Distillation tank

A tank body and tank cover technology, applied in the field of distillation tanks, can solve the problems of impure distillate, inconvenient cleaning, easy fouling of coils, etc., and achieve the effect of simple and convenient cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Describe in further detail below in conjunction with accompanying drawing and embodiment of the present invention:

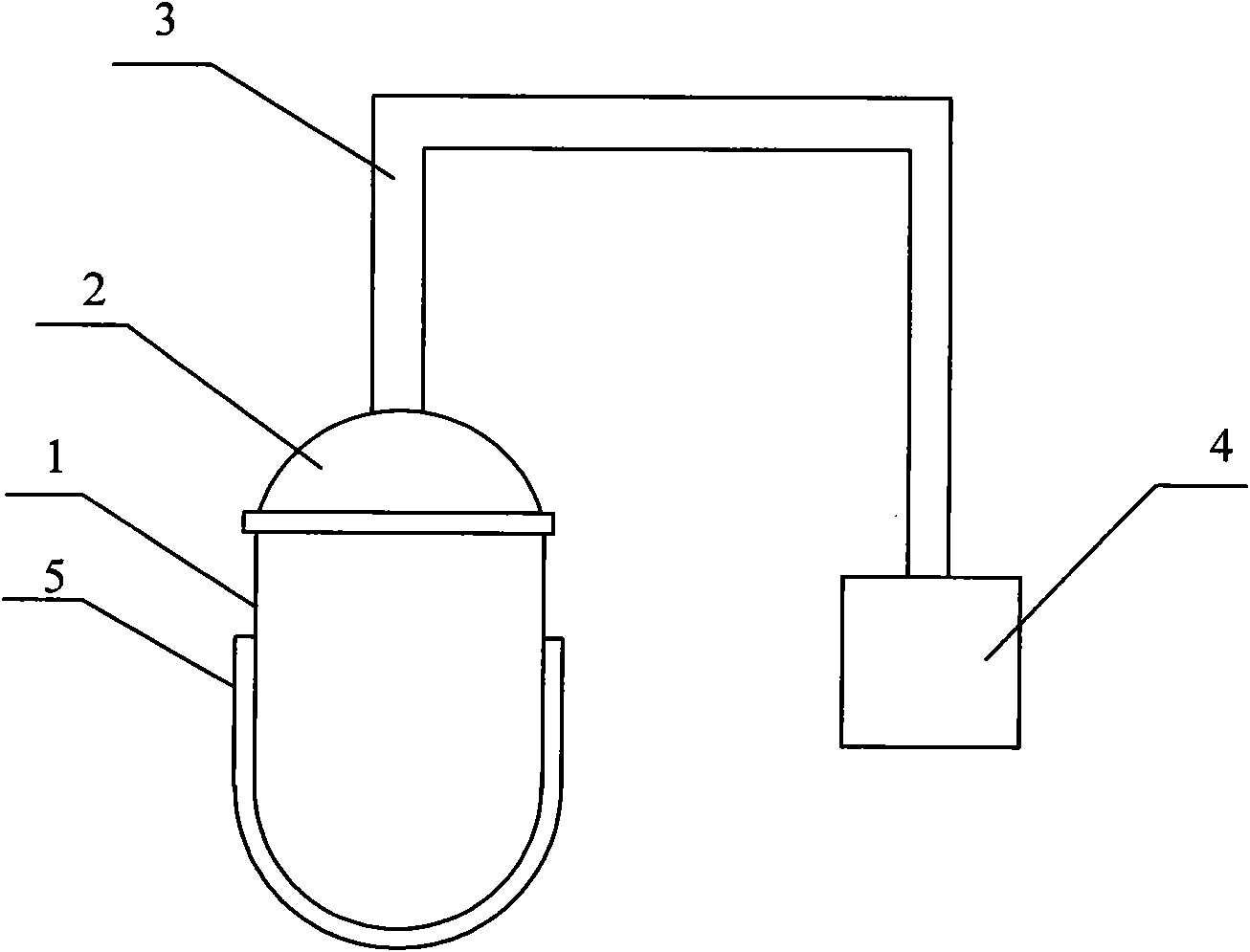

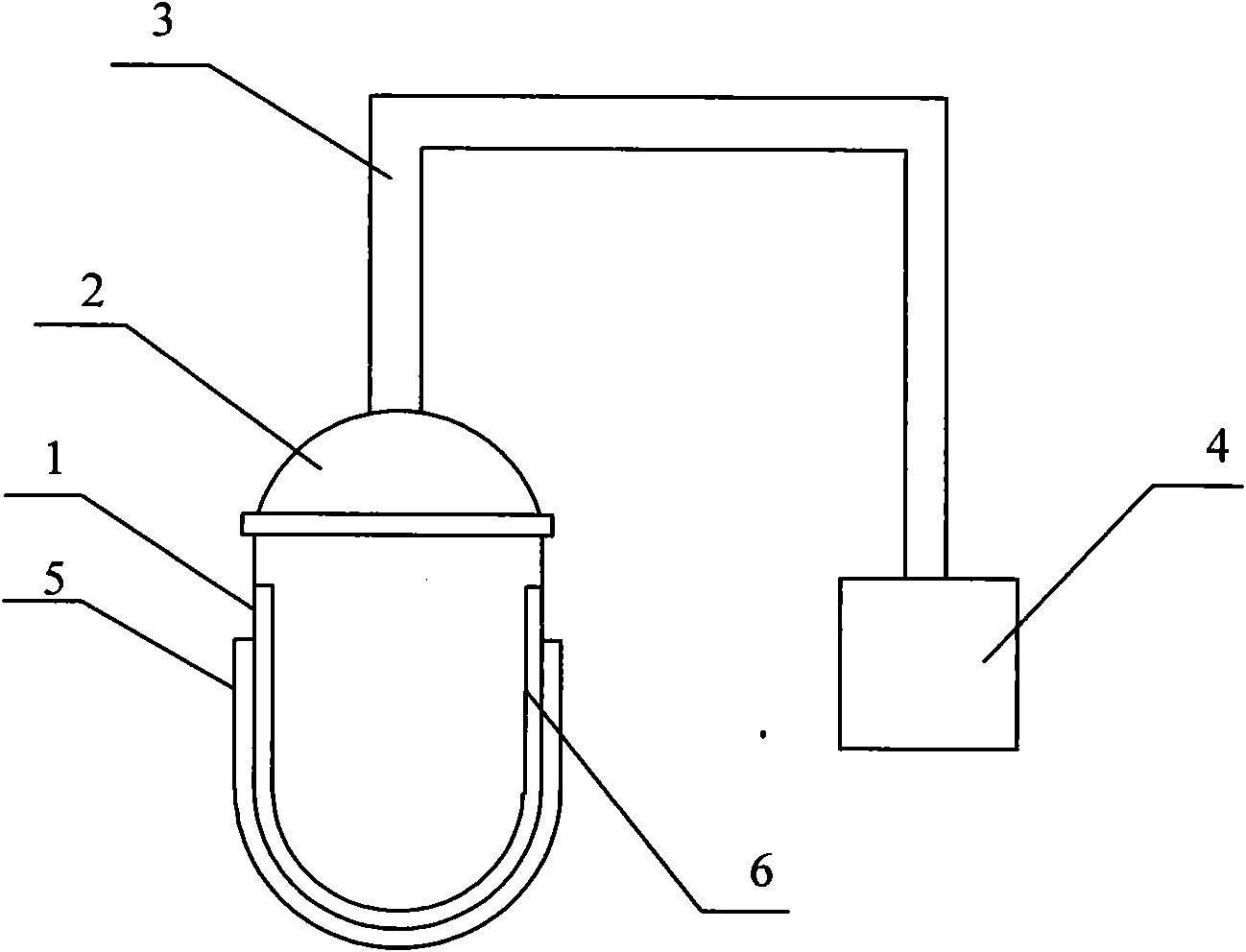

