Novel process flow for carrying out surface treatment on carbon fiber

A surface treatment and process technology, applied in fiber treatment, carbon fiber, fabric surface trimming, etc., can solve problems such as unsatisfactory mechanical properties, high energy consumption, and carbon fiber is easy to fluff, so as to achieve easy control of oil content and glue content. The effect of uniform and improved mechanical performance index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

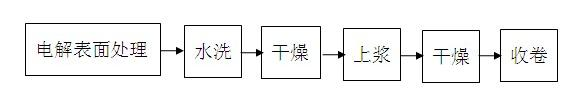

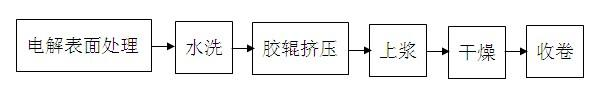

[0022] Such as figure 2 As shown in the schematic diagram of a new carbon fiber surface treatment process, the steps of the surface treatment of carbon fibers adopted in the present invention are electrolytic surface treatment-washing-rubber roller extrusion-sizing-drying-winding.

[0023] When the present invention starts to work, firstly, the carbon fiber surface is treated by electrolytic surface treatment; then, the treated carbon fiber is subjected to a sizing process to form a carbon fiber bundle; then, the sized carbon fiber bundle is dried. , so that it can be shaped; finally, the dried carbon fiber is wound into a bobbin shape by a winding machine, and after winding treatment, it can be sold in the market after being packaged.

[0024] The beneficial effect of the present invention is that, compared with the traditional carbon fiber surface treatment method, the method has uniform moisture content of the carbon fiber tow, obviously reduces the appearance of carbo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com