Aerogel thermal insulation material and preparation method thereof

A technology of air condensation and temperature control, which is applied in the direction of pretreatment surface, coating, and liquid coating device on the surface, etc. It can solve the problems of affecting the thermal insulation effect, complex processing technology, thermal insulation material performance needs to be improved, etc., and achieve the processing technology Smooth, uniform glue content, easy processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

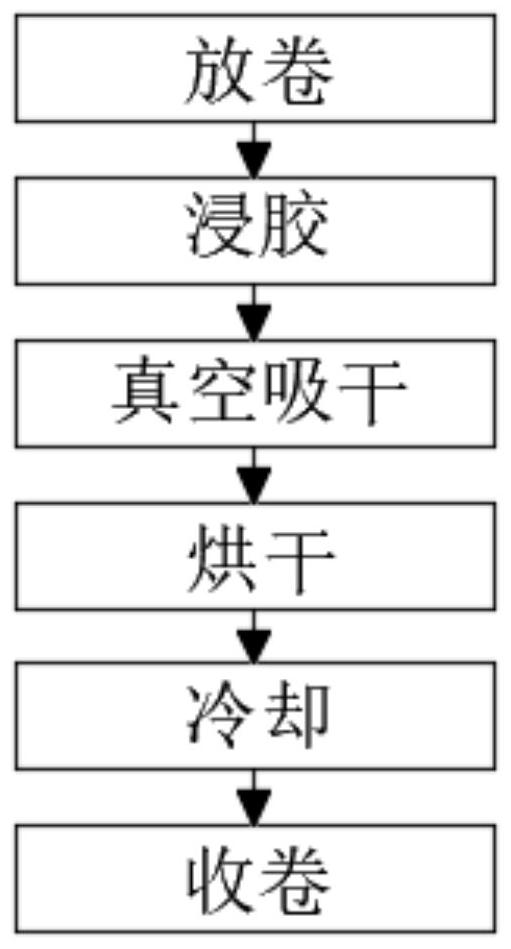

[0027] A preparation method of an air-condensed thermal insulation material, comprising the following steps:

[0028] 1) Unwinding: Unwind the non-woven fabric through an unwinding machine to remove surface dust;

[0029] The fiber forming the non-woven fabric is one of polyester fiber, polypropylene fiber and polyacrylonitrile fiber;

[0030] 2) Dipping: inject glue into the dipping pool of the dipping machine, the temperature of the glue is controlled at 32°C, and the unfolded non-woven fabric is sent into the dipping machine, and the glue penetrates into the non-woven fabric;

[0031] The glue is made by mixing enzymes, surfactants, organic acids, silanol and water;

[0032] The excess trace glue in the process of dipping and vacuum drying is recovered through the pipeline and then sent to the dipping tank;

[0033] The dipping tank is equipped with a flying knife blowing device, and the non-woven fabric after dipping is treated with a flying knife blowing glue;

[0034]...

Embodiment 2

[0043] A preparation method of an air-condensed thermal insulation material, comprising the following steps:

[0044] 1) Unwinding: Unwind the non-woven fabric through an unwinding machine to remove surface dust;

[0045] The fiber forming the non-woven fabric is one of polyester fiber, polypropylene fiber and polyacrylonitrile fiber;

[0046] 2) Dipping: inject glue into the dipping tank of the dipping machine, the temperature of the glue is controlled at 36°C, and the unfolded non-woven fabric is sent into the dipping machine, and the glue penetrates into the non-woven fabric;

[0047] The glue is made by mixing enzymes, surfactants, organic acids, silanol and water;

[0048] The excess trace glue in the process of dipping and vacuum drying is recovered through the pipeline and then sent to the dipping tank;

[0049] The dipping tank is equipped with a flying knife blowing device, and the non-woven fabric after dipping is treated with a flying knife blowing glue;

[0050]...

Embodiment 3

[0058] A preparation method of an air-condensed thermal insulation material, comprising the following steps:

[0059] 1) Unwinding: Unwind the non-woven fabric through an unwinding machine to remove surface dust;

[0060] The fiber forming the non-woven fabric is one of polyester fiber, polypropylene fiber and polyacrylonitrile fiber;

[0061] 2) Glue dipping: inject glue into the dipping pool of the dipping machine, the temperature of the glue is controlled at 40°C, send the unfolded non-woven fabric into the dipping machine, and the glue penetrates into the non-woven fabric;

[0062] The glue is made by mixing enzymes, surfactants, organic acids, silanol and water;

[0063] The excess trace glue in the process of dipping and vacuum drying is recovered through the pipeline and then sent to the dipping tank;

[0064] The dipping tank is equipped with a flying knife blowing device, and the non-woven fabric after dipping is treated with a flying knife blowing glue;

[0065] D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com