Bonding and curing process of expanded polytetrafluoroethylene membrane

A polytetrafluoroethylene diaphragm and curing technology, which is applied in the direction of chemical instruments and methods, synthetic resin layered products, lamination devices, etc., can solve the lack of expanded polytetrafluoroethylene diaphragm bonding method and the impact on product quality , Bonding difficulties and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A kind of bonding of the expanded polytetrafluoroethylene diaphragm of the present invention, curing technology, carry out according to the following steps:

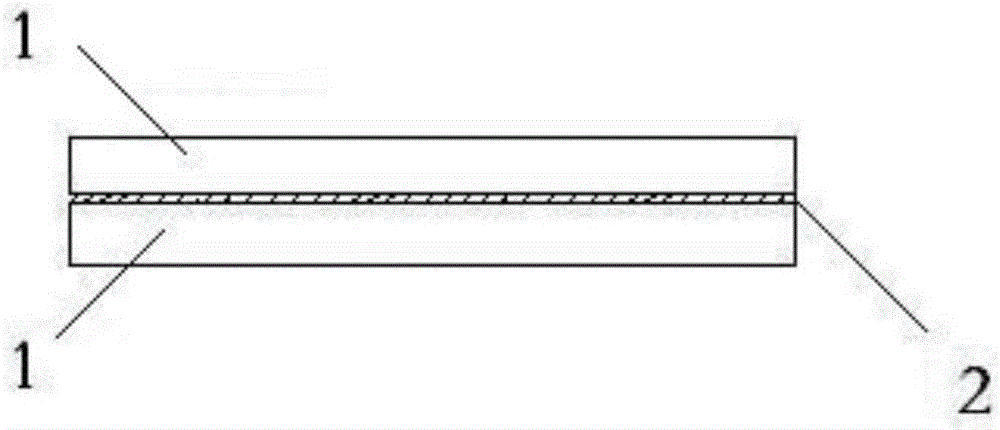

[0029] (1) Select FEP emulsion as the binder, and brush the FEP emulsion between several laminated e-PTFE porous membranes; figure 1 As shown, there is a layer of FEP bonding layer 2 (emulsion, moisture, emulsifier) between every two layers of e-PTFE porous membrane 1 (raw meal); bond several layers of e-PTFE porous membrane to a certain thickness sheet, to obtain the e-PTFE diaphragm composite 3.

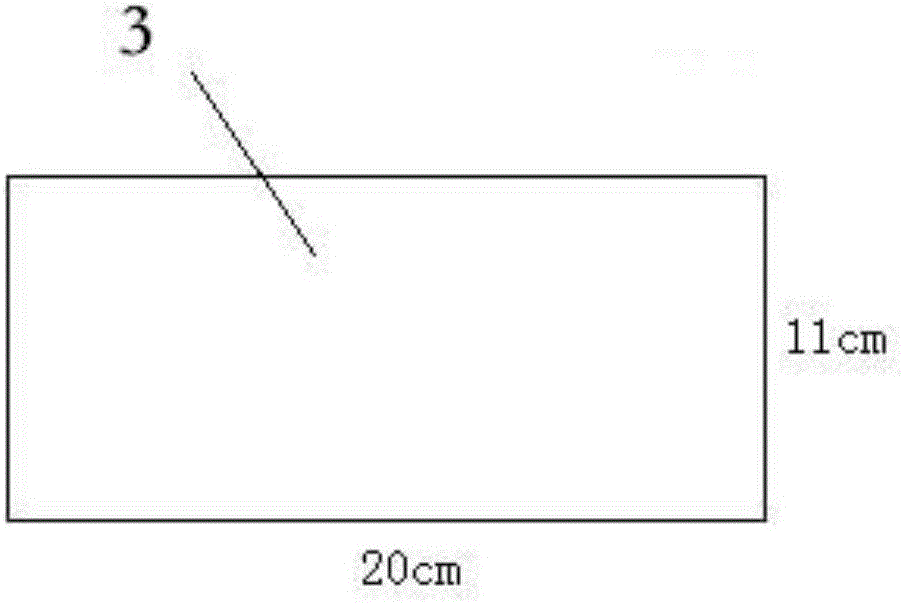

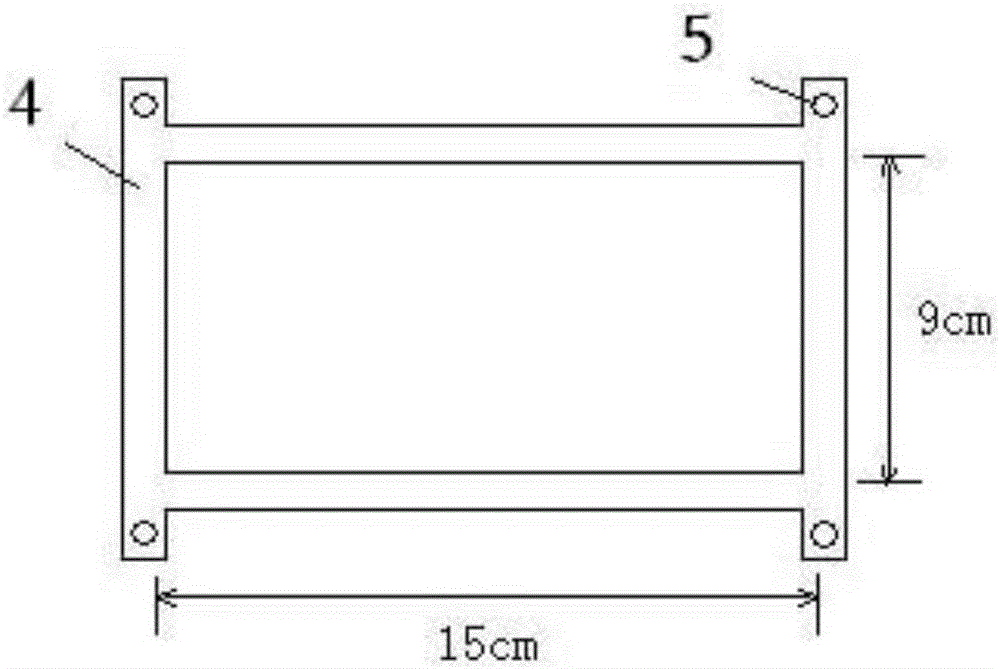

[0030] (2) Place the e-PTFE diaphragm composite in the middle of two frame-type fixtures, and fix the e-PTFE diaphragm composite and the two frame-type fixtures together with screws around them. Such as figure 2 As shown, the size of the e-PTFE diaphragm composite 3 is 20cm*11cm. Such as image 3 As shown, the size of the plate and frame fixing fixture 4 is 15cm*9cm; the material of the plate and frame fixing fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com