Method for recovering valuable metal from waste lithium ion battery material

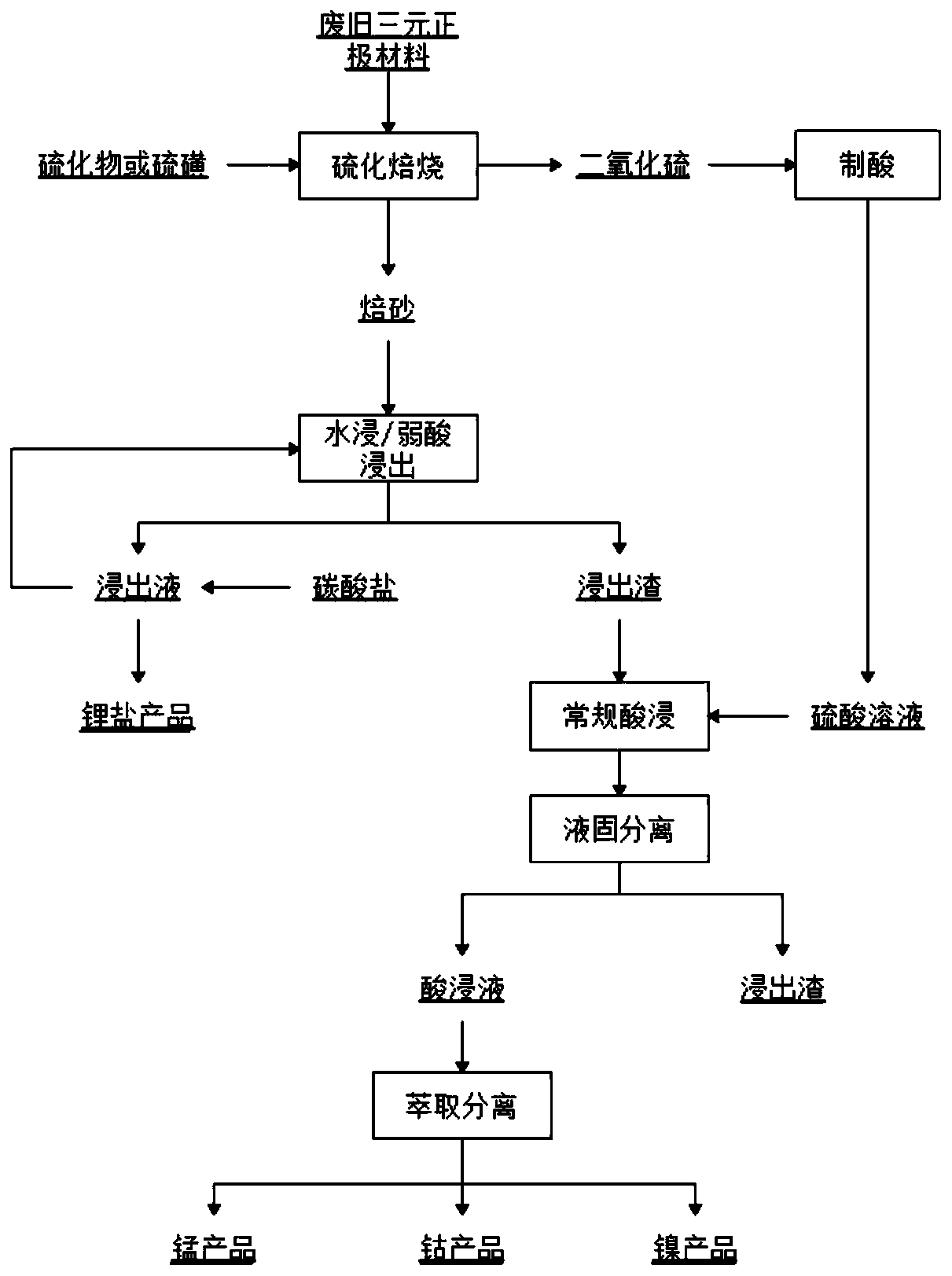

A technology for lithium-ion batteries and valuable metals, which is applied in the field of recycling and comprehensive recycling of electronic waste, can solve the problems of increased reagent costs, increased concentration energy consumption, and increased liquid-solid ratio, reducing reagent consumption and reducing Energy consumption, the effect of simplifying the subsequent separation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Take 100g of the positive electrode material of waste lithium batteries and add sulfur according to the mass ratio of 10%, mix evenly, and then roast at 650°C for 120min to obtain vulcanized calcined sand, leaching the vulcanized calcined sand by water immersion at a temperature of 95°C for 120min, and filter The water leaching solution and water leaching residue were obtained, the leaching rate of lithium was 85%, the water leaching residue was leached at 95°C for 120min with an acid solution with a sulfuric acid concentration of 2mol / L, and the leaching rate of nickel and cobalt was 95%, and the leaching solution was removed by alum method. P204 is used for extraction and removal of impurities after iron, and the liquid after removal of impurities is extracted and separated from cobalt and nickel by P507.

Embodiment 2

[0032] Take 100g of the positive electrode material of waste lithium battery and add sulfur according to the mass ratio of 10%, mix evenly, and then roast at 650°C for 120min to obtain vulcanized calcined sand, leaching the vulcanized calcined sand by weak acid leaching method, the pH of the weak acid leach solution is 5.0, and the leaching temperature is 95 ℃, time 120min, filter to obtain water leaching liquid and water leaching residue, lithium leaching rate reaches 88.50%, water leaching residue is leached at 95 ℃ for 120min with acid solution with sulfuric acid concentration 2mol / L, and a small amount of hydrogen peroxide, nickel The leaching rate of cobalt is up to 98%. The leaching liquid is extracted and removed by P204 after removing iron by the vitriol method. After the removal of impurities, the liquid is extracted and separated by P507 to separate cobalt and nickel.

Embodiment 3

[0034]Take 100g of the positive electrode material of waste lithium batteries and add sulfur according to the mass ratio of 10%, mix evenly, and then roast at 700°C for 120min to obtain vulcanized calcined sand, leaching the vulcanized calcined sand by water immersion at a temperature of 95°C for 120min, and filter The water leaching solution and water leaching residue are obtained, the leaching rate of lithium reaches 85%, after 5 cycles of the water immersion solution, the concentration of lithium in the leaching solution can reach more than 20g / L, and the water leaching residue adopts acid solution with a sulfuric acid concentration of 2mol / L After leaching at 95°C for 120 minutes, the leaching rate of nickel and cobalt reaches 95%. The concentration of nickel in the leaching solution is about 22g / L, and the concentration of cobalt is about 11g / L. The liquid is extracted by P507 to separate cobalt and nickel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com