Flame cutting system with insulation device for flame cutting zone of billet

A technology of flame cutting and heat preservation device, used in gas flame welding equipment, welding equipment, metal processing equipment and other directions, can solve the problems of prolonged cutting time, complex mechanism, low billet drawing speed, etc., to ensure performance and strength, solve the problem of shaft The effect of end sealing and preventing damage to the roller table

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

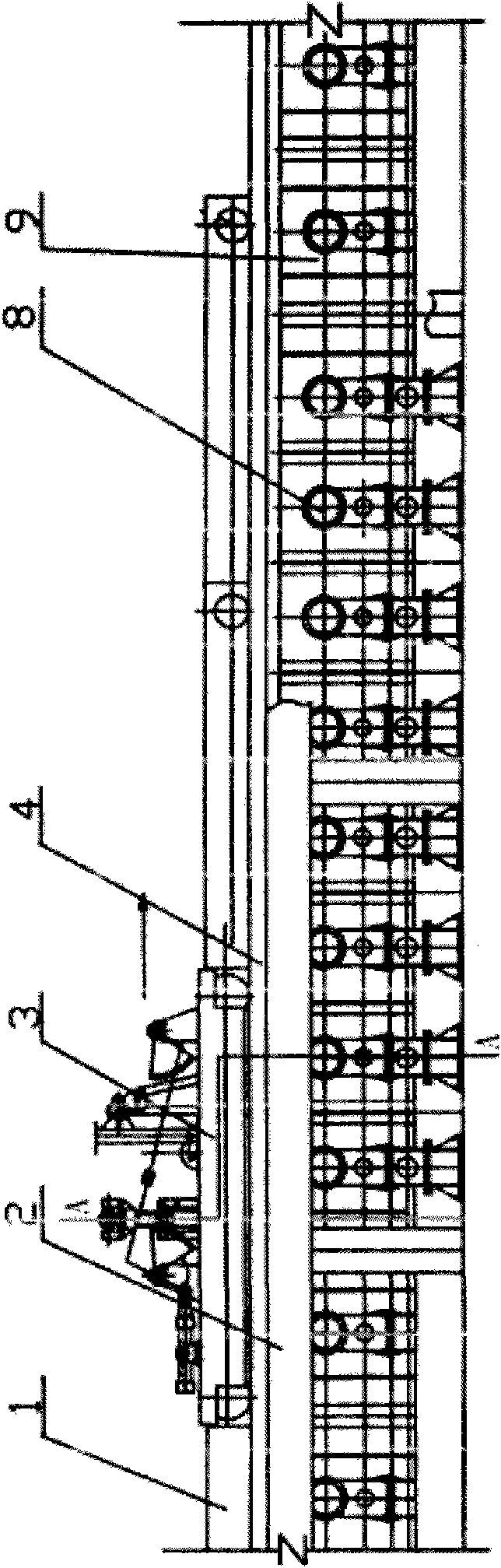

