Lubricant for improved surface quality of cast aluminum and method

a technology of lubricant and cast aluminum, which is applied in the direction of lubricant composition, snowboard binding, sport apparatus, etc., can solve the problems of cracks, surface imperfections, and expensive remedial rework or scrapping of cracked materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

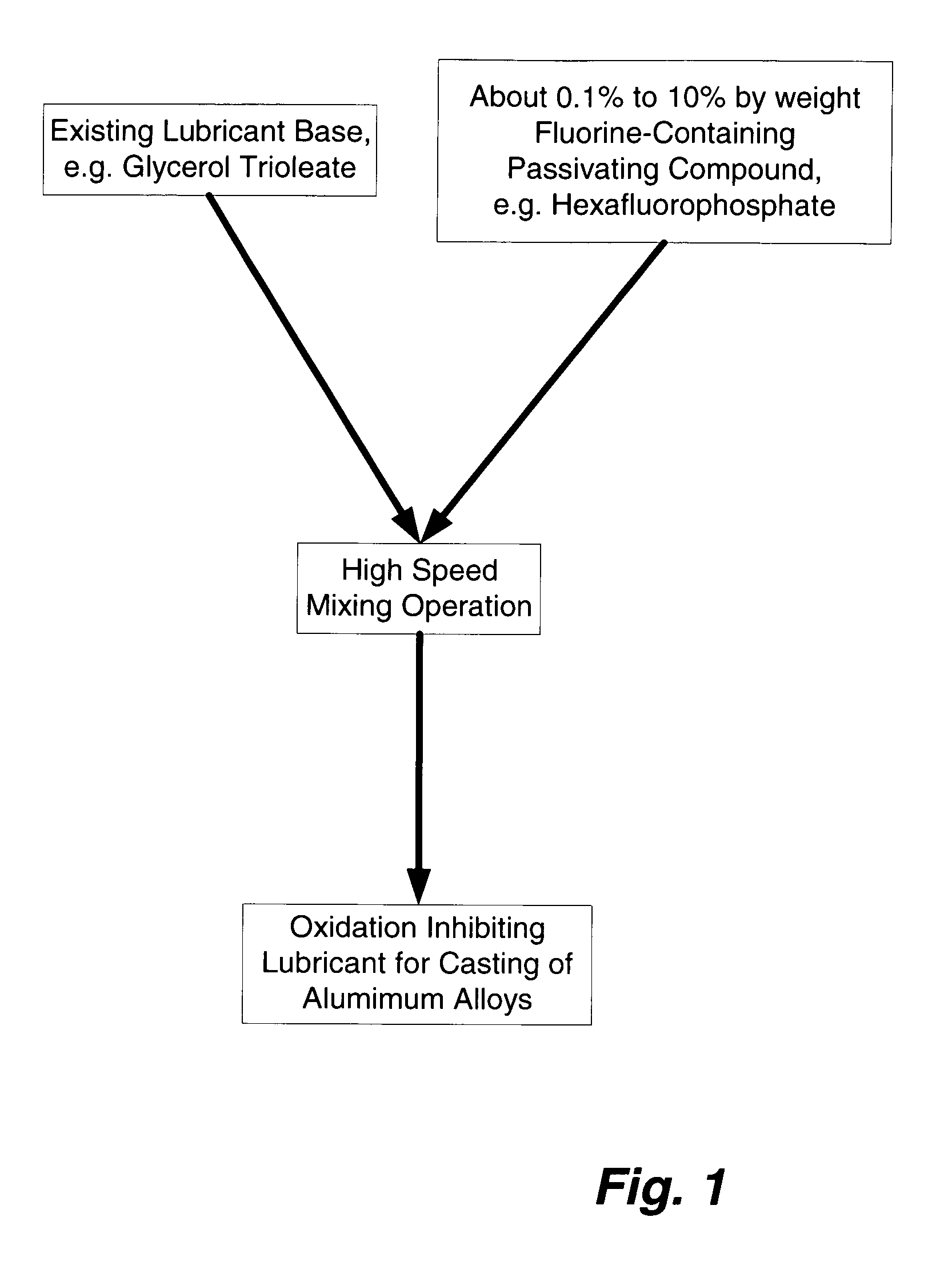

Method used

Image

Examples

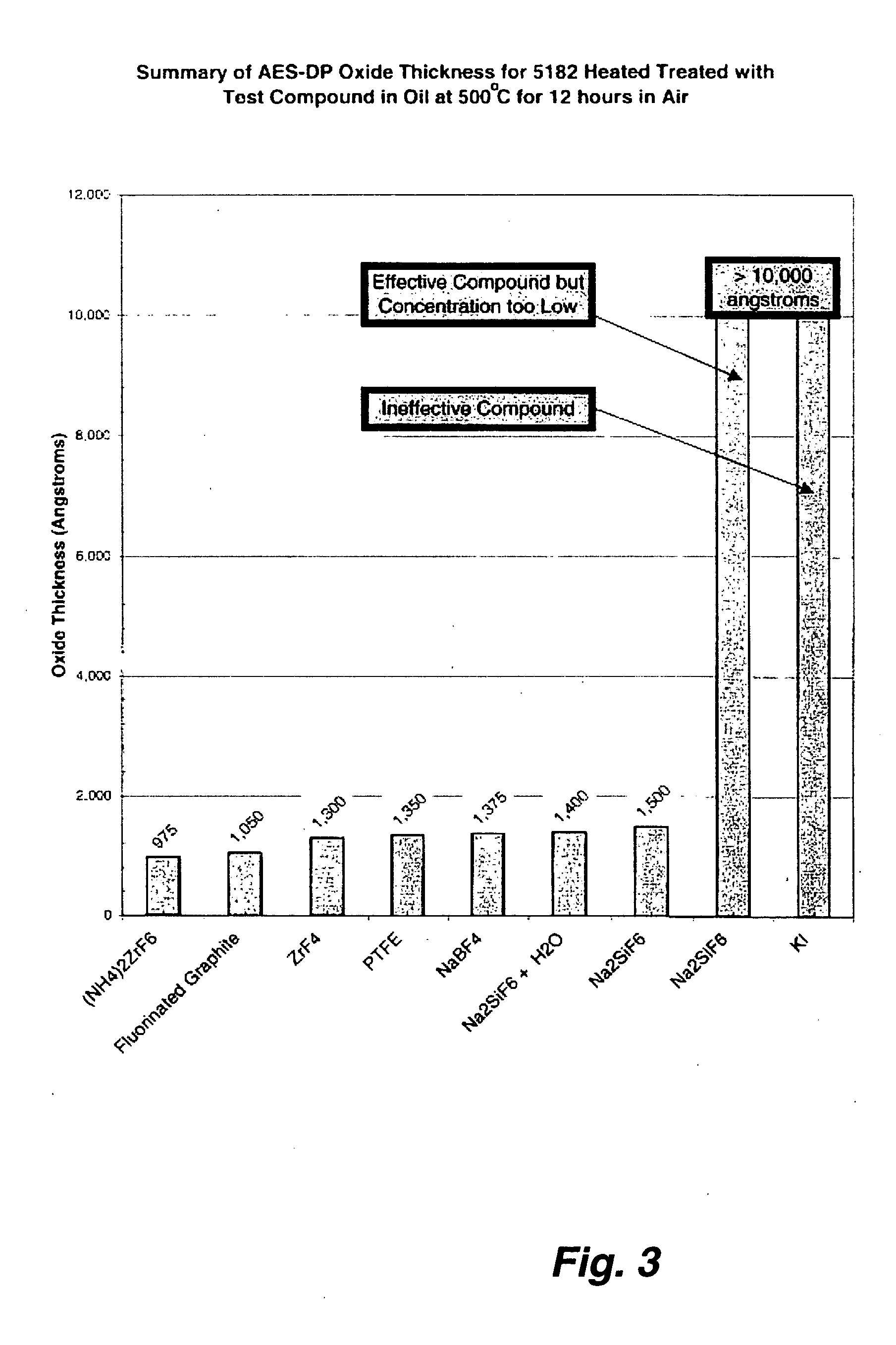

example 1

[0047] About 1% by weight of ammonium fluozirconate was added to a glycerol trioleate base. The mixture was sheared in a high speed blender for about 5 minutes. After placing the lubricant on the 5182 sheet and heating as described above, the oxide thickness was measured as 975 Angstroms (Å).

example 2

[0048] About 1% by weight of fluorinated graphite was added to a glycerol trioleate base. The mixture was sheared in a high speed blender for about 5 minutes. After placing the lubricant on the 5182 sheet and heating as described above, the oxide thickness was measured as 1,050 Angstroms (Å).

example 3

[0049] About 1% by weight of zirconium tetrafluoride was added to a glycerol trioleate base. The mixture was sheared in a high speed blender for about 5 minutes. After placing the lubricant on the 5182 sheet and heating as described above, the oxide thickness was measured as 1,300 Angstroms (Å).

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com