Resin tank for digital light processing (DLP) photocuring 3D printer

A 3D printer and resin tank technology, applied in the direction of additive processing, etc., can solve the problems that the printer frame is easily damaged, cannot generate deformation, and affect the molding effect of objects, so as to improve economic efficiency and improve the effect of smoothness.

Active Publication Date: 2016-03-02

NINGBO YINZHOU INTELLIGENT MFG DIGITAL TECH

View PDF5 Cites 13 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Considering the overall rigidity of the current resin tank, the material is generally made of glass or acrylic, and the bottom of the tank cannot produce a certain amount of deformation. The printing platform needs to apply a large external force to lift it up against its own weight and gas and hydraulic pressure. The requirements for the overall structural strength of the printer frame are met, and the printer frame is also easily damaged; at the same time, the printing layer is rigidly separated from the bottom of the resin tank, which will also affect the demoulding effect of the printing layer. To construct an object by printing, each printing layer needs to be demolded from the bottom of the resin tank during the above-mentioned whole process, so the resin tank with the above structure will seriously affect the final molding effect of the object and cannot improve its surface finish

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

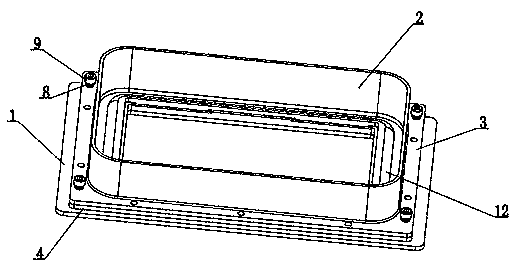

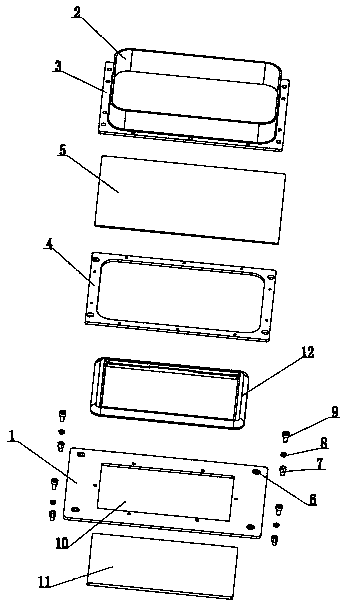

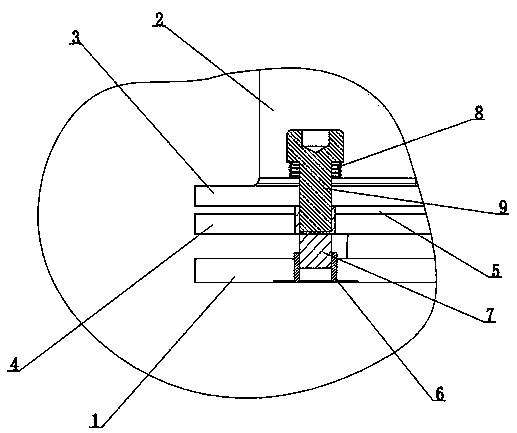

The invention discloses a resin tank for a digital light processing (DLP) photocuring 3D printer. A periphery mounting face is formed at the bottom of a box frame, a soft cushion plate is arranged under the periphery mounting face and fixedly attached to the periphery mounting face, and a fluorinated ethylene propylene copolymer thin film or a teflon thin film is clamped between the periphery mounting face and the cushion plate. The box frame can be lifted relative to a bottom plate through external force and can be reset in time after the external force is gone, an opening is formed in the bottom plate and located in the box frame, and a transparent sealing plate covers the opening and is fixed through a cambered pressing frame. When the box frame is kept in a downward-pressing state through the acting force of spiral springs, part of the cambered pressing frame extends into the box frame, and the fluorinated ethylene propylene copolymer thin film or the teflon thin film is tensioned. The technical purpose that the bottom of the resin tank can be conveniently stripped from cured resin in the working process of the DLP photocuring 3D printer is achieved, and the printing effect is improved.

Description

technical field The invention relates to a component for a DLP light-curing 3D printer, in particular to a resin tank for a DLP light-curing 3D printer. Background technique The working principle of DLP light-curing 3D printers: using digital light processing (DLP) technology, a projector is used to cure liquid photosensitive resin layer by layer. It is capable of printing objects with very fine resolution, surpassing typical fused filament fabrication (FFF) 3D printers. DLP light curing 3D printer mainly consists of two parts: software and hardware. The above hardware part mainly includes the printer frame, projector, printing platform and resin tank. In the specific work, the continuous layer structure of the printing platform sinks into the resin tank. The resin tank is basically a cylinder filled with photosensitive resin. The image signal generated by the software part is projected by the projector after digital processing (DLP). Out, the projected light comes into ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B29C67/00B33Y30/00

Inventor 潘俊深沈杰

Owner NINGBO YINZHOU INTELLIGENT MFG DIGITAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com