Production process of novel clear chicken soup

A production process and technology of chicken soup, which is applied in the field of new-type clear chicken soup production process, can solve the problems of discounted nourishing nutritional effect, difficult control of oil content, unstable taste, etc., to achieve guaranteed nourishing nutritional effect, easy control of oil content, good taste stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

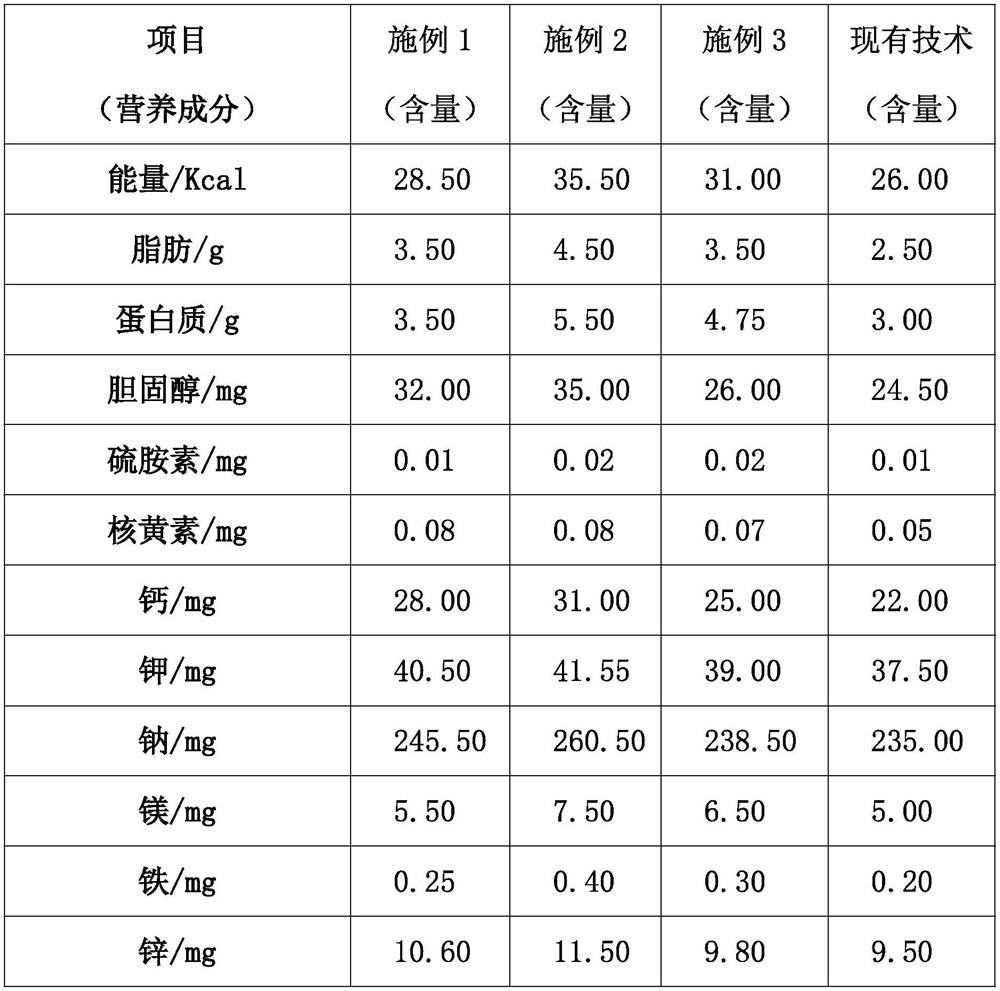

Examples

Embodiment 1

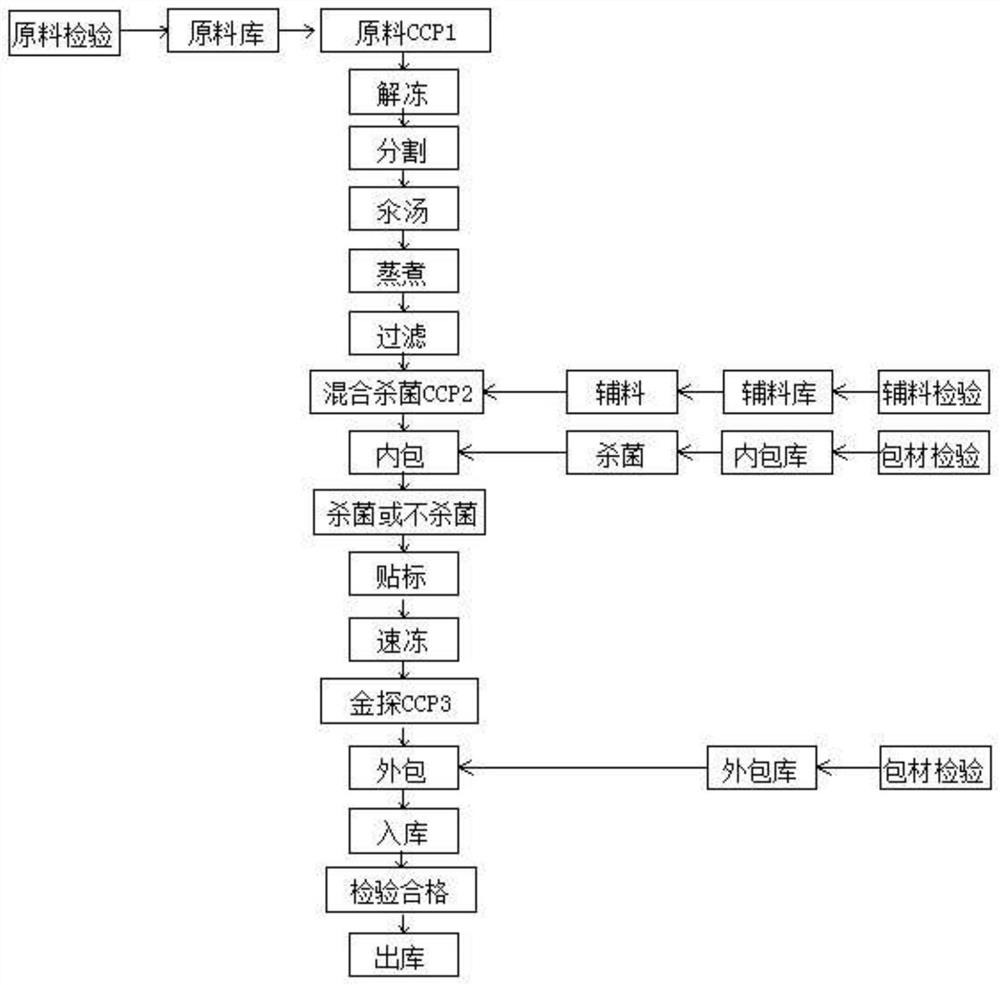

[0032] refer to figure 1 , Propose a kind of production technology of novel clear chicken soup in the present embodiment, comprise.

[0033] In this embodiment, the following steps are included: raw material inspection→raw material storage→raw material CCP1→thawing→segmentation→boiling soup→cooking→filtering→mixing and sterilizing CCP2→inner packaging→sterilization or non-sterilization→labeling→quick freezing→metal detector CCP3→outsourcing →Storage→Qualified inspection→Exit;

[0034] In the raw material CCP1 step, the main raw material is old hen, in order to ensure the food safety control point, specifically select old hen fed with pollution-free natural food;

[0035] In the thawing step, the thawing time is 0.5-1.5h, and the thawing is carried out in warm water at 45-55°C to a natural state;

[0036] In the dividing step, the thawed old hen is cut into dispersed chicken nuggets by a crusher;

[0037] In the step of boiled soup, first scald the cut chicken pieces with bo...

Embodiment 2

[0051] The differences between this example and Example 1 are as follows:

[0052] In this example, in the dividing step, the thawed old hen is cut into chicken nuggets with a size of 10 cm by a crusher.

