Method for preparing nickel cobalt lithium aluminate cathode material

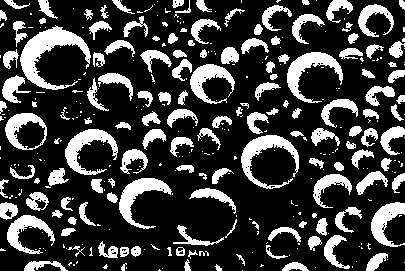

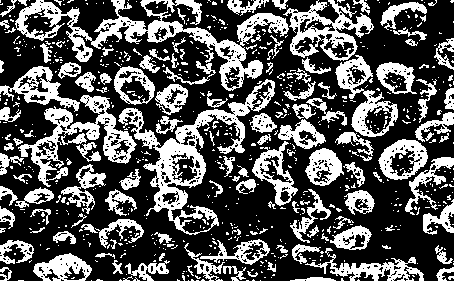

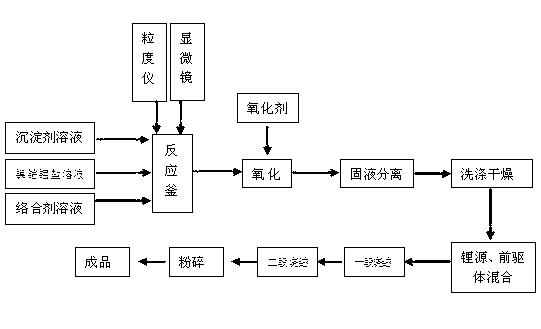

A technology of lithium nickel cobalt aluminate and positive electrode materials, applied in battery electrodes, electrical components, circuits, etc., can solve the problems of unstable material performance, poor electrochemical stability, uneven particle distribution, etc., to simplify the production process, Good spherical shape and good material uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] ①Use pure water to prepare nickel-cobalt-aluminum molar ratio of 0.8:0.15:0.05 and metal ion concentration of 120g / L

[0027] Mixed solution, nickel cobalt aluminum solution preparation with nickel sulfate, cobalt sulfate, aluminum nitrate.

[0028] ② Prepare 150g / L sodium hydroxide solution with pure water.

[0029] ③ Prepare 2mol / L ammonia water with liquid ammonia.

[0030] Prepare the bottom solution containing ammonia water and sodium hydroxide, control the pH value at 10.15, the concentration of ammonia water is 6-8g / L, the temperature is 58-62°C, the stirring speed is 120r / min, through ① solution, ② solution, ③ solution The metering pump feeds at the same time, open the solid content regulating valve, and when the solid content is controlled at 160-1800g / L, open the overflow discharge valve, observe the spherical shape through the particle size analyzer and microscope during the precipitation reaction, and adjust the pH value and ammonia water in time concentra...

Embodiment 2

[0033] ① Use pure water to prepare a mixed solution with a molar ratio of nickel-cobalt-aluminum elements of 0.7:0.2:0.1 and a metal ion concentration of 150g / L. The nickel-cobalt-aluminum solution is prepared with nickel nitrate, cobalt nitrate, and aluminum nitrate.

[0034]② Prepare 120g / L sodium hydroxide solution with pure water.

[0035] ③ Prepare 3mol / L ammonia water with liquid ammonia.

[0036] Prepare the bottom solution containing ammonia water and sodium hydroxide, control the pH value at 10.05, the concentration of ammonia water is 6-8g / L, the temperature is 55-59°C, the stirring speed is 120r / min, pass through ① solution, ② solution, ③ solution The metering pump feeds at the same time, open the solid content regulating valve, and when the solid content is controlled at 180-200g / L, open the overflow discharge valve, observe the spherical shape through the particle size analyzer and microscope during the precipitation reaction, and adjust the pH value and ammonia w...

Embodiment 3

[0039] ① Use pure water to prepare a mixed solution with a molar ratio of nickel-cobalt-aluminum elements of 0.75:0.15:0.1 and a metal ion concentration of 120g / L. The nickel-cobalt-aluminum solution is prepared with nickel nitrate, cobalt nitrate, and aluminum nitrate.

[0040] ② Prepare 150g / L sodium hydroxide solution with pure water.

[0041] ③ Prepare 3mol / L ammonia water with liquid ammonia.

[0042] Prepare the bottom solution containing ammonia water and sodium hydroxide, control the pH value at 10.35, and the concentration of ammonia water at 9-11g / L,

[0043] The temperature is 58-62°C, the stirring speed is 120r / min, and the metering pumps of ①solution, ②solution, and ③solution are fed simultaneously, and the solid content regulating valve is opened. When the solid content is controlled at 180-200g / L, the overflow outlet is opened. Material valve, during the precipitation reaction process, observe the spherical shape through the particle size analyzer and microscop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com