Passive descaling type evaporative cooler

An evaporative cooler and evaporative cooling technology, which is used in the cleaning of rotating equipment, cleaning heat transfer devices, lighting and heating equipment, etc. The effect of spark contact with gas, safe descaling operation, avoidance of explosion hazard

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

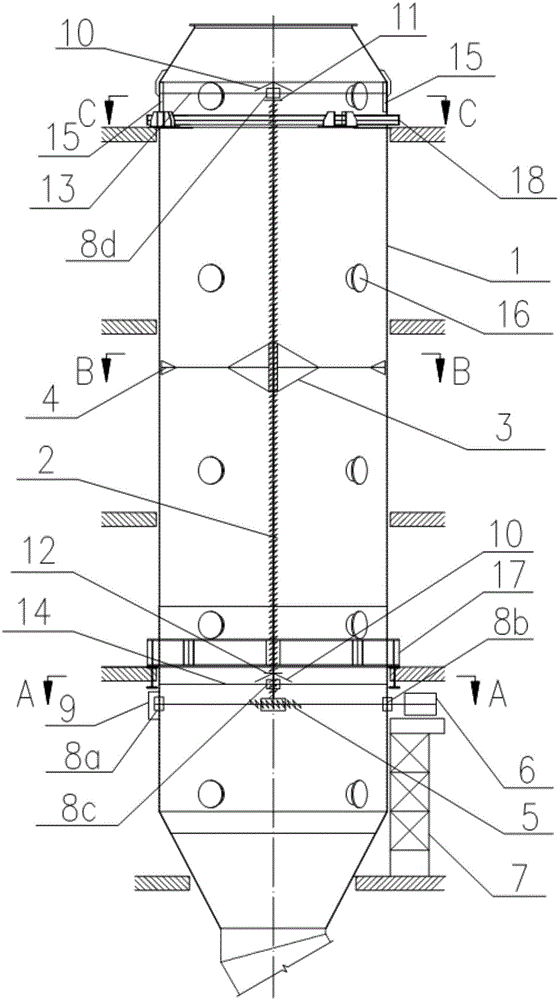

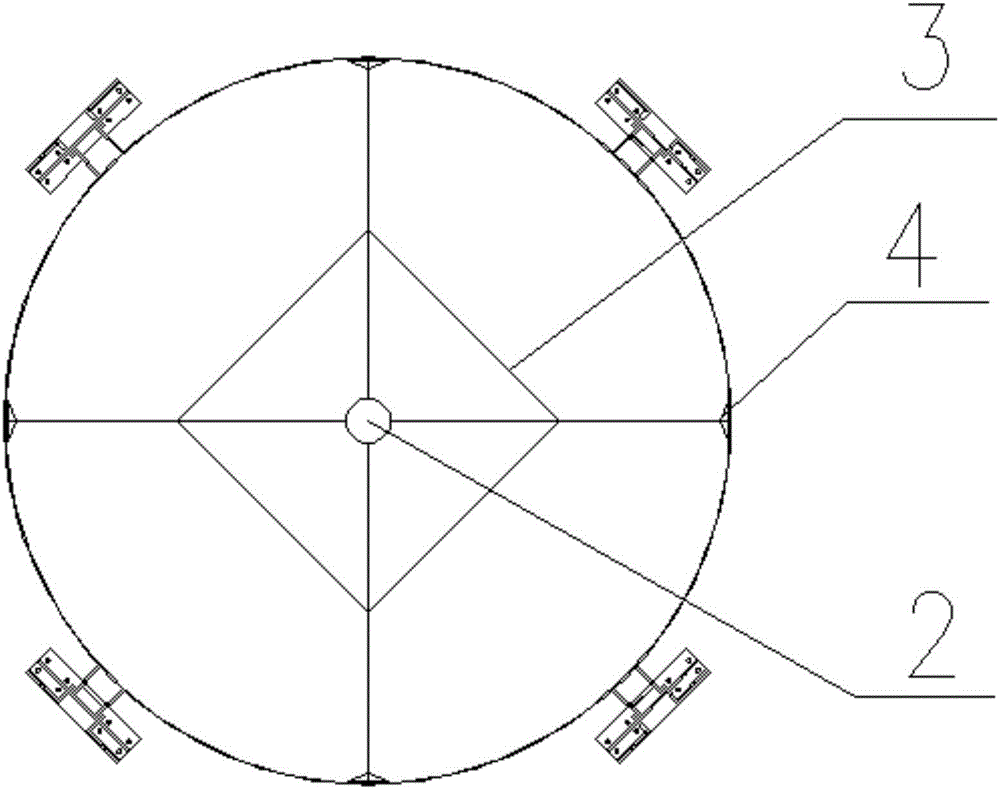

[0061] like Figure 5 As shown, the descaling device includes a knife support frame 3 and a descaling knife 4, the descaling knife 4 is installed on the support mechanism 2 through the knife support frame 3, the descaling knife 4 is arranged along the axial direction of the evaporative cooling cylinder 1, and the descaling The length of the cutting edge of the knife 4 matches the length of the evaporative cooling cylinder 1, and the driving mechanism 6 drives the descaling device to rotate along the circumferential direction of the evaporative cooling cylinder 1 for descaling. The knife support frame 3 is fixedly connected with the support mechanism 2, and the descaling knife 4 is installed on the peripheral end of the knife support frame 3. The knife support frame 3 adopts a frame structure, and the number of descaling knives 4 is along the evaporative cooling cylinder 1 according to requirements. Arranged in the circumferential direction, the support mechanism 2 drives the k...

Embodiment 3

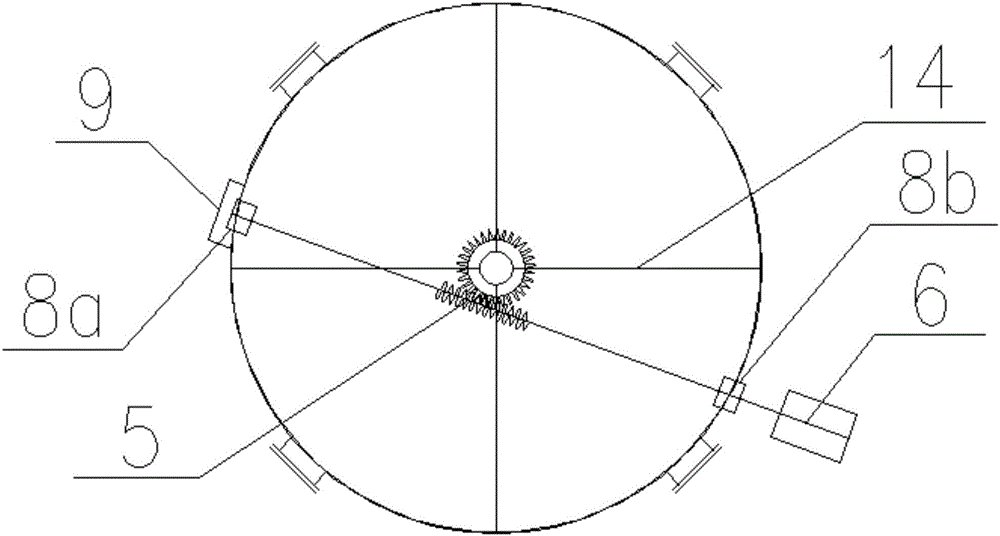

[0063] like Image 6 and Figure 7 As shown, the descaling device includes a knife support frame 3 and a descaling knife 4. The descaling knife 4 is installed on the support mechanism 2 through the knife support frame 3. The descaling knife 4 is arranged along the