Preparation method of super hydrophobic coating based on super hydrophobic silica and resin

A super-hydrophobic coating, silica technology, applied in chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve problems such as poor coating strength and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

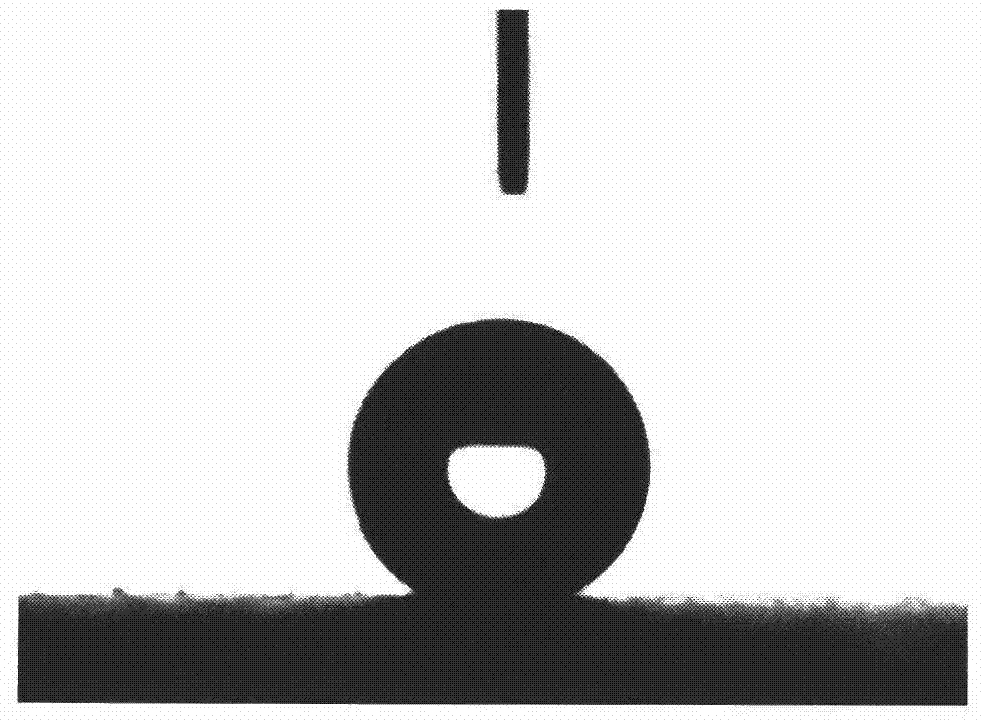

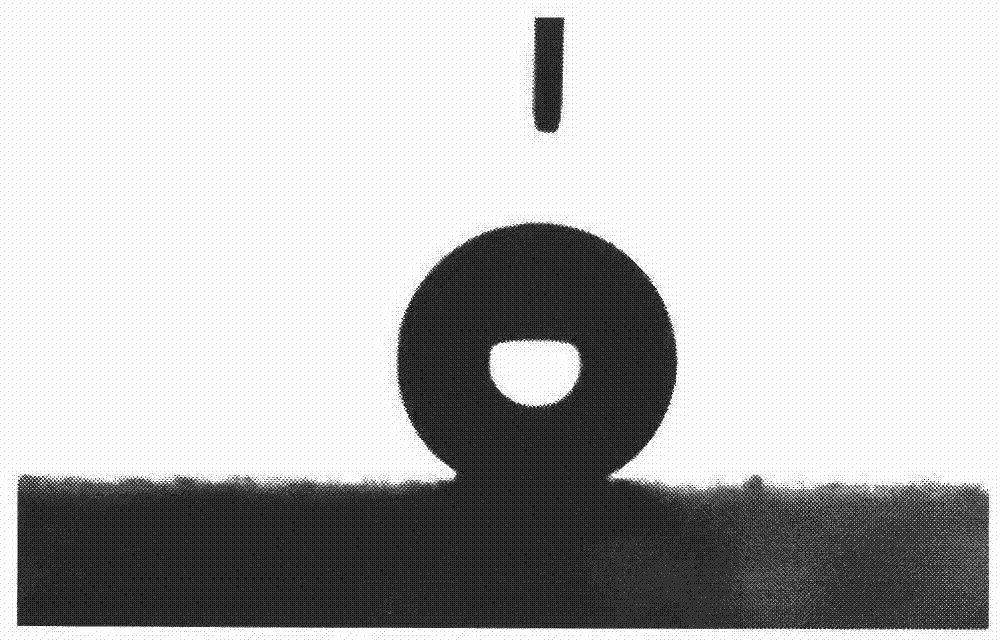

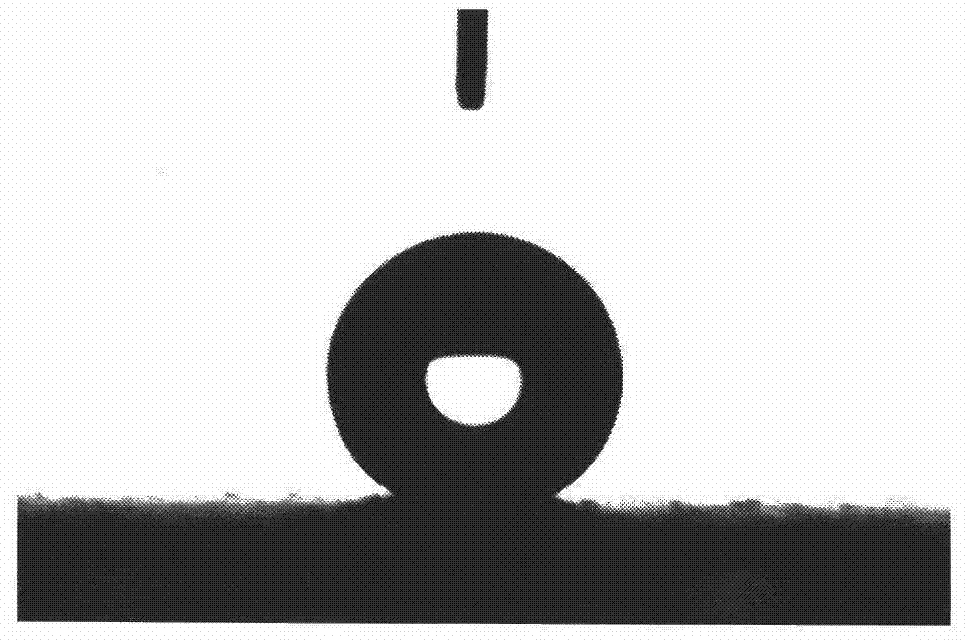

Image

Examples

Embodiment 1

[0020] Silicone resin with a solid content of 50% was coated onto a 1 x 5 cm glass slide as a substrate with a coating thickness of 0.5 mm.

[0021] Add 10 mL of methyltrimethoxysilane to 100 mL of industrially pure methanol, add 5 mL of 0.1 mol / L oxalic acid, stir for 10 minutes, let stand for 3 hours, then add 10 mL of 25% ammonia water, stir for 10 minutes, and Leave for 12 hours. The white precipitate obtained by filtration was washed twice with ethanol, and dried at 80° C. for 5 hours. The obtained particles are ground and filtered through a 200-mesh sieve to obtain methyl-modified white superhydrophobic silicon dioxide particles with a particle size of less than 75 microns, that is, alkyl siloxane.

[0022] The superhydrophobic silica was bonded to the resin by gravity sanding. That is, make the alkylsiloxane particles fall on the glass slide coated with silicone resin from a height of 5 cm directly above the slide glass, so that the alkylsiloxane particles completely ...

Embodiment 2

[0024] A 30% solids epoxy resin was coated onto a 1 x 5 cm glass slide as a substrate with a coating thickness of 0.4 mm.

