Super-hydrophobic porous polyvinyl chloride film and its preparing process

A polyvinyl chloride film, super-hydrophobic technology, applied in the direction of coating, etc., can solve the problems of expensive, fragile templates, limited industrial application prospects, etc., and achieve easy operation, stable super-hydrophobic properties, and good industrial application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

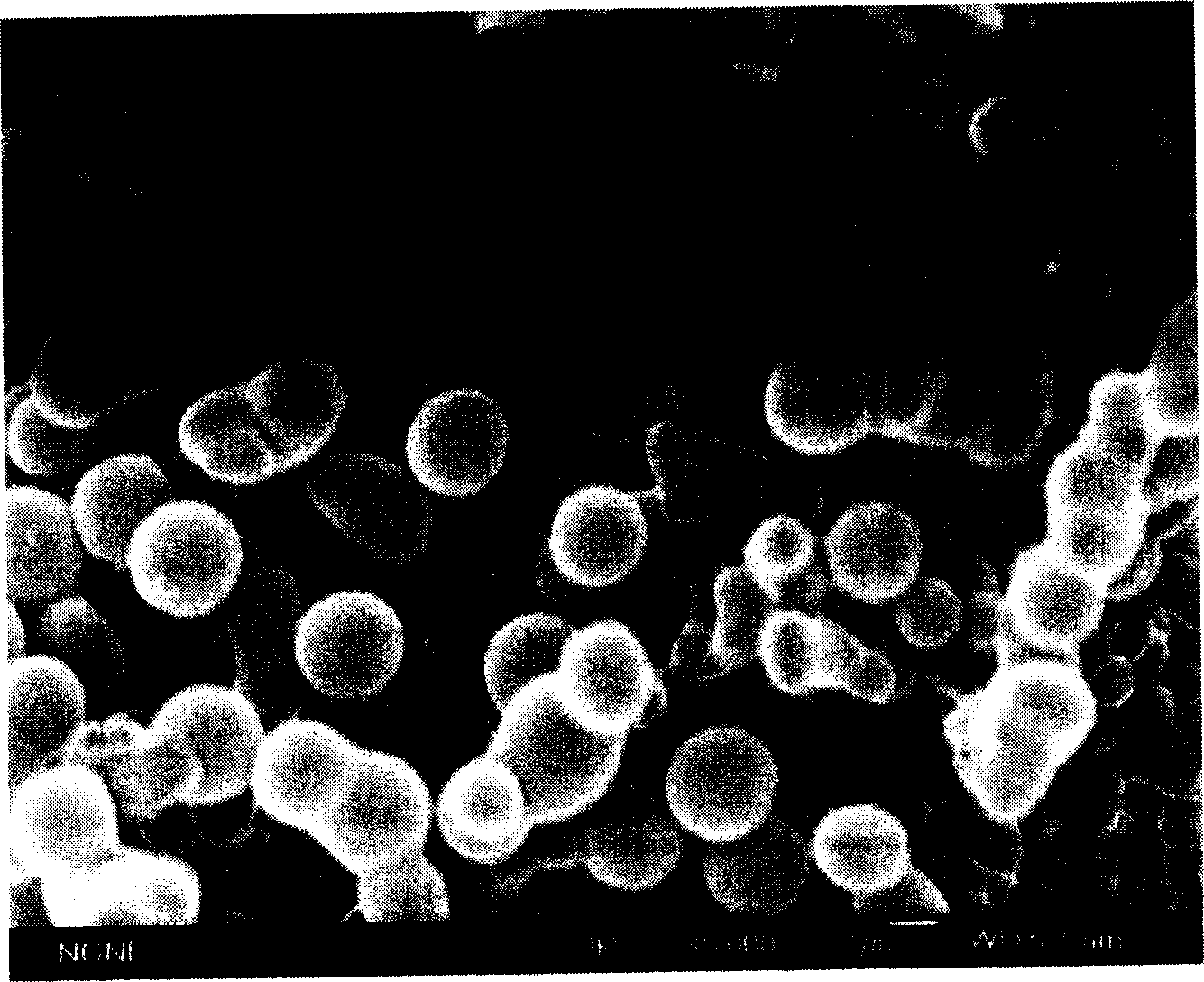

[0028] 1 part of polyvinyl chloride resin was dissolved in 18 parts of tetrahydrofuran. At room temperature, drop about 1 volume of ethanol on the pre-cleaned glass substrate in the petri dish, quickly drop about 1.5 times the volume of polyvinyl chloride solution after scraping, and gently scrape again to make the solvent-precipitant Volatilizes slowly, slowly forming a white porous film with loose structure on the surface of the substrate. After vacuum drying for 2 hours, the surface wettability test of the material was carried out on an optical contact angle measuring instrument (JY-82 type). The contact angle between the obtained polyvinyl chloride film surface and water was 163.6±2.3°, and the rolling angle was 3.9°. JEOL JSM-6700F, AMRAY 1910FE scanning electron microscopy showed that the surface of the polyvinyl chloride membrane is a porous structure of spherical particles, in which the diameter of the particles is 100nm to 1μm, and the pores are about 10nm to 1μm.

Embodiment 2

[0030] According to the operation method and steps of Example 1, the precipitating agent was changed to a mixed solvent of 0.5 volume of ethanol and water (volume ratio of 5:1). The contact angle between the surface of the obtained polyvinyl chloride membrane and water is 161.0±2.0°, the rolling angle is 5°, the surface structure of the membrane is stacked with round particles, the diameter of the particles is 100nm-1μm, and the pores are about 10nm-1μm.

Embodiment 3

[0032] According to the operation method and steps of Example 1, the precipitating agent was changed to a mixed solvent of 0.3 volume of ethanol and water (volume ratio of 2:1). The contact angle between the surface of the obtained polyvinyl chloride membrane and water is 155.3±2.8°, and the rolling angle is 6.7°. The surface structure of the membrane is stacked with oval or round particles, in which the diameter of the particles is 100nm-1μm, and the pores are about 10nm-1μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Porosity | aaaaa | aaaaa |

| Porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com