Cross-linked fluoroplastic heat-shrinkable tube and preparation method thereof

A technology of heat-shrinkable sleeves and fluoroplastics, which is applied in the field of plastic heat-shrinkable sleeves, can solve the problems of poor radiation resistance, temperature resistance, electrical insulation performance, poor medium resistance, and low expansion ratio, and achieve temperature resistance. high performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A cross-linked fluoroplastic heat-shrinkable sleeve, the preparation method of which is: (1) according to the parts by weight, take 90 parts of ETFE, 5 parts of TAIC, TiO 2 2 parts of pigment, 5 parts of antimony trioxide, and 1 part of low molecular weight PTFE. Cross-linkable fluoroplastic XLETFE particles are prepared by parallel twin-screw mixing and granulation;

[0046] (2) Using the XLETFE particles prepared in step (1), extrude the pipe through the extruder, and the extrusion temperature is set to 285°C;

[0047] (3) irradiating the pipe extruded in step (2) through an electron accelerator, and the irradiation dose is 80kGy;

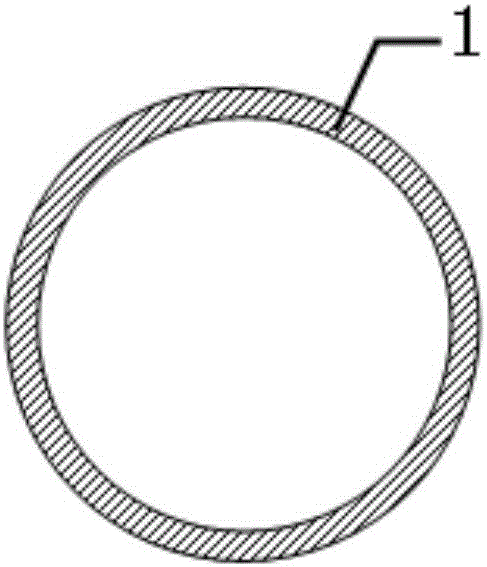

[0048] (4) Heating the pipe material after radiation crosslinking in step (3) to 290°C and expanding it by 4 times to obtain the following: figure 1 Single layer cross-linked fluoroplastic heat shrink tubing shown.

Embodiment 2

[0050] A cross-linked fluoroplastic heat-shrinkable sleeve, the preparation method of which is as follows:

[0051] (1) According to parts by weight, take 20 parts of ETFE, 50 parts of ECTFE, 8 parts of TMT, 2 parts of cadmium yellow pigment, 5 parts of antimony trioxide, 1 part of diatomaceous earth, calcium hydroxide 1 part, silicone additive 1 part, white carbon black 1 part, hindered phenol phosphite compound antioxidant 2 parts, yellow crosslinkable fluoroplastic particles were prepared by parallel twin-screw mixing and granulation;

[0052] (2) Using the yellow crosslinkable fluoroplastic particles prepared in step (1), extrude the pipe through an extruder, and set the extrusion temperature to 295°C;

[0053] (3) irradiating the pipe extruded in step (2) through an electron accelerator, and the irradiation dose is 90kGy;

[0054] (4) Heating the irradiated tube to 290°C and expanding it by 3 times to obtain the following figure 1 Single layer cross-linked fluoroplastic...

Embodiment 3

[0056] A cross-linked fluoroplastic heat-shrinkable sleeve, the preparation method of which is as follows:

[0057] (1) According to parts by weight, take by weighing 50 parts of ECTFE, 5 parts of TMPTMA, 5 parts of iron red, 2 parts of magnesium oxide, 10 parts of antimony trioxide, and 1 part of low molecular weight PTFE. Mixing and granulation to prepare red cross-linkable fluoroplastic particles;

[0058] (2) Using the red cross-linkable fluoroplastic particles prepared in step (1), extrude the pipe through an extruder, and set the extrusion temperature to 310°C;

[0059] (3) irradiating the pipe extruded in step (2) through an electron accelerator, and the irradiation dose is 100kGy;

[0060] (4) Heating the irradiated tube to 290°C and expanding it by 4 times to get the following figure 1 Single layer cross-linked fluoroplastic heat shrink tubing shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com