circumference of the inner wall of the evaporative cooling cylinder 1, and at least Covering its inner circumference, that is, the circumferential circle of the knife support frame 3 is covered with descaling knives, and the cutting edge of the descaling knife is arranged in a circle, so that the descaling knife is in full contact with the inner wall of the evaporative cooling cylinder 1 in the circumferential direction, The descaling knife 4 on the knife support frame 3 is provided with at least one circle, and the number of circles of the descaling knife 4 can be adjusted as required. The driving mechanism 6 drives the descaling device to move along the axial direction of the evaporative cooling cylinder 1 for des...

Embodiment 1

[0064] The operating steps of embodiment one and embodiment three are:

[0065] 1) Before the converter oxygen blowing starts, the knife support frame 3 stops at the limit device 12 at the lower end of the support mechanism 2;

[0066] 2) After the converter starts tapping, the drive mechanism 6 runs, the support mechanism 2 drives the knife support frame 3 to rotate from bottom to top through the screw drive, and the descaling knife 4 at the end of the knife support frame 3 scrapes off the inner wall of the evaporative cooling cylinder 1 Dust, the knife support frame 3 moves upward until the upper limit device 11 of the support mechanism 2 . Then the drive mechanism 6 reverses, driving the knife support frame 3 to rotate from top to bottom.

[0067] 3) Before the oxygen blowing of the converter starts, the knife support frame 3 rotates back to the starting position, that is, stops at the limit device 12, and completes one descaling, one descaling for each furnace of steel, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com