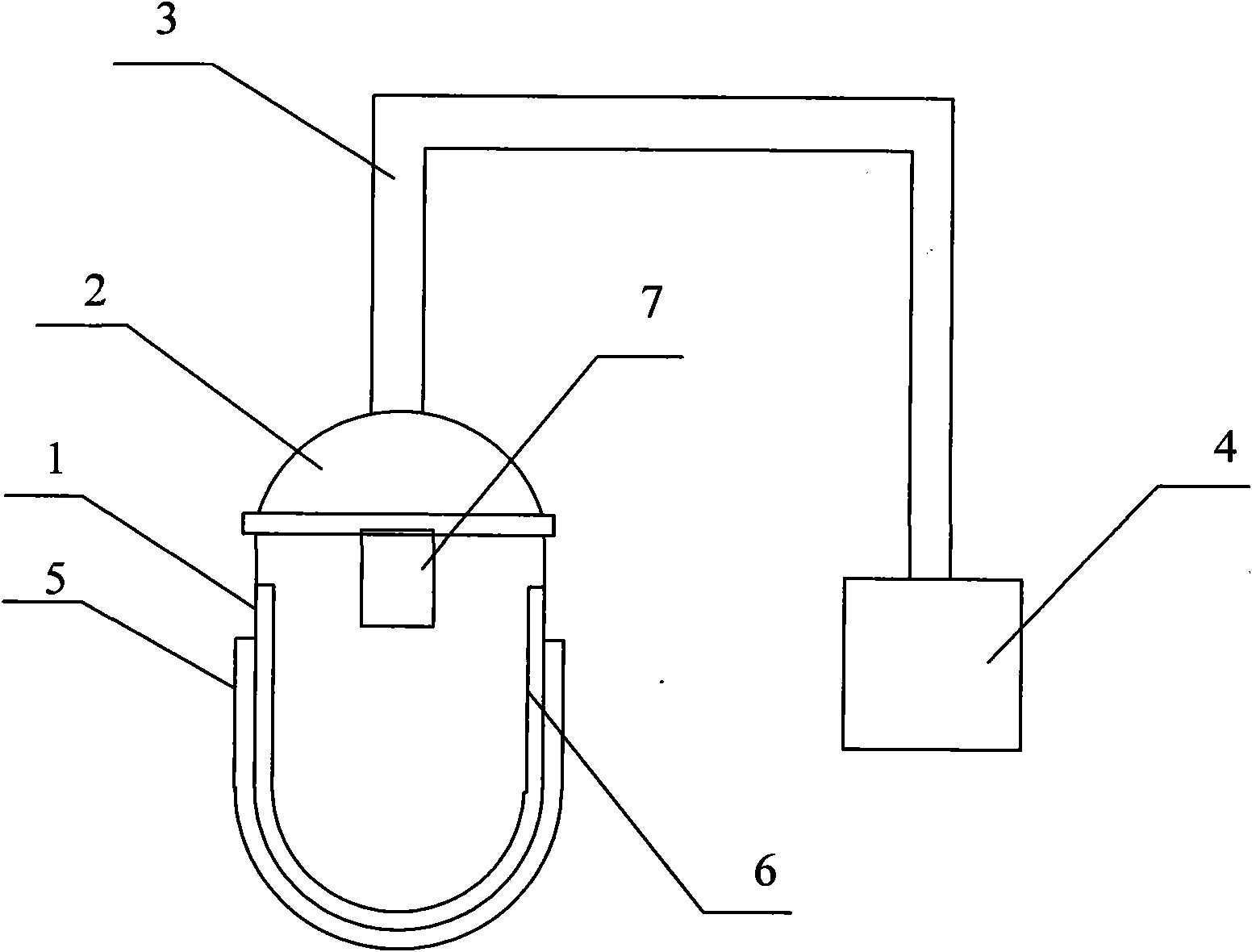

[0014] figure 1 A first embodiment of the invention is shown. Such as figure 1 As shown, the distillation tank of the present invention includes a tank body 1 and a tank cover 2. The tank cover 2 covers the tank body 1, and the inside of the whole distillation tank is in a sealed and vacuum state by means of sealing. The bottom of the tank body is set as a hollow heating interlayer 5, which is filled with heat transfer oil. By heating the heat transfer oil, the waste liquid in the distillation tank is indirectly heated. The waste liquid contains impurities, dirt, iron powder, etc. The waste liquid in the distillation tank body 1 is heated by the heat medium heat transfer oil in the distillation tank to make the distillate boil and gasify to form a distillate, which is transported to the condensation pump 4 through the delivery pipe 3 . One end of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com