A preparation process of room temperature curing wet prepreg

A technology of curing at room temperature and preparation process, which is applied in chemical instruments and methods, lamination devices, lamination auxiliary operations, etc., and can solve problems such as high labor intensity, low production efficiency, and difficulty in controlling the amount of glue and uniformity. Achieve high production efficiency, save labor costs, and avoid local rich and poor rubber phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

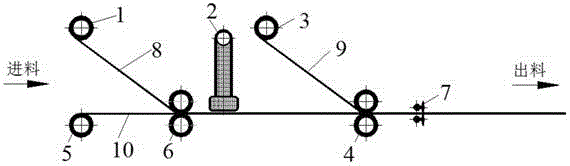

[0024] The preparation technology of a kind of room temperature curing wet prepreg of the present invention is to carry out the production of room temperature curing wet prepreg by adopting prepreg machine, figure 1 A schematic diagram of the prepreg machine is shown. This preparation process comprises the following steps:

[0025] Unwinding step: place the roll of base material 8 on the discharge roller 1, place the roll of the first release film 9 on the first release roll 3, place the roll of the second release film 10 on the second release roll On the roller 5, the traction substrate 8, the first isolation film 9 and the second isolation film 10 move linearly towards the same direction;

[0026] Glue spraying step: use the glue spraying device 2 to spray the colloid on the surface of the substrate 8;

[0027] Coating step: compounding the first isolation film 9 and the second isolation film 10 on both surfaces of the substrate 8 by extrusion of the first extrusion roller...

Embodiment 1

[0038] Using a room temperature curing epoxy adhesive as the colloid and 0.2mm thick glass fiber cloth as the substrate 8, prepare 30 layers of rectangular glass steel plates with a size of 8m×1.3m. The actual work results found that using the traditional hand lay-up process, it takes 360 minutes for two workers to mix glue, hand lay-up layer by layer, and rush to complete 30 layers of laying. Using this preparation process, the time required for two workers is 120 minutes, and the work efficiency is increased to 3 times; comparing the prepregs produced by the two processes, the color of the prepreg produced by this preparation process is more uniform, indicating that the glue content is uniform It is difficult to avoid the phenomenon of rich and poor glue in individual areas on the surface of the material using the hand lay-up method; comparing the uniformity of the thickness and size of the plate after molding, it is found that the thickness and size uniformity of the prepreg...

Embodiment 2

[0040] The glue spraying pressure remains unchanged, the braid transmission speed is reduced from 0.4m / s to 0.3m / s, and the glue content of the prepreg after glue spraying is increased from 27% to 35.5%. Through this preparation process, wet prepregs with different glue contents can be prepared according to production needs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com