High temperature wear resistance antistatic coating

An antistatic and high temperature resistant technology, applied in the direction of conductive coatings, polyester coatings, epoxy resin coatings, etc., can solve the problems of high temperature resistance, wear resistance and impact resistance, and performance impact, etc. Good static electricity, dense coating and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

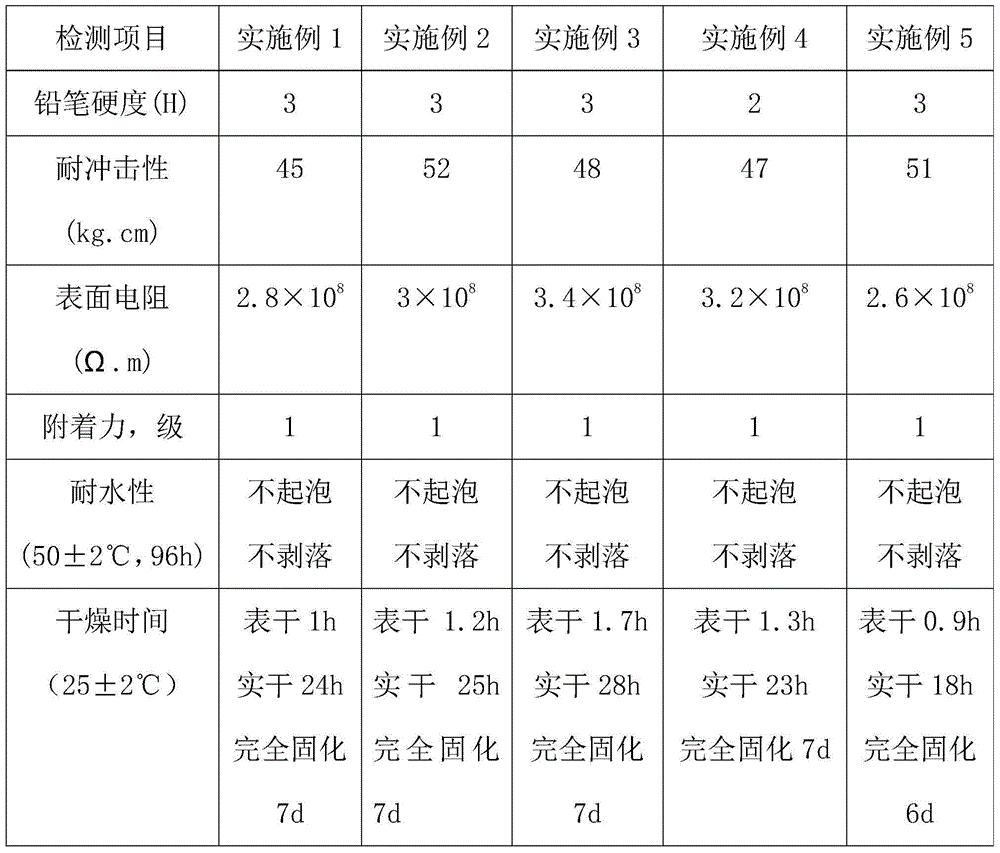

Examples

Embodiment 1

[0021] The present invention proposes a high-temperature-resistant wear-resistant antistatic coating, whose raw materials include the following components by weight: 35 parts of polyphenylene sulfide resin, 35 parts of polyester resin, 10 parts of epoxy resin, and 15 parts of polytetrafluoroethylene , 15 parts of perfluoroethylene propylene resin, 6 parts of carboxyl powdered nitrile rubber, 1 part of amino resin, 10 parts of carbon nanotubes, 8 parts of nano-zinc oxide, 10 parts of carbon black, 2 parts of polyethylene glycol, sorbitol 3 parts of anhydride monofatty acid ester, 1 part of conductive polymer poly-3,4-ethylenedioxythiophene dispersion, 1.2 parts of methyl ethyl ketone oxime, 65 parts of water, 1 part of amino-containing silane coupling agent, 1 part of defoamer , 0.2 parts of thickener, 7 parts of leveling agent, 30 parts of film-forming aid.

Embodiment 2

[0023] The present invention proposes a high-temperature-resistant wear-resistant antistatic coating, whose raw materials include the following components by weight: 60 parts of polyphenylene sulfide resin, 20 parts of polyester resin, 25 parts of epoxy resin, and 2 parts of polytetrafluoroethylene , 30 parts of perfluoroethylene propylene resin, 2 parts of carboxyl powdered nitrile rubber, 3 parts of amino resin, 3 parts of carbon nanotubes, 15 parts of nano-zinc oxide, 3 parts of carbon black, 8 parts of polyethylene glycol, sorbitol 1 part of anhydride monofatty acid ester, 5 parts of conductive polymer poly-3,4-ethylenedioxythiophene dispersion, 0.3 part of methyl ethyl ketone oxime, 30 parts of water, 2.5 parts of amino-containing silane coupling agent, 0.3 part of defoamer , 1 part of thickener, 4 parts of leveling agent, 15 parts of film-forming aid;

[0024] Wherein, the film-forming aid is ethylene glycol monobutyl ether, propylene glycol, mannitol, diacetone alcohol,...

Embodiment 3

[0026] The present invention proposes a high-temperature-resistant wear-resistant antistatic coating, whose raw materials include the following components by weight: 46 parts of polyphenylene sulfide resin, 30 parts of polyester resin, 20 parts of epoxy resin, and 11 parts of polytetrafluoroethylene , 24 parts of perfluoroethylene propylene resin, 3.8 parts of carboxyl powdered nitrile rubber, 2 parts of amino resin, 7.3 parts of carbon nanotubes, 12 parts of nano-zinc oxide, 7.3 parts of carbon black, 5.7 parts of polyethylene glycol, sorbitol 2 parts of anhydride monofatty acid ester, 3.4 parts of conductive polymer poly-3,4-ethylenedioxythiophene dispersion, 1 part of methyl ethyl ketone oxime, 45 parts of water, 1.9 parts of amino-containing silane coupling agent, 0.7 parts of defoamer , 0.6 parts of thickener, 5.8 parts of leveling agent, 125 parts of alcohol ester, 10 parts of dipropylene glycol dimethyl ether, 4 parts of xylene, 1 part of pentaerythritol, 3 parts of ethy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com