Switching type descaling bubbler and faucet

A switchable bubbler technology, which is applied in construction, water supply equipment, indoor sanitary pipeline installations, etc., can solve the problems of stubborn dirt washing away, inconvenient cleaning of the bubbler, and poor cleaning effect, etc., to reduce The probability of clogging, the novel method of descaling, and the effects of various water outlet modes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

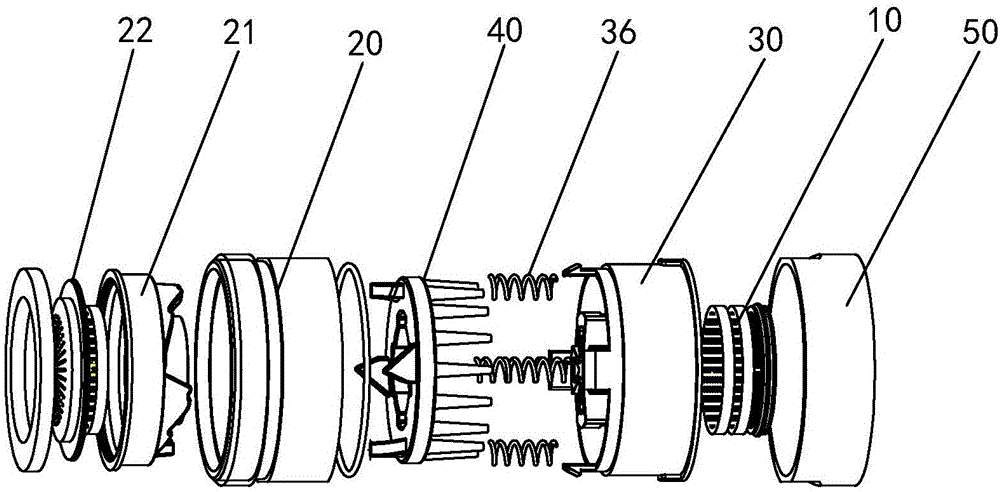

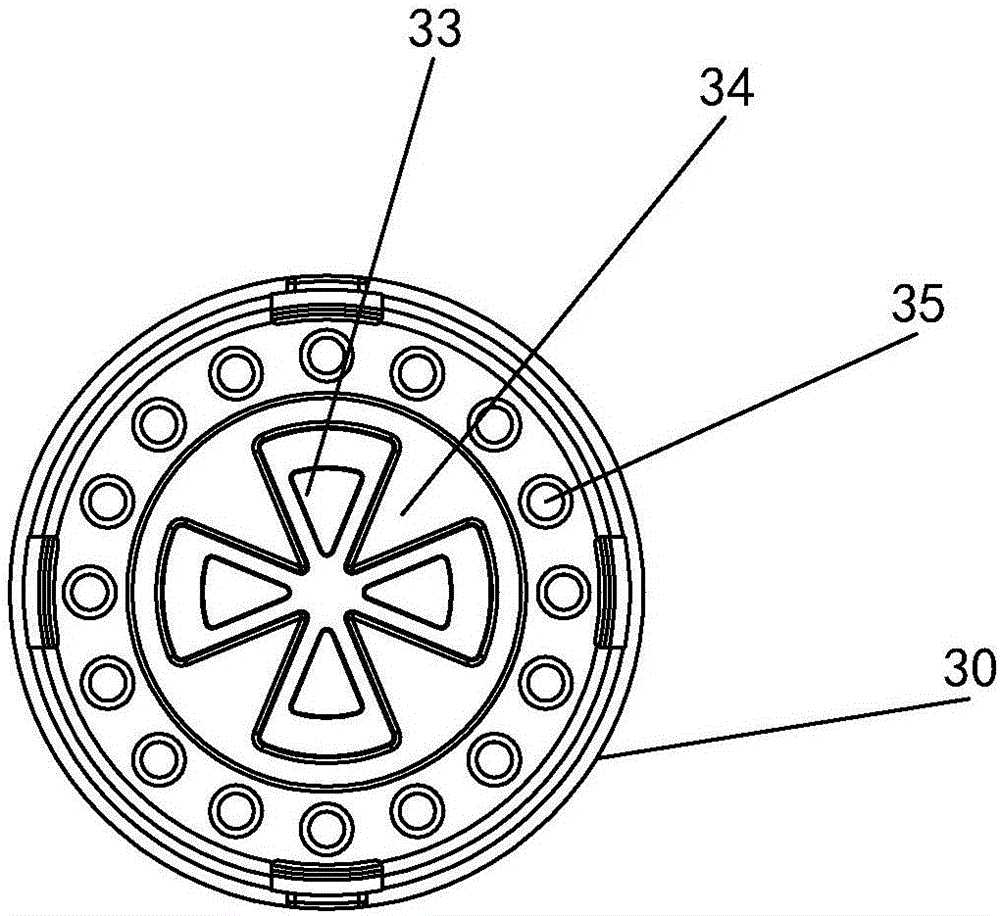

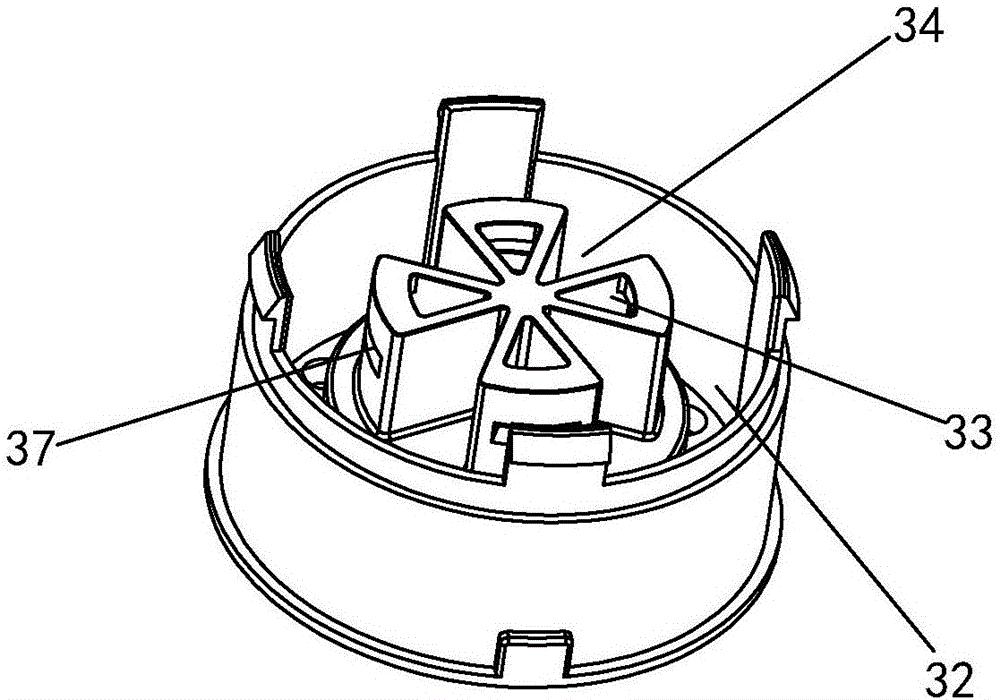

[0049] refer to Figure 1 to Figure 15, a switchable descaling foamer, including a foaming assembly 10, a fixed sleeve 20, a moving core 30 and a descaling member 40. The top of the fixing sleeve 20 is provided with a fixed inner core 21 and a filter device 22, and the filter device 22 is fixed on the water inlet side of the fixed inner core 21 through a rubber pad. The middle part of the fixed inner core 21 is provided with several through water inlets 23 , and the bottom of the fixed inner core 21 is provided with a number of slope blocks 24 distributed along the circumference, and the slope blocks 24 are distributed around the water inlets 23 . Each ramp block 24 is provided with a first water outlet gear groove 25, a second water outlet gear groove 26 and a descaling gear groove 27, the descaling gear groove 27 is at the highest point, and the first water outlet gear groove 25 is located At the lowest point, the second water outlet gear slot 26 is located between the two....

Embodiment 2

[0061] refer to Figure 16 to Figure 18 , a switchable descaling bubbler and a faucet, the main features of which are the same as those in Embodiment 1, the difference being that the fixing sleeve 20 is not provided with a filtering device. The water inlet 23 of the fixed inner core 20 is provided with a descaling pad 23a, and the first water inlet hole 33 of the first water outlet channel 31 of the movable inner core 30 is provided with a filter screen 38 as a filtering device.

[0062] refer to Figure 19 - Figure 2 1. The water outlet principle is the same as that of Embodiment 1, the difference is that when the rotating sleeve 50 is controlled to rotate, the moving inner core 30 rotates, and when the filter 38 wipes the descaling pad 23a, the filter 38 can be cleaned. Descaling, so that both the first water outlet channel 31 and the second water outlet channel 32 are descaled.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com