Internal water-cooling roller way provided with heat insulating device

A technology of heat preservation device and internal water cooling, which is applied in the direction of rolls, lighting and heating equipment, furnace components, etc., can solve the problems of insufficient temperature in the furnace, not fully realized, and oxidation loss, and achieves good stress and operation conditions. , easy to operate, small maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

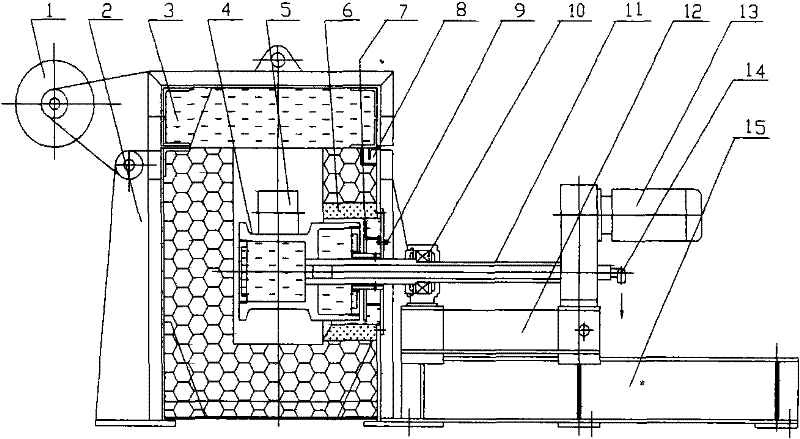

[0034] Such as figure 1 As shown, it is a structural schematic diagram of the first type of internal water cooling single-roller table with heat preservation device. The described water internal cooling single-roller table with heat preservation device The water-cooled roller table unit includes a roller ring 4 made of heat-resistant alloy steel filled with refractory fibers installed in the heat preservation device. There is a hot billet 5 conveyed by the roller ring 4. In the middle of the side wall of the device, at least one end of the roll ring 4 is provided with a prefabricated refractory material 6 on the contact surface with the side wall of the heat preservation device, and the two sides of the roll ring 4 are sealed with cover plates, and the roll ring 4 is welded to the water-cooled shaft 11 , the roller ring 4 and the water-cooled shaft 11 are provided with a shaft seal device 7 on the contact surface with the water-cooled shaft 11. There is a certain gap between i...

Embodiment 2

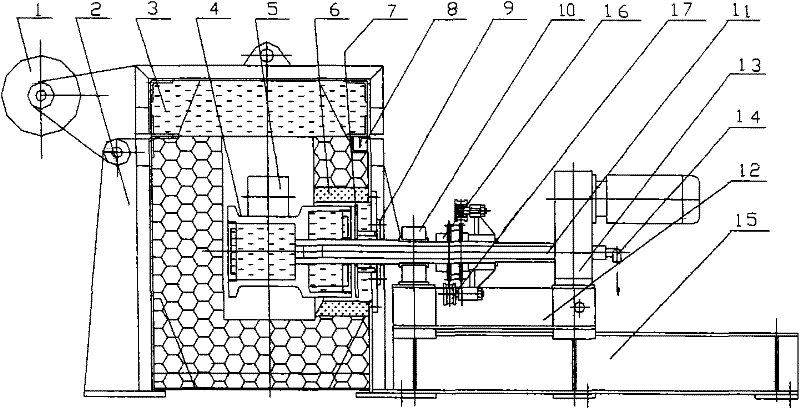

[0037] Such as Figure 4 As shown, it is a schematic diagram of the structure of the second water internal cooling single roller table with a heat preservation device. The difference between it and Embodiment 1 is that the heat preservation device is a walking heating furnace 20, and one end of the roller ring 4 is installed In the middle part of the side wall of the walking heating furnace 20, and connected to the water cooling shaft 11, the roller ring 4 is fixed to the walking heating furnace 20 through the roller guide frame 19, and the bearing housing 10 and the speed reducer 13 are all mounted on the On the mobile support 12, the mobile support 12 is installed on the first roller table base 15.

Embodiment 3

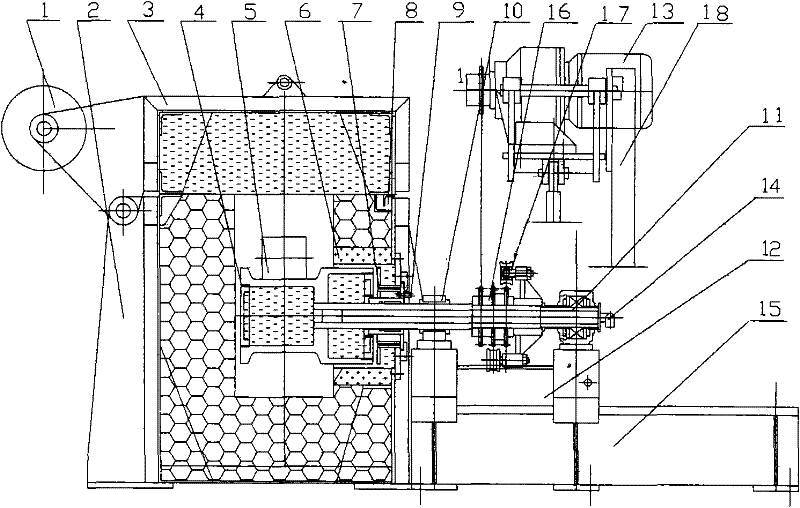

[0039] Such as Figure 5 As shown, it is a schematic diagram of the structure of the third type of water internal cooling single-roller table with a heat preservation device. The difference between it and Embodiment 1 is that the heat preservation device includes a heat preservation box seat 2, and the heat preservation box seat 2 is provided with a filling refractory fiber The second heat preservation cover 3 of the heat preservation box seat 2 is provided with a sand sealing device 8 on the contact surface of the second heat preservation cover 3, and the two ends of the roller ring 4 made of heat-resistant alloy steel are all installed in the middle part of the side wall of the heat preservation box seat 2 , the roller ring 4 is welded to the inner hollow water-cooled shaft 11, the water-cooled shaft 11 is installed in the middle of the roller ring 4, one end of the water-cooled shaft 11 is installed on the bearing housing 10, and the other end of the water-cooled shaft 11 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com