Method for preparing composite polymer electret

A composite polymer and electret technology, applied in chemical instruments and methods, layered products, lamination devices, etc., can solve the problems of electret charge attenuation, limited application, etc., to achieve difficult attenuation, good resistance to alcohol cleaning performance, the effect of good surface potential stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

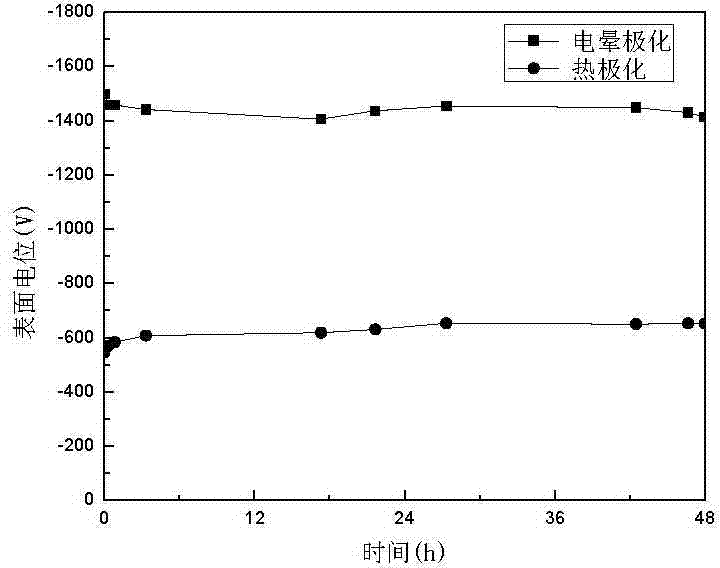

[0038] The preparation method of polytetrafluoroethylene (PTFE) / polyvinylidene fluoride (PVDF) / polytetrafluoroethylene (PTFE) three-layer composite polymer electret comprises the following steps:

[0039] (1) Preparation of composite membrane: Cover a layer of PVDF powder layer with a thickness of 25 μm on a PTFE membrane with a thickness of 50 μm, and then cover a layer of PTFE membrane with a thickness of 50 μm on the PVDF powder layer, and then use a flat vulcanizer After being pressed at a temperature of 180°C and a pressure of 25MPa for 5 minutes, cool to room temperature to make them stick together;

[0040] (2) Formation of electret: injecting the composite film prepared in step (1) by means of corona polarization or thermal polarization;

[0041] Wherein, the corona polarization injector condition is: under the condition of keeping the temperature at 100°C, charge with a voltage of 10kV for 5min, then keep the voltage constant to lower the temperature to room temperature...

Embodiment 2

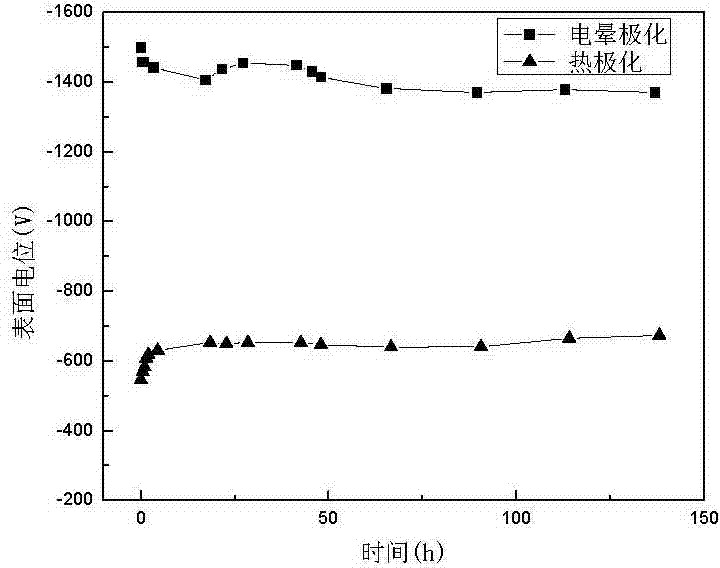

[0045] The preparation method of fluorinated ethylene propylene copolymer (FEP) / polyvinylidene fluoride (PVDF) / fluorinated ethylene propylene copolymer (FEP) three-layer composite polymer electret comprises the following steps:

[0046] (1) Preparation of composite membrane: Cover a layer of PVDF powder layer with a thickness of 25 μm on the FEP membrane with a thickness of 50 μm, and then cover a layer of FEP membrane with a thickness of 50 μm on the PVDF powder layer, and then use a flat vulcanizer to After pressing at 180°C and 25MPa pressure for 5 minutes, cool to room temperature to make them stick together;

[0047] (2) Formation of electret: injecting the composite film prepared in step (1) by means of corona polarization or thermal polarization;

[0048] Wherein, the corona polarization injector condition is: under the condition of keeping the temperature at 100°C, charge with a voltage of 10kV for 5min, then keep the voltage constant to lower the temperature to room t...

Embodiment 3

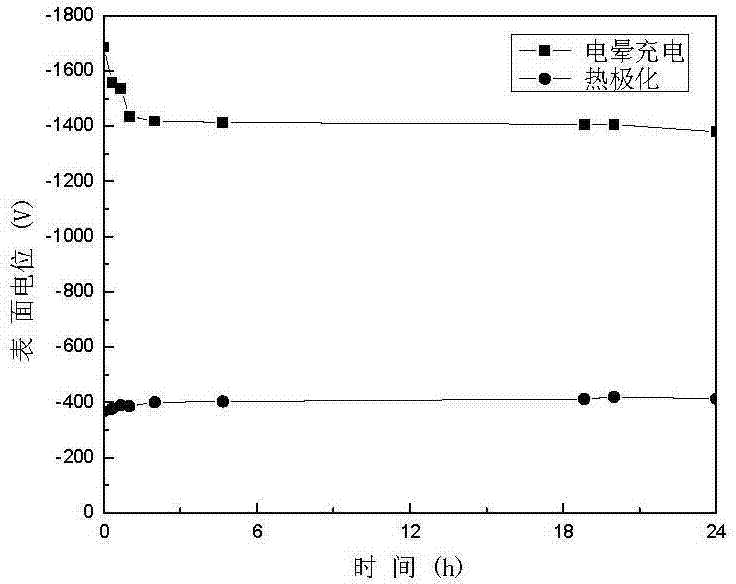

[0052] The preparation method of polytetrafluoroethylene (PTFE) / vinylidene fluoride and trifluoroethylene copolymer (P(VDF-TrFE) / polytetrafluoroethylene (PTFE) three-layer composite polymer electret comprises the following steps:

[0053] (1) Preparation of composite membrane: first cover a layer of P(VDF-TrFE) membrane with a thickness of 10 μm on a PTFE membrane with a thickness of 25 μm, and then cover a layer with a thickness of 25 μm on the P(VDF-TrF)E membrane The PTFE film is then pressed with a flat vulcanizing machine at a temperature of 200 ° C and a pressure of 20 MPa for 5 minutes, and then cooled to room temperature to make it bond together;

[0054] (2) Formation of electret: injecting the composite film prepared in step (1) by means of corona polarization or thermal polarization;

[0055] Wherein, the conditions of the corona polarization injector are as follows: under the condition of keeping the temperature at 110°C, charge with a voltage of 10kV for 5min, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com