Heat exchanger tube

A technology of heat exchangers and tubes, which is applied in the field of tube-and-tube heat exchangers, and can solve problems such as tube corrosion or damage, and unsatisfactory cleaning effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below through the description of specific embodiments with reference to the accompanying drawings.

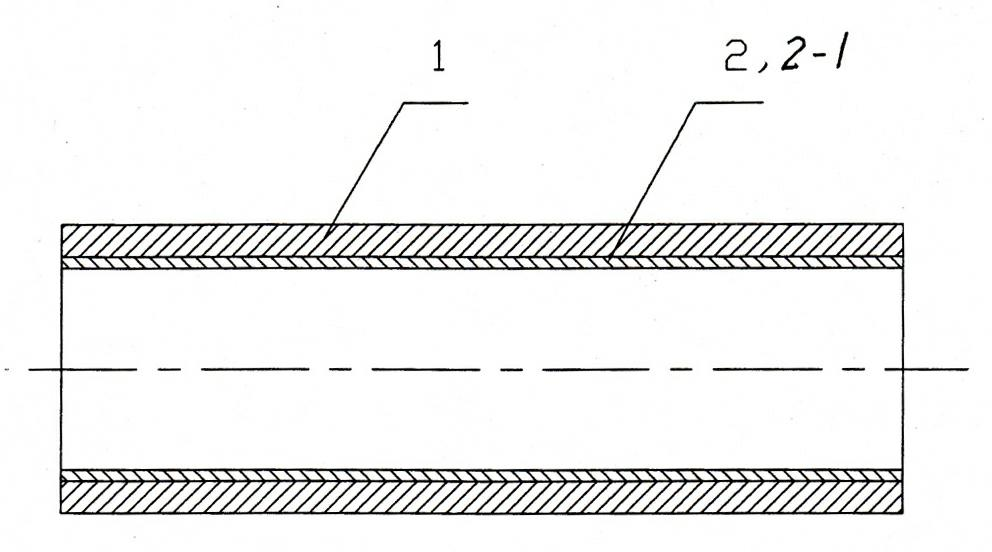

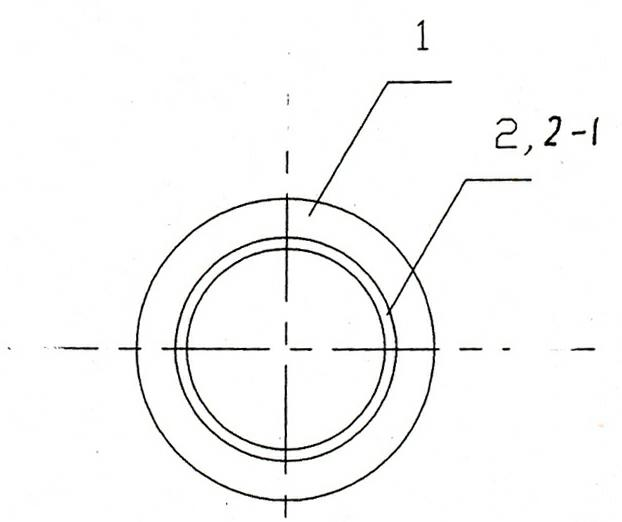

[0026] One of the specific implementation modes, as attached figure 1 , 2 shown.

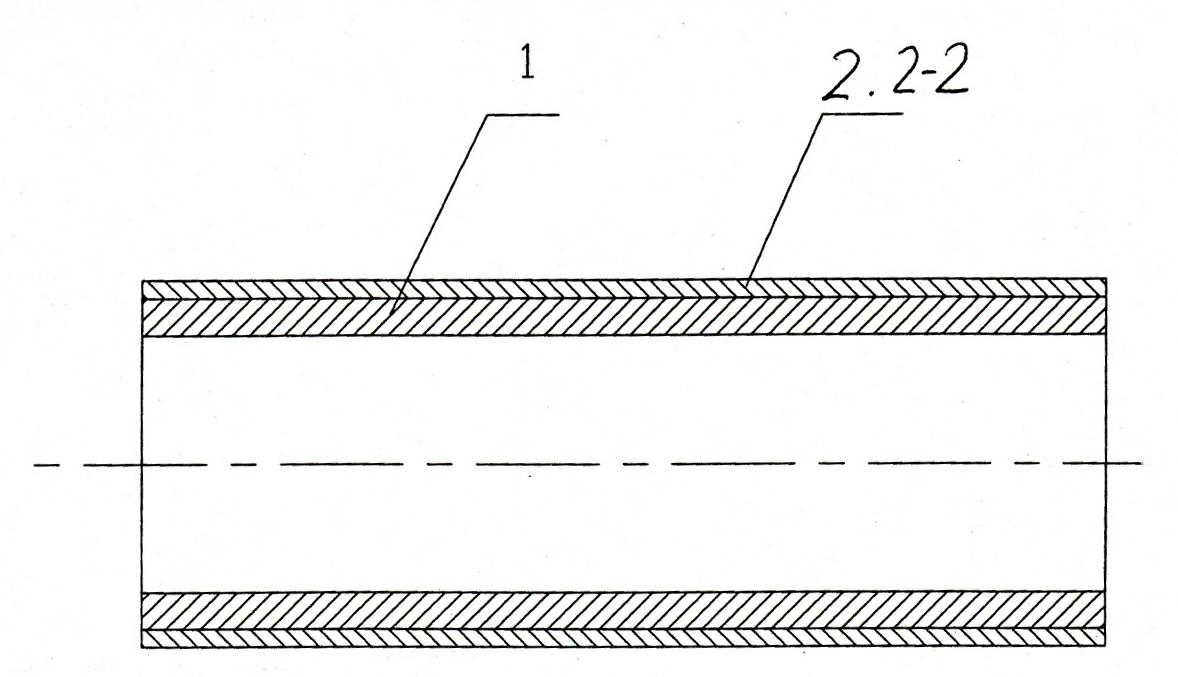

[0027] A tube array of a heat exchanger includes a tube body 1 on which a shape memory alloy thin film 2 is pasted. The shape memory alloy film 2 is a thermally expandable shape memory alloy film 2 - 1 , and the thermally expandable shape memory alloy film 2 - 1 is attached to the inner wall of the tube body 1 . Moreover, the heat-expandable shape memory alloy film 2-1 is formed of a sheet-shaped heat-expandable shape memory alloy thin plate, which is rounded and pasted on the inner wall of the pipe body 1 and connected with a slit opening to form a tubular structure. The heat-expandable shape memory alloy thin plate is a titanium-nickel alloy thin plate, and its thickness is in the range of 0.1-0.2 mm. The opening width of the heat-expan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com