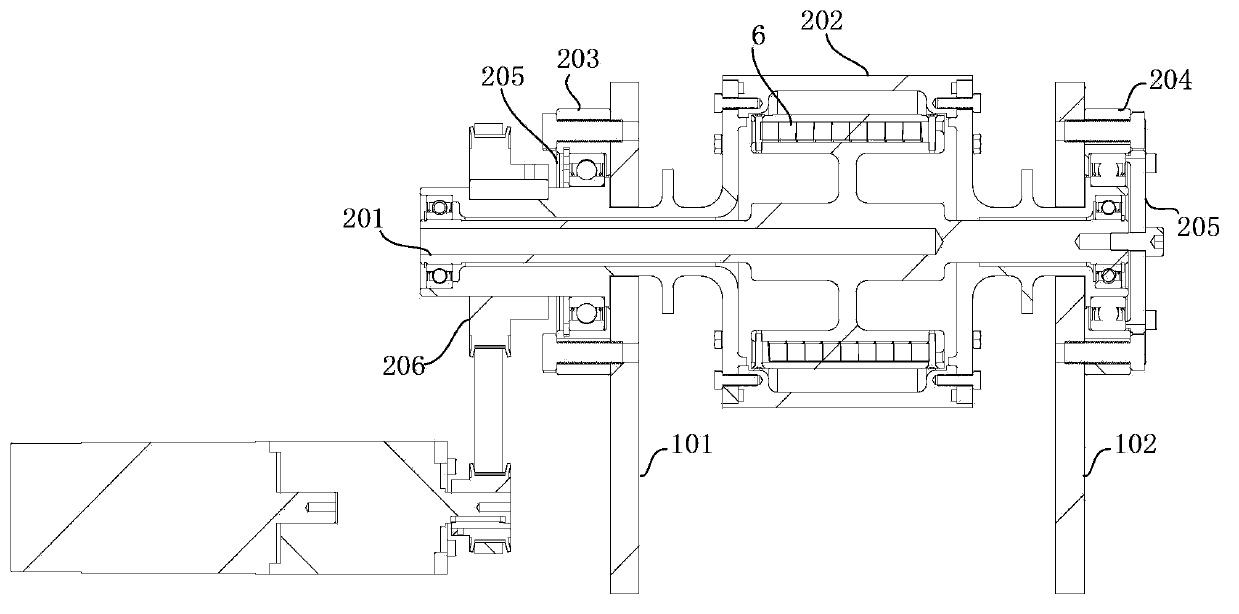

[0036] The active dipping roller 2 is located at the front of the frame 1 and includes a dipping roller fixed shaft 201 and a dipping roller wheel 202; the dipping roller wheel 202 is coaxially socketed on the dipping roller fixed shaft 201 through a bearing, Such as figure 2 As shown; where, after the two ends of the rubber dipping roller 202 pass through the side plate A101 and the side plate B102 respectivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com