Hydrophobic associating polymer containing capsaicine and sulfonic group and preparation method thereof

A technology of hydrophobic association and sulfonic acid group, which is applied in the direction of drilling compositions, chemical instruments and methods, and can solve problems such as loss of viscosity and decrease in salt resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

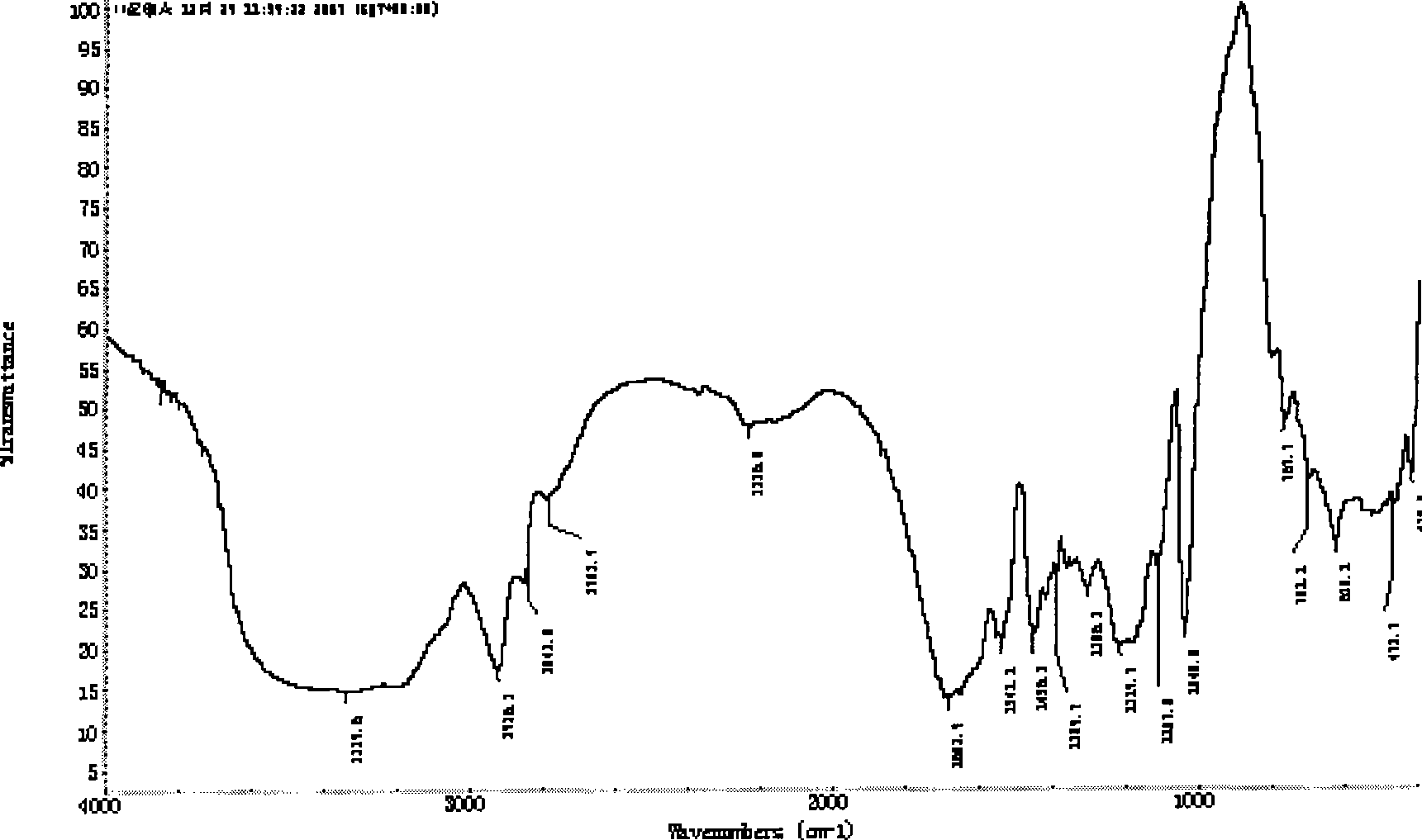

Image

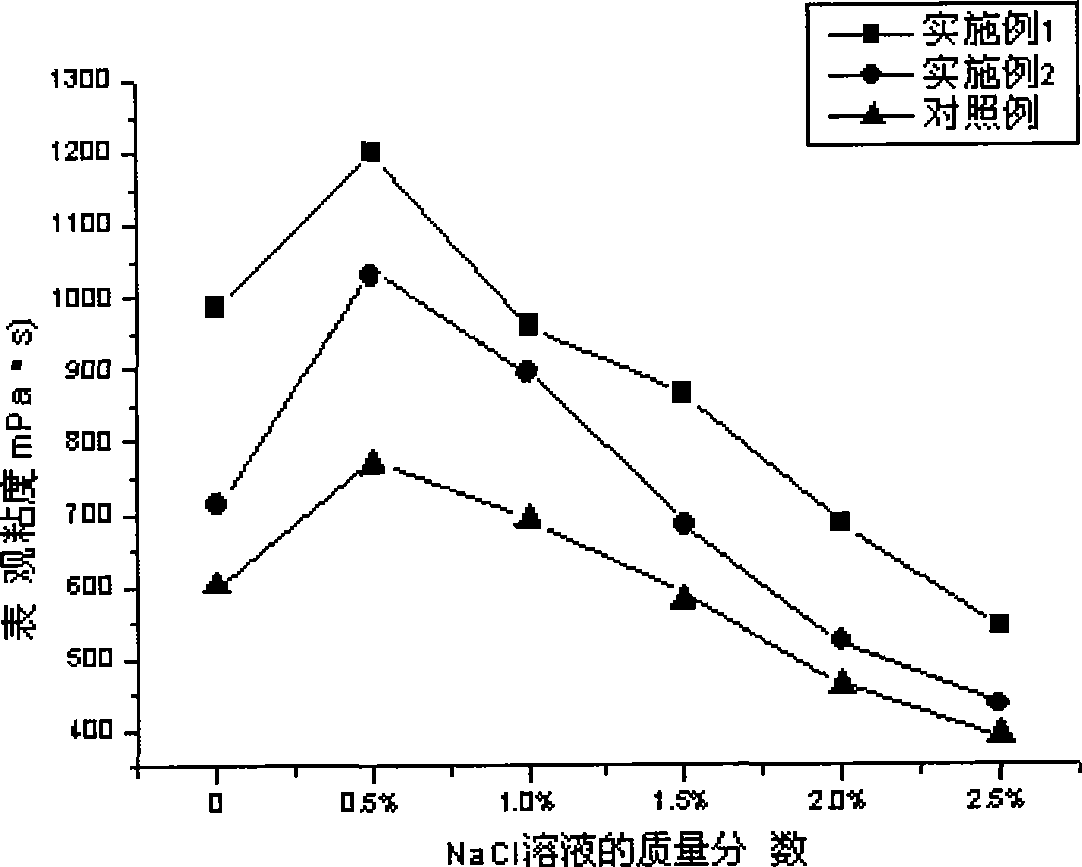

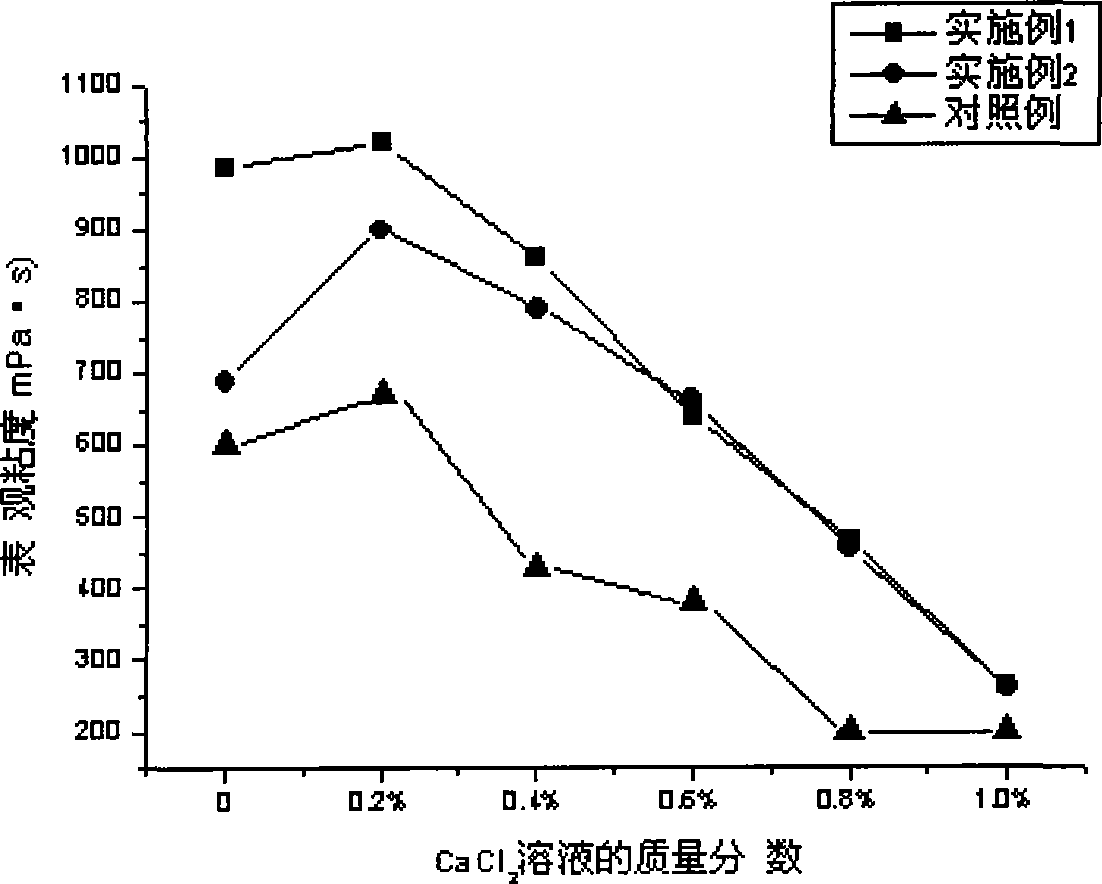

Examples

Embodiment 1

[0015] In a 500ml three-neck flask, add 1.3×10 -3 10 mL of ethanol solution of compound N-(4-hydroxy-3-methoxy-phenylmethyl)acrylamide (HMBA) containing capsaicin functional group, 100 mL of aqueous solution containing 0.1 mol of acrylamide, 0.03 mol of sodium hydroxide Neutralized (neutralization degree 100%) 2-acrylamido-2-methylpropanesulfonic