Hollow reactor coil curing device

An air-core reactor and curing device technology, applied in the direction of inductors, coil manufacturing, fixed inductors, etc., can solve the problems of shortening the service life of the reactor, loss of the amount of glue in the coil, and reduction of the insulation level and mechanical properties of the reactor coil.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The content of the present invention will be described below in conjunction with specific embodiments.

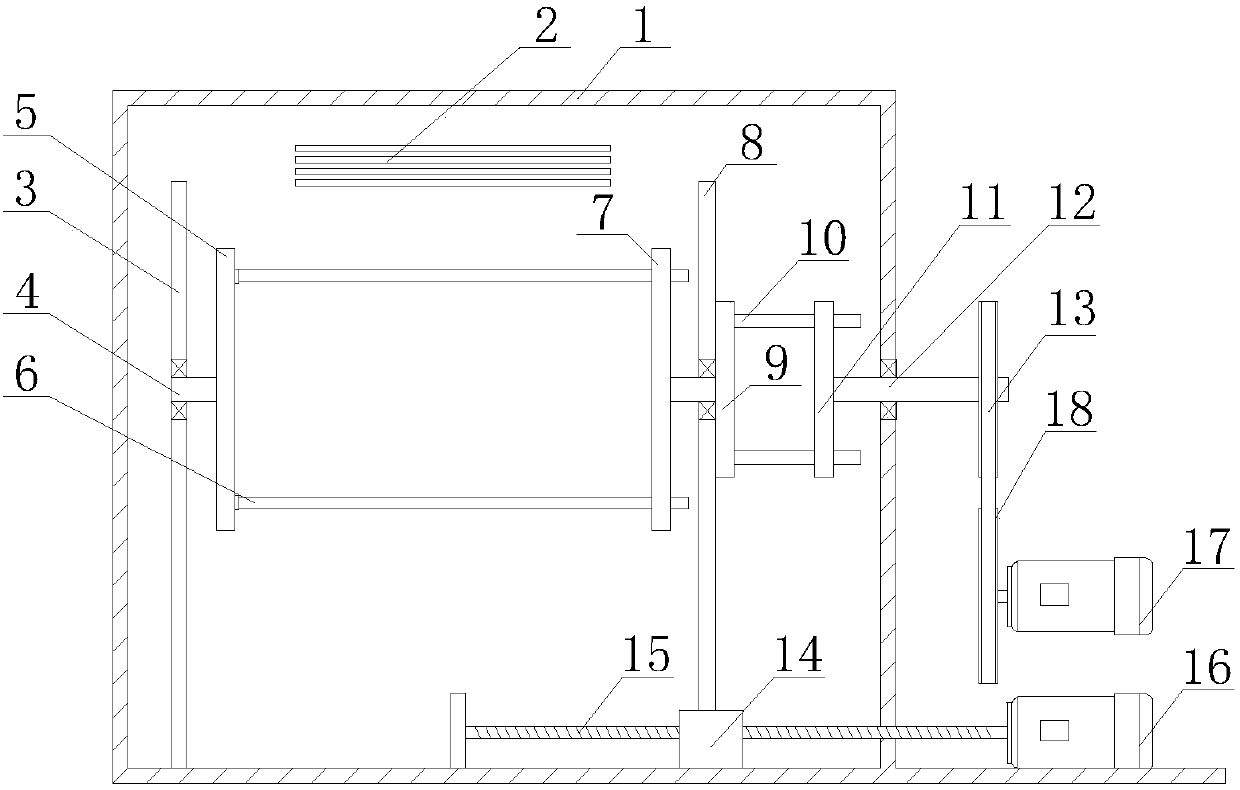

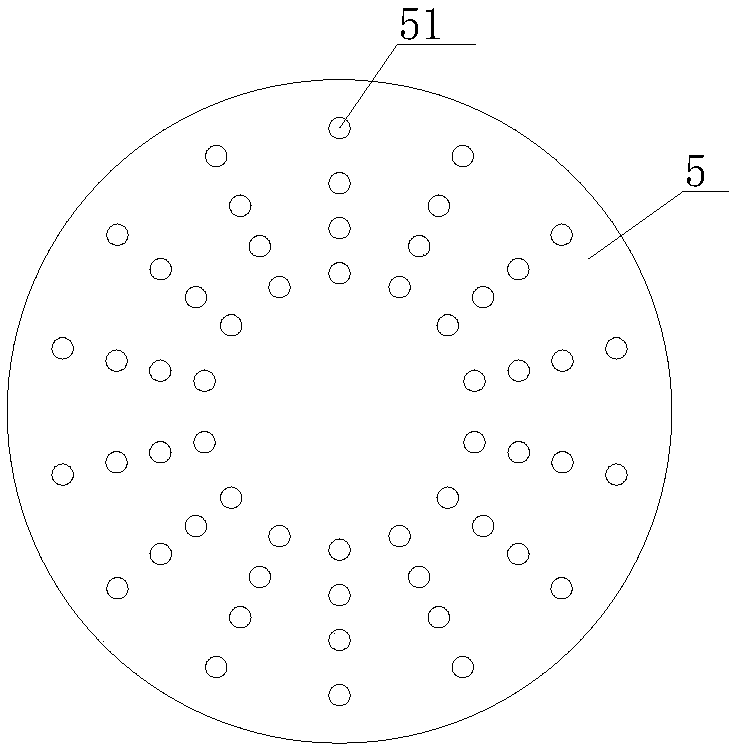

[0014] Such as Figure 1~2 as shown, figure 1 It is a structural schematic diagram of an air-core reactor coil curing device proposed by the present invention; figure 2 It is a structural schematic diagram of the first insulating disk or the second insulating disk in the present invention.

[0015] refer to figure 1 , a kind of air-core reactor coil curing device proposed by the present invention includes a curing chamber 1, a heating tube 2 is arranged in the curing chamber 1, a first vertical plate 3 and a second vertical plate are also arranged in the curing chamber 1 8. The first vertical plate 3 is fixedly installed in the curing chamber 1, and the first vertical plate 3 is rotatably connected with a first insulating disk 5 through the first rotating shaft 4, and the first insulating disk 5 is mounted with A plurality of support rods 6 arranged in a ring sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com