[0025] Add 10 mL of methyltrimethoxysilane to 100 mL of industrial pure methanol, add 5 mL of 0.1 mol / L oxalic acid, stir for 10 minutes, let stand for 3 hours, then add 10 mL of 25% ammonia water, stir for 10 minutes, let stand 12 hours. The white precipitate obtained by filtration was washed twice with ethanol, and dried at 80° C. for 5 hours. The obtained particles are ground and filtered through a 200-mesh sieve to obtain methyl-modified white superhydrophobic silicon dioxide particles with a particle size of less than 75 microns, that is, alkyl siloxane.

[0026] Use the gravity sanding method to drop the alkylsiloxane particles on the glass slide coated with epoxy resin from a height of 6 cm directly above the glass slide, so that the alkylsiloxane particles completely cover the surface of the epoxy resin, A layer of alkylsiloxane particles forms ...

Embodiment 3

[0028] Polyurethane resin with a solid content of 25% was coated onto a 1 x 5 cm glass slide as a substrate with a coating thickness of 0.4 mm.

[0029] Add 10 mL of methyltrimethoxysilane to 100 mL of industrially pure methanol, add 5 mL of 0.1 mol / L oxalic acid, stir for 10 minutes, let stand for 3 hours, then add 10 mL of 25% ammonia water, stir for 10 minutes, and Leave for 12 hours. The white precipitate obtained by filtration was washed twice with ethanol, and dried at 80° C. for 5 hours. The obtained particles are ground and filtered through a 200-mesh sieve to obtain methyl-modified white superhydrophobic silicon dioxide particles with a particle size of less than 75 microns, that is, alkyl siloxane.

[0030] Using the gravity sanding method, the alkylsiloxane particles are dropped from a height of 11 cm directly above the glass slide on the glass slide coated with polyurethane resin, so that the alkylsiloxane particles completely cover the surface of the polyurethane...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Roll angle | aaaaa | aaaaa |

| Roll angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com