[0053] In this example, in the step of boiling the soup, the seasoning in the fresh seasoning soup includes the following percentages of the total raw materials: 0.4% sesame oil, 0.25% salt, 0.25% monosodium glutamate, 0.45% cooking wine, and 0.55% cornstarch.

[0054] In this example, in the step of boiled soup, the seasoning soup is prepared in advance, and the seasoning soup that has been seasoned and boiled is poured into the chicken nuggets in the container and boiled; then Stir and marinate for 55 minutes until tasty.

[0055] In this example, in the cooking step, add water to the chicken nuggets marinated in boiled soup and cook them on high heat for 0.75 hours, then cook them on medium fire for 1.75 hours, and finally cook them on a small fire for 3.5 hours. Cook o...

Embodiment 3

[0058] The differences between this example and Example 1 are as follows:

[0059] In this example, in the dividing step, the thawed old hen is cut into chicken nuggets with a size of 13 cm by a crusher.

[0060] In this example, in the step of boiling the soup, the seasoning in the fresh seasoning soup includes the following percentages of the total raw materials: 0.5% sesame oil, 0.3% salt, 0.2% monosodium glutamate, 0.35% cooking wine, and 0.7% cornstarch.

[0061] In this example, in the step of boiled soup, the seasoning soup is prepared in advance, and the seasoning soup that has been seasoned and boiled is poured into the chicken nuggets in the container and boiled; then Stir and marinate for 60 minutes until tasty.

[0062] In this example, in the steaming step, add water to the chicken nuggets marinated in the boiled soup and cook them on a high heat for 1 hour, then cook them on a medium fire for 2 hours, and cook them on a low fire for the last 3 hours. until the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com