acid (AMPS) aqueous solution 30mL and 1.0×10 -3 mol of (meth)acrylic acid long-chain fatty alcohol ester octadecyl acrylate, stirred at 70°C to make it evenly mixed, then added 0.039g redox initiator K 2 S 2 o 8 and NaHSO 3 , the mass ratio of the two is 2:1, after stirring until the viscosity of the solution increases significantly, the airtight constant temperature is reacted at 70°C for 10 hours, and the hydrophobic olefin containing HMBA-acrylamide-AMPS-acrylic acid tetramembered monomer of the present invention is obtained. Polymer, its number average molecular weight is 50000, dispersion coefficient d is 1.8.

Embodiment 2

[0017] In a three-neck flask, add 1×10 -3 mol of compound N-(4-hydroxy-3-methylthio-benzyl)-acrylamide containing capsaicin functional group in ethanol solution 10mL, aqueous solution containing 0.1mol acrylamide in 100mL, containing 0.03mol is neutralized by sodium hydroxide (Neutralization degree 100%) 2-acrylamido-2-methylpropanesulfonic acid (AMPS) aqueous solution 30mL and 1.1×10 -3 mol of (meth)acrylic acid long-chain fatty alcohol ester octadecyl acrylate, stirred at 100°C to make it evenly mixed, then added 0.039g redox initiator K 2 S 2 o 8 and NaHSO 3 , the mass ratio of the two is 3:1. After stirring until the viscosity of the solution increases significantly, the airtight constant temperature is reacted at 50°C for 8 hours to obtain N-(4-hydroxy-3-methylthio-benzyl)-acrylamide-AMPS- The hydrophobic association copolymer of tetradecyl acrylate monomers has a number average molecular weight of 45000 and a dispersion coefficient d of 1.7.

[0018] The compound co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| polydispersity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com