Production process of high-frequency circuit board glass fiber substrate

A glass fiber substrate, high-frequency circuit technology, applied in circuit substrate materials, printed circuits, printed circuit components, etc., can solve the problem that high-frequency circuit boards cannot be well applied, and copper clad laminates cannot be applied to the use environment and dielectric loss. High problems, to achieve the effect of uniform overall glue content, good wettability and permeability, and avoid leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

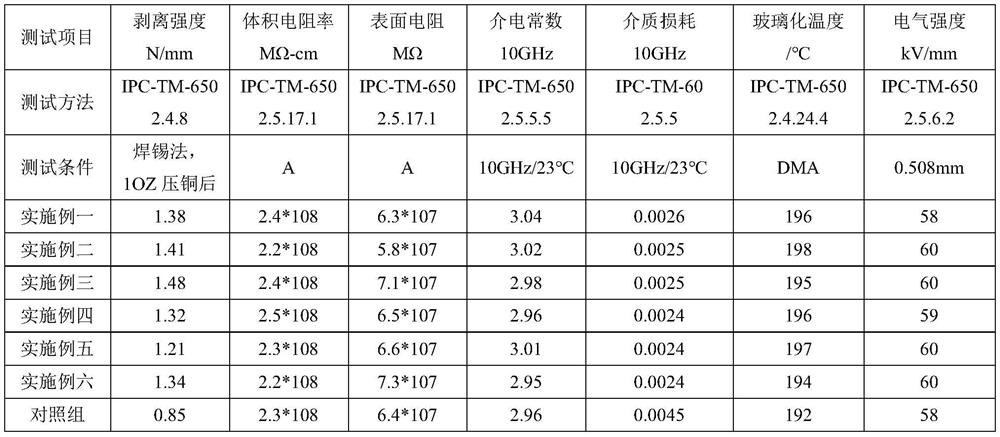

Examples

Embodiment 1

[0041] Embodiment 1. The production process of the high-frequency circuit board glass fiber substrate in this embodiment includes the following steps:

[0042] Prepare dipping solution;

[0043] To make glass fiber bonding cloth, that is to dry the raw material of glass fiber cloth at least twice, and perform several dipping treatments before each drying treatment;

[0044] The glass fiber bonding cloth is cut according to the required shape and size to obtain a prepreg, and the prepreg is covered with copper foil and pressed to make a glass fiber substrate.

[0045] Dipping solution comprises dipping solution A, dipping solution B,

[0046] Dipping solution A comprises the raw material of following parts by weight:

[0047] 80 parts of epoxy modified PPO resin, 15 parts of hydrocarbon resin, 20 parts of modified cyanate resin, 10 parts of diallyl bisphenol A type benzoxazine resin, 5 parts of triallyl isocyanurate 1 part, 2 parts of curing agent, 1 part of initiator, 0.2 p...

Embodiment 2

[0068] Embodiment 2. The production process of the high-frequency circuit board glass fiber substrate in this embodiment includes the following steps:

[0069] Prepare dipping solution;

[0070] To make glass fiber bonding cloth, that is to dry the raw material of glass fiber cloth at least twice, and perform several dipping treatments before each drying treatment;

[0071] The glass fiber bonding cloth is cut according to the required shape and size to obtain a prepreg, and the prepreg is covered with copper foil and pressed to make a glass fiber substrate.

[0072] Dipping solution comprises dipping solution A, dipping solution B,

[0073] Dipping solution A comprises the raw material of following parts by weight:

[0074] 120 parts of epoxy modified PPO resin, 15 parts of hydrocarbon resin, 30 parts of modified cyanate resin, 25 parts of diallyl bisphenol A type benzoxazine resin, 15 parts of triallyl isocyanurate Parts, 5 parts of curing agent, 2 parts of initiator, 1.2...

Embodiment 3

[0095] Embodiment 3. The production process of the high-frequency circuit board glass fiber substrate in this embodiment includes the following steps:

[0096] Prepare dipping solution;

[0097] To make glass fiber bonding cloth, that is to dry the raw material of glass fiber cloth at least twice, and perform several dipping treatments before each drying treatment;

[0098] The glass fiber bonding cloth is cut according to the required shape and size to obtain a prepreg, and the prepreg is covered with copper foil and pressed to make a glass fiber substrate.

[0099] Dipping solution comprises dipping solution A, dipping solution B,

[0100] Dipping solution A comprises the raw material of following parts by weight:

[0101] 80 parts of epoxy modified PPO resin, 15 parts of hydrocarbon resin, 30 parts of modified cyanate resin, 15 parts of diallyl bisphenol A type benzoxazine resin, 5 parts of triallyl isocyanurate 2 parts, curing agent 2 parts, initiator 3 parts, accelerat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com