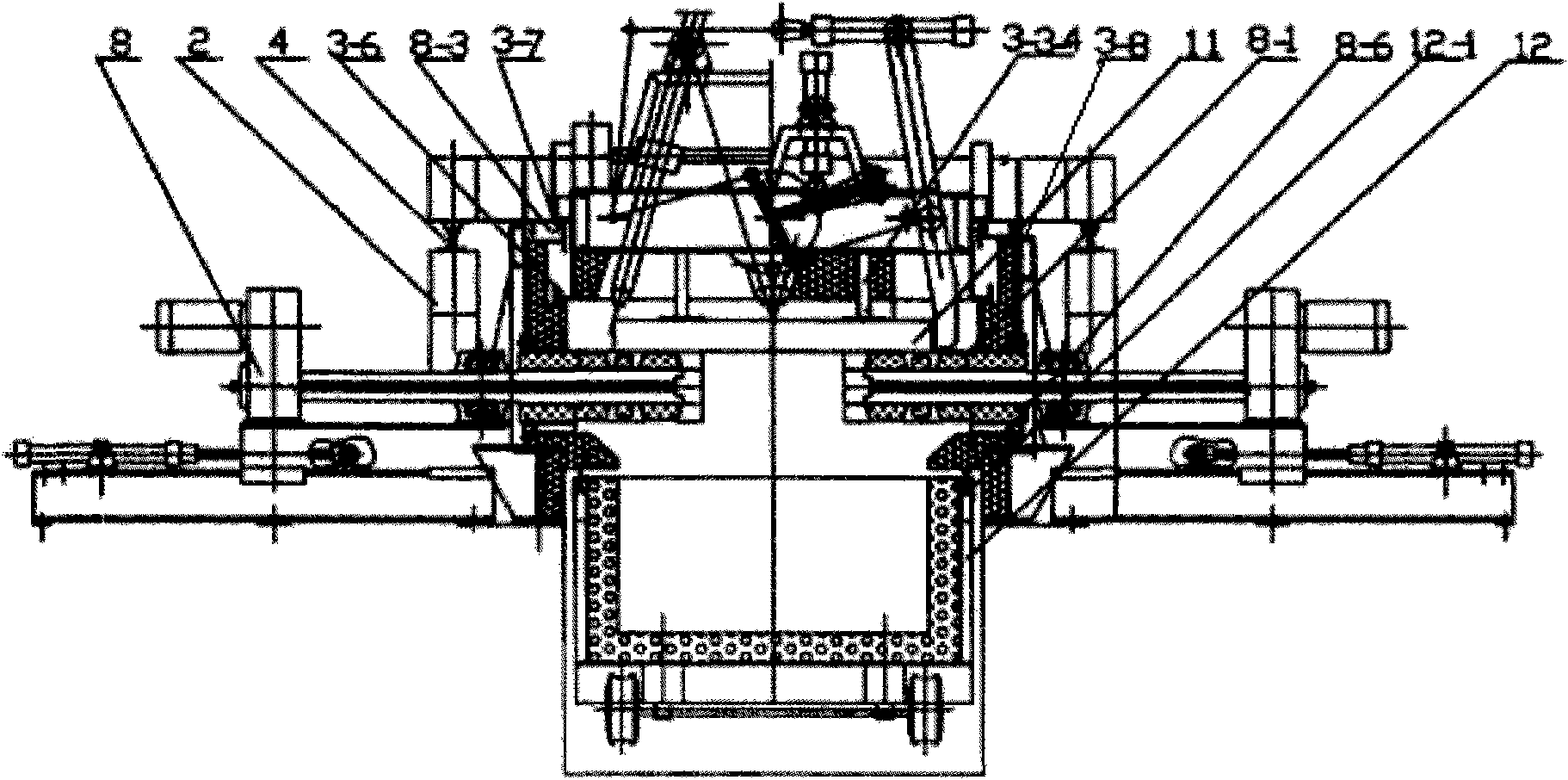

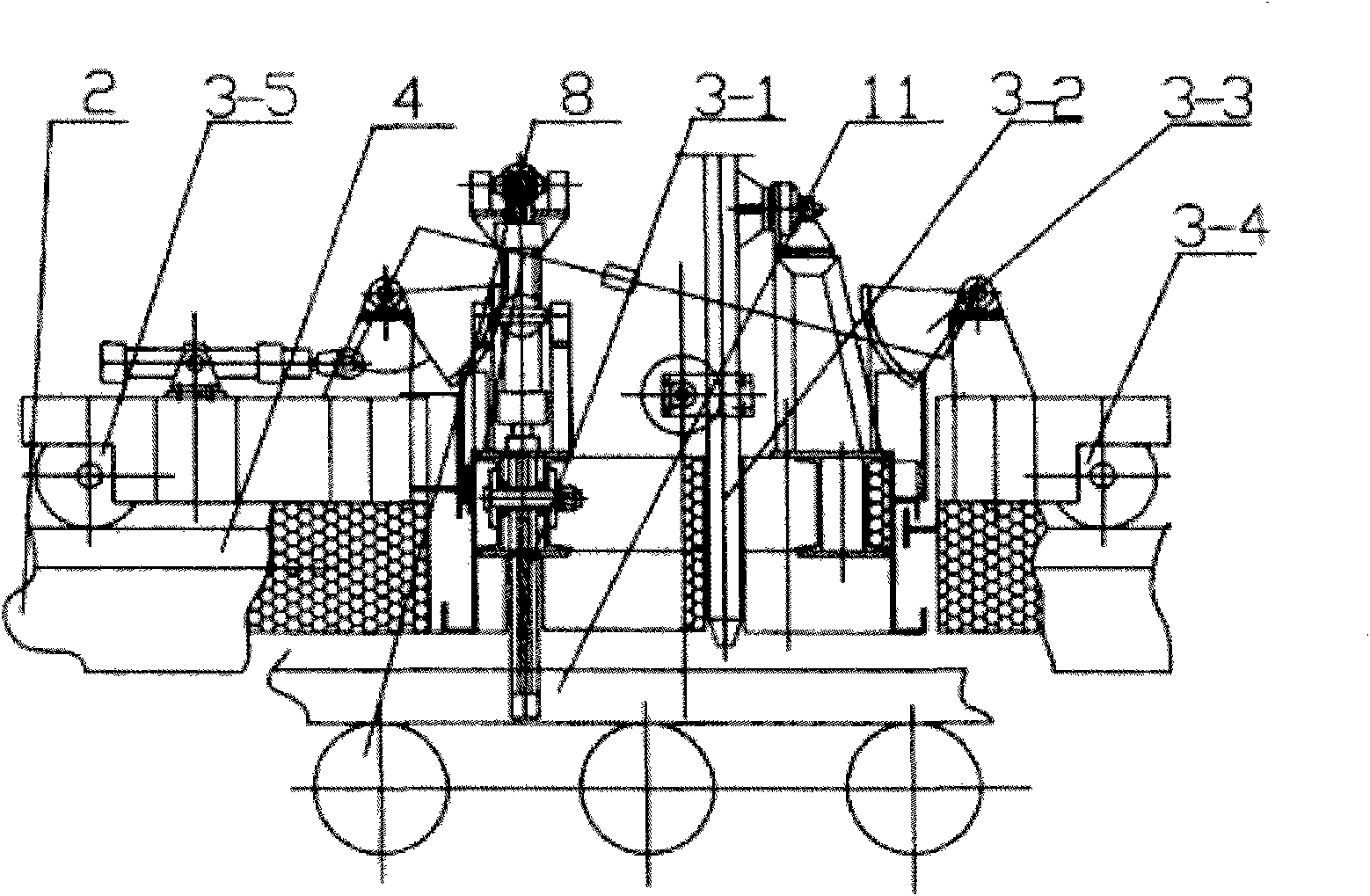

[0035] Such as figure 1 As shown, a flame cutting system for a steel billet flame cutting area with a thermal insulation device provided by the present invention includes track beams 2 located on both sides, and a heavy rail 4 is respectively arranged on the top of each track beam 2, and the flame cutting The car 3 moves back and forth on the heavy rail 4, and at least one mobile heat preservation cover 1 is connected to the front end and the rear end of the flame cutting car 3 respectively, and the mobile heat preservation covers 1 are connected to each other and are on the heavy rail 4 together with the flame cutting car 3 Move back and forth, between the two track beams 2, there is a row of water internally cooled conveying billet roller table 9 and billet cantilever roller table 8 with heat preservation device, the billet 11 located under the flame cutting vehicle 3 is on the billet cantilever roller table 8 front and rear move.

[0036] When the billet 11 detects the len...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com