Oil conservator for sleeve and processing technology of oil conservator

A technology of oil conservator and bushing, which is applied in the direction of electrical components, transformer/inductor parts, circuits, etc. It can solve the problems of unsatisfactory sealing performance, inability to observe oil level changes, and poor stability of pressing parts, etc., to ensure that Excellent sealing performance, convenient installation and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

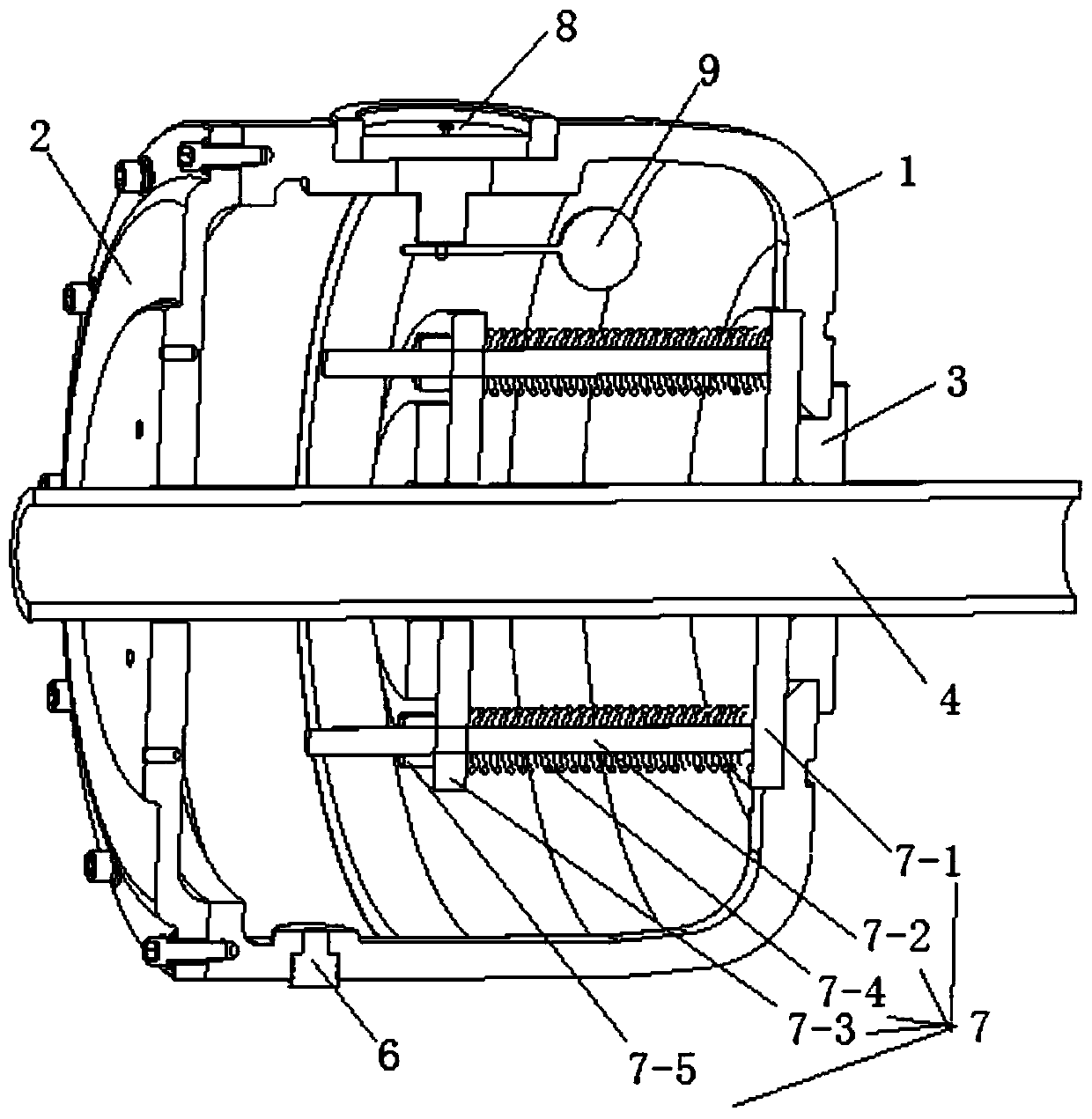

