Water internal cooling delivery plate blank roller way with heat preservation device

A heat preservation device and water internal cooling technology, which is applied in the direction of furnaces, lighting and heating equipment, furnace components, etc., can solve problems such as easy cracks, low casting speed, and long cutting time, so as to prolong the service life and prevent damage. Roller table, solve the effect of shaft end seal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

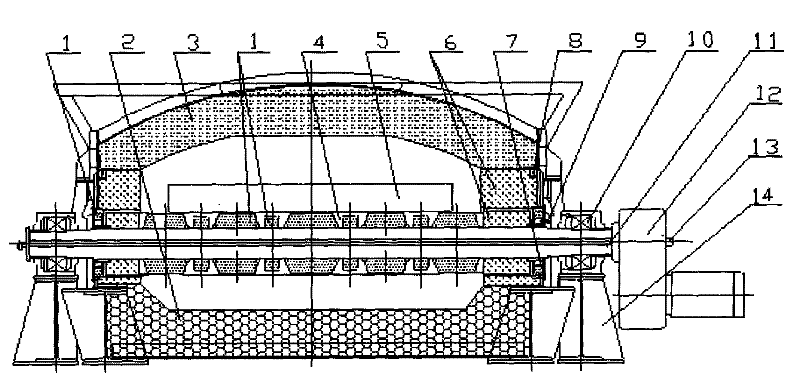

[0030] Such as figure 1 As shown, the water internally cooled conveying slab roller table of a kind of heat preservation device provided by the present invention includes refractory fiber 1 filled in heat-resistant alloy steel (refractory fiber is filled with ceramic fiber or refractory castable) located in the heat preservation device , the roll ring 4 (available lcr25ni20si2 steel plate, the same below) can be made of lygx-421 from Luyang or the heat-resistant castable for hearth rolls developed by Madashan Iron and Steel Company, the same below), and the roll ring 4 is made of its The hot blank 5 transported, the roller ring 4 is arranged in the heat preservation box, and the first ceramic fiber special-shaped part 6 (lygx-355 available from Luyang) is provided on the contact surface of at least one end of the roller ring 4 and the side wall of the heat preservation device. , the same below), the roll ring 4 is welded to the water-cooled shaft 11, and the first shaft seal ...

Embodiment 2

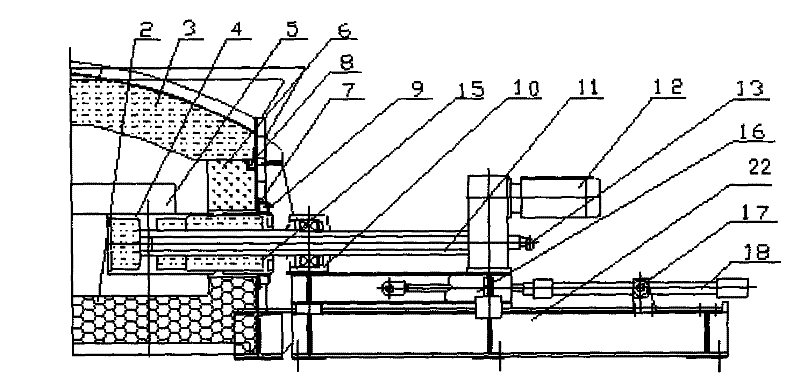

[0033] Such as figure 2As shown, it is a schematic diagram of the cantilever roller table unit of the water internal cooling conveying slab with the heat preservation device. Connected, a garden ring 15 made of heat-resistant ductile iron (RQTSi-5.5, the same below) is set in the first shaft seal device 7, which is conducive to the leakage prevention of the shaft seal, and is separated from the roller ring 4 by a certain distance to reduce heat transfer. The bearing block 10 and the reducer 12 with frequency conversion motor are all installed on the mobile bracket 16, and the mobile bracket 16 is installed on the second roller table base 22, and the second roller table base 22 is equipped with a swing hydraulic cylinder 18, and the pushing force of the hydraulic cylinder 18 The garbage bar is connected on the mobile bracket 16, and the support 17 of the swing hydraulic cylinder 18 is installed on the second roller table base 22. When the flame cutting nozzle approaches the ca...

Embodiment 3

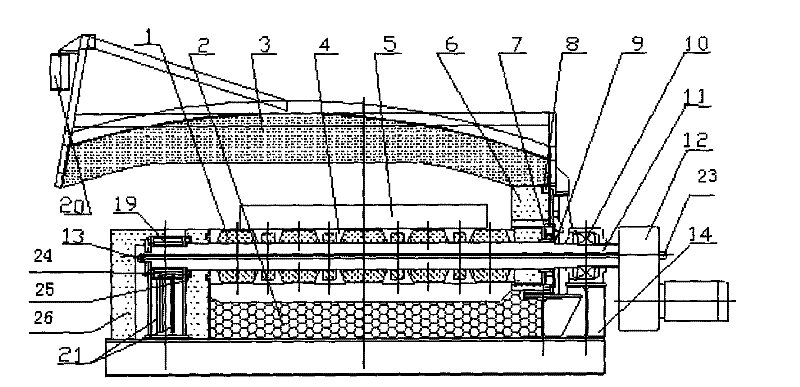

[0035] Such as image 3 As shown, the difference between this embodiment and Embodiment 1 is that the other end of the water-cooled shaft 11 is installed in the high-temperature oil-impregnated bearing and bearing seat 19 located in the heat-retaining cover 3, and the high-temperature oil-impregnated bearing and A water-cooling device is provided outside the bearing housing 19, and a second shaft seal device 24 is provided on the side of the high-temperature oil-impregnated bearing and the bearing housing 19. The outside is provided with a second ceramic fiber special-shaped part 26 for heat insulation, and the high-temperature oil-impregnated bearing and the bearing seat 19, the bearing seat 10 and the speed reducer 12 with the frequency conversion motor are all installed on the third roller table base 23.

[0036] The air inlet 9 in the first shaft sealing device 7, the second air inlet 25 on the second shaft sealing device 24 and the water inlet and outlet pipe 21 outside t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com