Flame-retardant polyarylether-based composition

A polyarylene ether and composition technology is applied in the field of flame-retardant polyarylene ether-based compositions, which can solve the problems of not being able to obtain better guarantees, the overall performance cannot meet the needs of high-frequency and high-speed communication, and the high dosage, and achieves Smooth surface, simple and efficient production method, and uniform glue content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

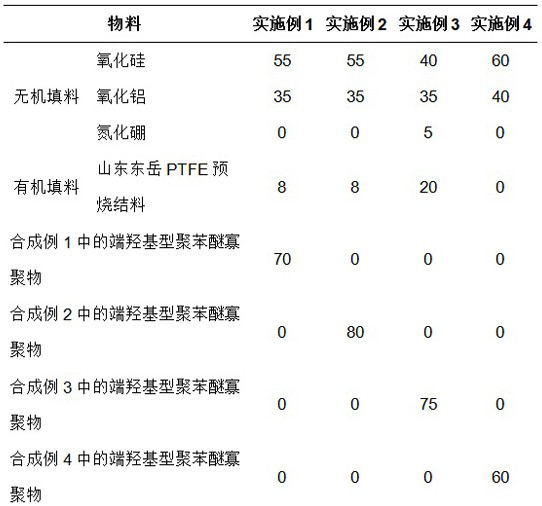

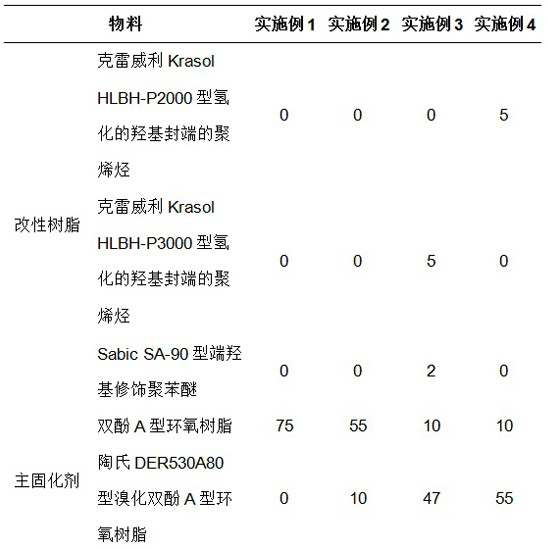

Examples

Synthetic example 1

[0074] Take 450 parts of polyphenylene ether (Mn=23000) and dissolve it in toluene to form a 20wt / v% solution, then add 5 parts of 4,4'-biphenol, 20 parts of 1,1,2,2-tetra(4 -Hydroxyphenyl)ethane, 20 parts of bromide of 10-(2,5-dihydroxyphenyl)-10-hydro-9-oxa-10-phosphaphenanthrene-10-oxide and 55 parts of 9, The bromide of 10-dihydro-9-oxa-10 phosphaphenanthrene-10-oxide and rosebic acid adduct, after fully stirring and mixing, slowly add 50 parts of dibenzoyl peroxide in batches, The reaction was carried out for 8 hours under the condition that the temperature of the system was controlled at 100°C.

[0075] Then, add a small amount of methanol to the system, stir slowly to mix evenly, and let it stand overnight at room temperature, and then filter to remove the high molecular weight polyphenylene ether chains that cannot fully undergo the chain redistribution reaction; then, add a large amount of Methanol was stirred vigorously to fully separate the hydroxyl-terminated poly...

Synthetic example 2

[0077] Take 380 parts of polyphenylene ether (Mn=19000) and dissolve it in toluene to form a 25wt / v% solution, then add 15 parts of tetrabromobisphenol A, 10 parts of 1,1,2,2-tetrakis(4-hydroxy Phenyl)ethane, 15 parts of bromide of 10-(2,5-dihydroxyphenyl)-10-hydro-9-oxa-10-phosphaphenanthrene-10-oxide and 60 parts of 9,10- The bromide of dihydro-9-oxa-10phosphaphenanthrene-10-oxide and rosenic acid adduct, after fully stirring and mixing, slowly add 32 parts of dibenzoyl peroxide in batches, in the control system The reaction was carried out for 24 hours at a temperature of 90°C.

[0078] Then, add a small amount of methanol to the system, stir slowly to mix evenly, and let it stand overnight at room temperature, and then filter to remove the high molecular weight polyphenylene ether chains that cannot fully undergo the chain redistribution reaction; then, add a large amount of Methanol was stirred vigorously to fully separate the hydroxyl-terminated polyphenylene ether olig...

Synthetic example 3

[0080] Take 400 parts of polyphenylene ether (Mn=35000) and dissolve it in toluene to form a 14.5wt / v% solution, then add 6 parts of tetrabromobisphenol A, 4 parts of 1,1,2,2-tetra(4- hydroxyphenyl)ethane, 25 parts of bromide of 10-(2,5-dihydroxyphenyl)-10-hydro-9-oxa-10-phosphaphenanthrene-10-oxide and 65 parts of 9,10 -The bromide of dihydro-9-oxa-10 phosphaphenanthrene-10-oxide and rosenic acid adduct, after fully stirring and mixing, slowly add 35 parts of dibenzoyl peroxide step by step, under control The reaction was carried out for 6 hours at a system temperature of 105°C.

[0081] Then, add a small amount of methanol to the system, stir slowly to mix evenly, and let it stand overnight at room temperature, and then filter to remove the high molecular weight polyphenylene ether chains that cannot fully undergo the chain redistribution reaction; then, add a large amount of Methanol was stirred vigorously to fully separate the hydroxyl-terminated polyphenylene ether oligo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com