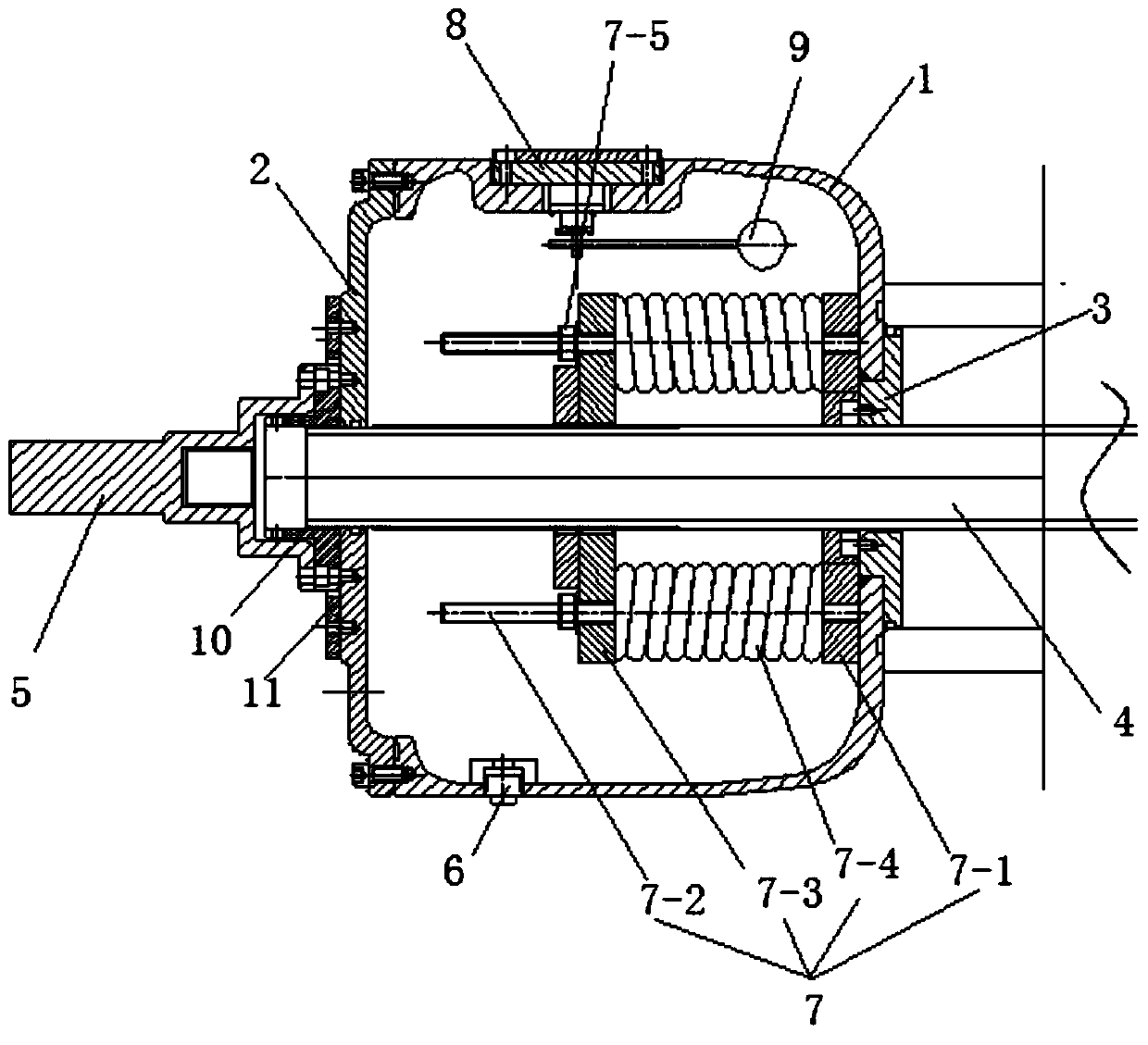

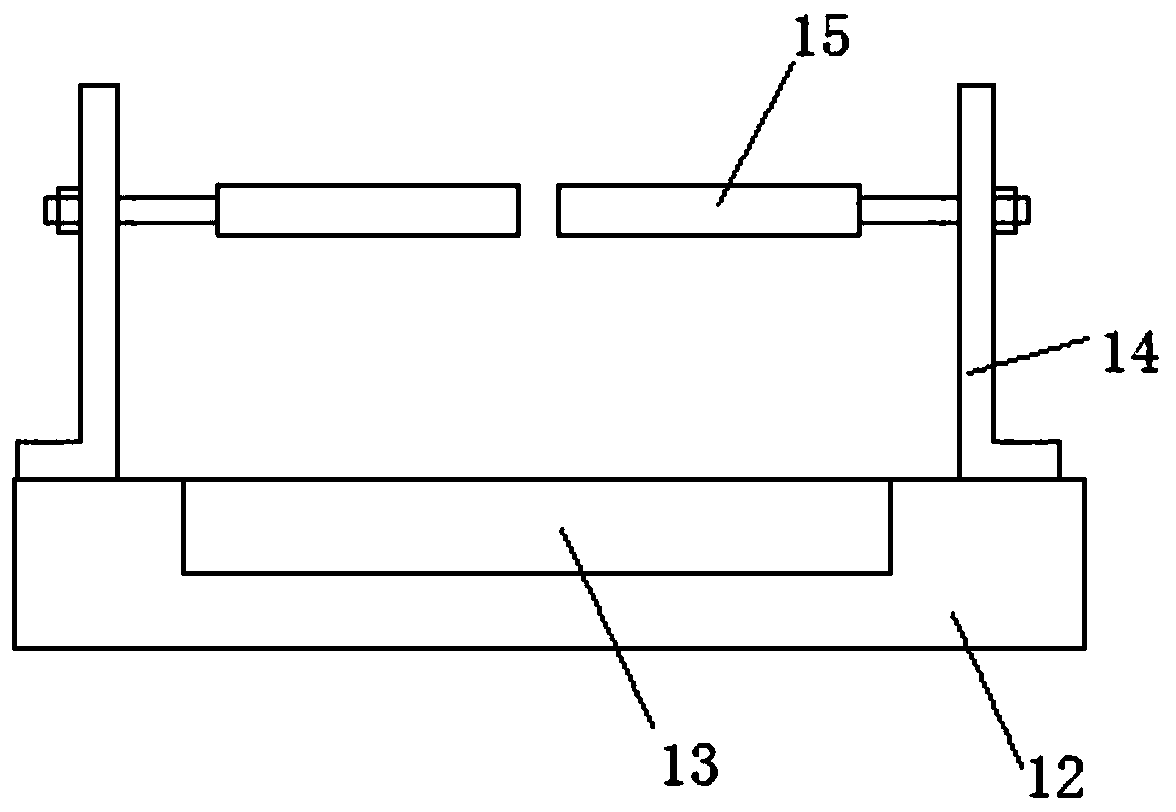

[0024] See attached picture.

[0025] An oil conservator for casing, comprising an oil conservator main body 1, which is a hollow cylindrical structure, an oil conservator cover plate 2 is installed on one end of the oil conservator main body 1, and a rear end is installed on the other end of the oil conservator main body 1 The sealing plate 3, the middle part of the rear end sealing plate 3 and the middle part of the oil conservator cover plate 2 are respectively provided with installation holes, and a copper pipe 4 for conducting electricity is installed in the installation hole, and the front end of the copper pipe 4 protrudes from the end of the oil conservator cover plate 2 In addition, the oil conservator cover plate 2 is equipped with a conductive head 5 matched with the copper pipe, and the rear end of the copper pipe 4 and the oil conservator main body 1 are sealed by the rear end sealing plate 3. A spring compression mechanism 7 for auxiliary pressure sealing is inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com