Assistant for polycarboxylic acid water reducing agent and preparation method thereof

A technology of polycarboxylic acid and water-reducing agent, which is applied in the field of material preparation, can solve problems such as unseen, reaction conditions limit industrialization promotion, reduce PC water-reducing effect, etc., and achieve the effect of simple reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

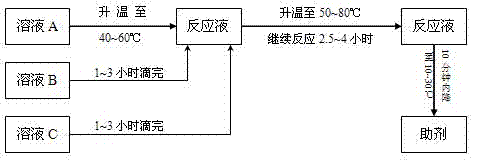

Method used

Image

Examples

Embodiment 1

[0036] 12.5 grams of 3-mercaptopropionic acid, 2.5 grams of EDTA, 10 grams of sodium phosphate and 750 grams of water were added to a 3-liter reactor with stirring, and the temperature began to rise. After the temperature was raised to 40°C, solutions B and C were added dropwise, wherein solution B consisted of 89 grams of methacrylamide, 861 grams of diallylamine and 375 grams of water, solution C was 22.5 grams of azobisisobutyronitrile, 2.5 grams of ascorbic acid and 375 grams of water. Adding time is controlled at 3 hours. After the solution B and C are added dropwise, continue to heat up to 50°C, and after 4 hours of reaction, cool down to below 30°C within 10 minutes, and then obtain the auxiliary agent for inhibiting the adverse effects of clay, with a solid content of 40%. The number average molecular weight measured by gel permeation chromatography was 500.

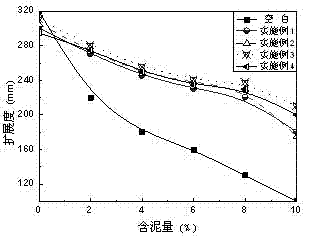

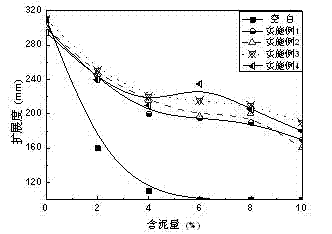

[0037] In the cement paste test, the example was mixed with 40% PC water reducer at a ratio of 1:5. W...

Embodiment 2

[0040] 37.5 grams of thioglycolic acid, 2.5 grams of EDTA, 15 grams of isobutanol and 700 grams of water were stirred into a 3-liter reactor, and the temperature began to rise. After the temperature was raised to 50°C, solutions B and C were added dropwise. Wherein B solution is composed of 72 grams of acrylamide, 978 grams of dimethyl allylamine and 300 grams of water; C solution is 66.5 grams of hydrogen peroxide, 28.5 grams of sodium bisulfite and 300 grams of water. Solution B and C dropwise control in 2 hours. Continue to raise the temperature to 60°C. After reacting for 3.5 hours, cool down to below 30°C within 10 minutes, and then get the auxiliary agent for suppressing the adverse effects of clay, the solid content is 48%, and the number average molecular weight is measured by gel permeation chromatography. for 620.

[0041] In the cement slurry test, the example was mixed with 40% PC water reducing agent at a ratio of 1:5. When the mud content was 0, the init...

Embodiment 3

[0044] 25 grams of mercaptoethanol, 4 grams of EDTA, 18.5 grams of triethanolamine, and 600 grams of water were added to a 3-liter reactor with stirring, and the temperature began to rise. After the temperature was raised to 60°C, solutions B and C were added dropwise. Wherein B solution is composed of 95 grams of acrylamide, 1080 grams of dimethylaminoethyl methacrylate and 275 grams of water; C solution is 102 grams of benzoyl peroxide, 25.5 grams of formaldehyde and 275 grams of water. Adding time is controlled at 1 hour. Raise the temperature to 70°C, continue the reaction for 2.5 hours, then cool down to below 30°C within 10 minutes, and then get the auxiliary agent for suppressing the adverse effects of clay, the solid content is 54%, and the number average molecular weight is measured by gel permeation chromatography for 840.

[0045] In the cement paste test, the embodiment is mixed with 40% PC water reducer at a ratio of 1:5. When the mud content is 0, the in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com