Dry winding based production process for carbon fiber arrow shaft

A dry winding, carbon fiber technology, used in other household appliances, household appliances, household components, etc., can solve the problems of poor deflection, increased grinding volume, and increased proportion of defective products, etc., to shorten processing time, improve work efficiency, The effect of long immersion time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Dry winding to manufacture carbon fiber arrow shafts, specifically:

[0033] a. Expand and flatten the 12K carbon fiber in the gluing equipment, and then the gluing equipment releases a certain amount of epoxy resin to the carbon fiber evenly at a set speed, and rolls it while gluing. The weight ratio of epoxy resin to carbon fiber is 30:70. The temperature in the gluing equipment is 50-75°C, and the epoxy resin is a one-component hot-melt epoxy resin.

[0034] b. Sealed and packaged and frozen in the warehouse, the temperature of the warehouse is -2°C.

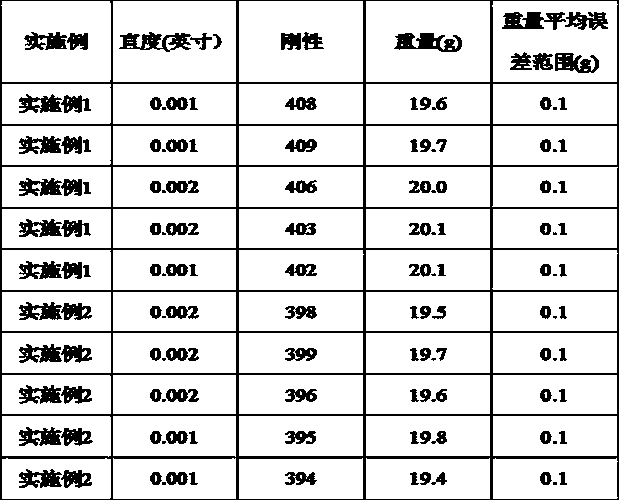

[0035] c. Place the sealed carbon fiber roll with glue at room temperature for 8-16 hours to thaw, then open the vacuum package and place it directly on the processing equipment to wind and process it into an arrow shaft. The processing method is the same as wet processing. 100 arrow shafts with a length of 82 cm were processed, and then straightness, rigidity and weight were tested.

Embodiment 2

[0037] Dry winding to manufacture carbon fiber arrow shafts, specifically:

[0038] a. The carbon fiber of carbon fiber 12K is punched, expanded and flattened in the gluing equipment, and then the gluing equipment releases a certain amount of epoxy resin to the carbon fiber evenly at the set speed, and the gluing is rolled while the glue is applied. The weight ratio of epoxy resin to carbon fiber is 40:60. The temperature in the gluing equipment is 50-75°C, and the epoxy resin is a one-component hot-melt resin.

[0039] b. Sealed and packaged and frozen in the warehouse, the temperature of the warehouse is -8°C.

[0040] c. Place the sealed carbon fiber roll with glue at room temperature for 8-16 hours to thaw, then open the vacuum package and place it directly on the processing equipment to wind and process it into an arrow shaft. The processing method is the same as wet processing. 100 arrow shafts with a length of 82 cm were processed, and then straightness, rigidity and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com