Polyisoprene aqueous emulsion and method for preparing glove and related products

A polyisoprene water-based, polyisoprene technology, used in gloves, applications, clothing, etc., to achieve the effects of stable emulsion, less gel precipitation, and easy demolding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

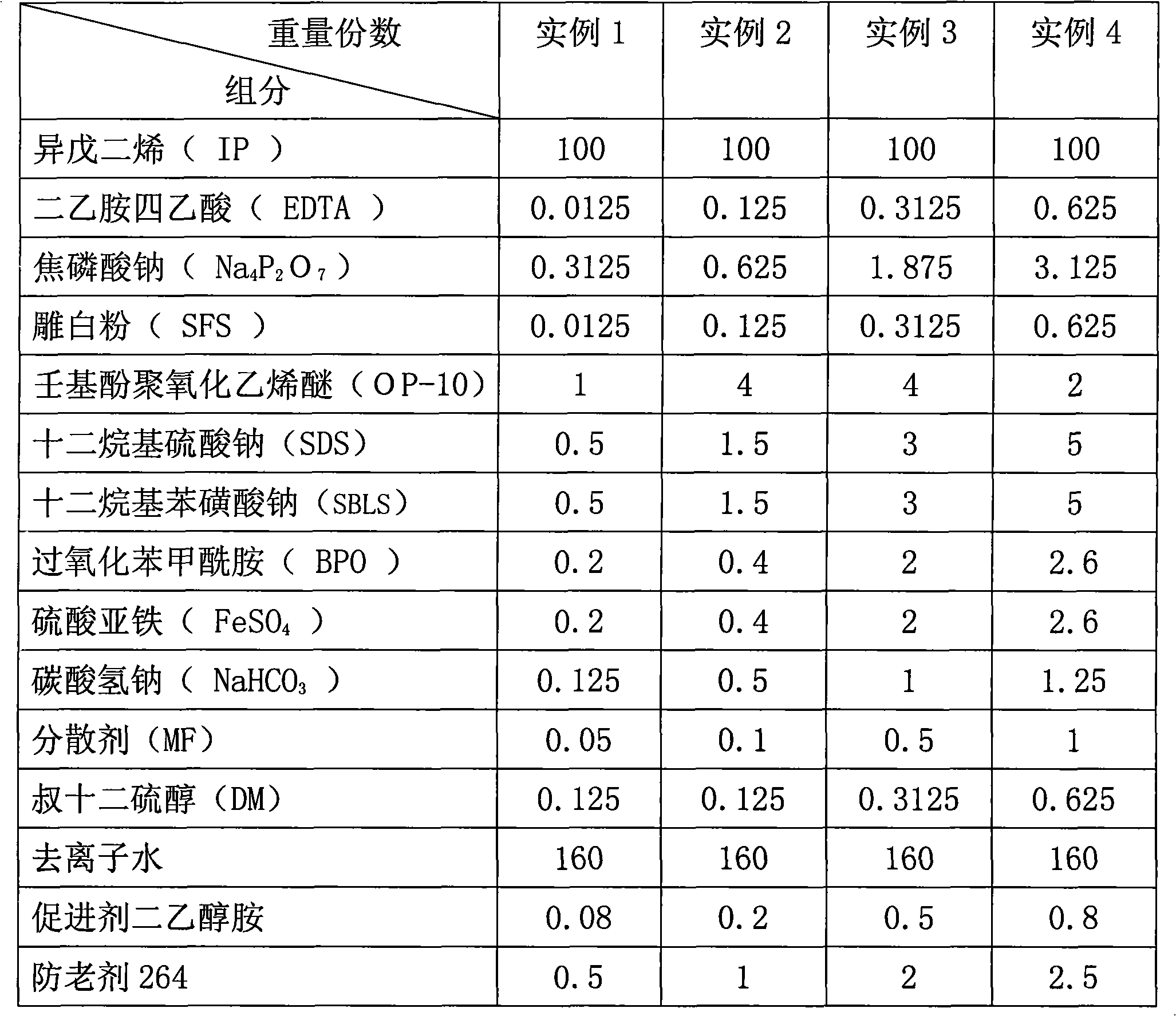

Examples

example 1

[0081]After feeding nitrogen to the bottom of the polymerization kettle for 15 minutes, add 110 parts of deionized water to the polymerization kettle, then add all diethylaminetetraacetic acid (EDTA), sodium dodecylbenzene sulfonate (SBLS), dodecylbenzene in Table 1 Sodium Alkyl Sulfate (SDS), Dispersant (MF), Tert-Dodecyl Mercaptan (DM), Sodium Pyrophosphate, NaHCO3, Sculpture White Powder (SFS) are stirred and dissolved to make water phase, Isoprene Monomer (IP) Stir and dissolve with benzamide peroxide (BPO) to form an oil phase; 50 parts of deionized water and ferrous sulfate (FeSO 4 ) was stirred and dissolved to form an aqueous phase.

[0082] Control the reaction temperature from 10°C to 30°C, and perform the first-stage dropwise addition. The first-stage dropwise addition of isoprene monomer (IP) and benzamide peroxide (BPO) is 5 wt. %, synchronously drop ferrous sulfate (FeSO 4 ) amount of its total amount of 5wt%, after the first stage dropwise, reacted 3h. After ...

example 2

[0084] After feeding nitrogen to the bottom of the polymerization kettle for 15 minutes, add 110 parts of deionized water to the polymerization kettle, then add all diethylaminetetraacetic acid (EDTA), sodium dodecylbenzene sulfonate (SBLS), dodecylbenzene in Table 1 Sodium alkyl sulfate (SDS), dispersant (MF), tertiary dodecyl mercaptan (DM), sodium pyrophosphate, NaHCO3, carved white powder (SFS), stirring and dissolving to form a water phase, isoprene monomer (IP ) and benzamide peroxide (BPO) were stirred and dissolved to form an oil phase; 50 parts of deionized water and ferrous sulfate (FeSO 4 ) was stirred and dissolved to form an aqueous phase.

[0085] Control the reaction temperature at 10°C to 30°C, and perform the first-stage dropwise addition. In the first stage, the mixing amount of isoprene monomer (IP) and benzamide peroxide (BPO) is 8wt of its total mixing amount %, synchronously drop ferrous sulfate (FeSO 4 ) amount of its total amount of 8wt%, after the fi...

example 3

[0087] After feeding nitrogen to the bottom of the polymerization kettle for 15 minutes, add 110 parts of deionized water to the polymerization kettle, then add all the diethylaminetetraacetic acid (EDTA), sodium dodecyl sulfate (SDS), dodecyl Sodium benzenesulfonate, dispersant (MF), tert-dodecyl mercaptan (DM), sodium pyrophosphate, NaHCO3, Sculpture powder (SFS), stirred and dissolved to form a water phase, isoprene monomer (IP) and Benzamide oxide (BPO) was stirred and dissolved to form an oil phase; 50 parts of deionized water and ferrous sulfate (FeSO 4 ) was stirred and dissolved to form an aqueous phase.

[0088] Control the reaction temperature from 10°C to 30°C, and perform the first-stage dropwise addition. The first-stage dropwise addition of isoprene monomer (IP) and benzamide peroxide (BPO) is 12wt of its total amount. %, synchronously drop ferrous sulfate (FeSO 4 ) amount of its total amount of 12wt%, after the first stage dropwise, reacted 1h. After the firs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com