Preparation method of CeO2/gamma-Al2O3 multi-level structure composite microspheres

A composite microsphere, hierarchical structure technology, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve problems such as regulation and control without structure and morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 1. Dissolve potassium aluminum sulfate and ceric sulfate in deionized water to make the concentrations 0.04mol / L and 4mmol / L respectively, then add urea to make the concentration 0.2mol / L under stirring at room temperature, and continue stirring for 10 minutes to make them completely Dissolve to ensure that the reactants are mixed evenly;

[0020] 2. Transfer the above mixed solution to a stainless steel reaction kettle lined with polytetrafluoroethylene, seal it, react at 180°C for 5 hours, and cool it down to room temperature naturally;

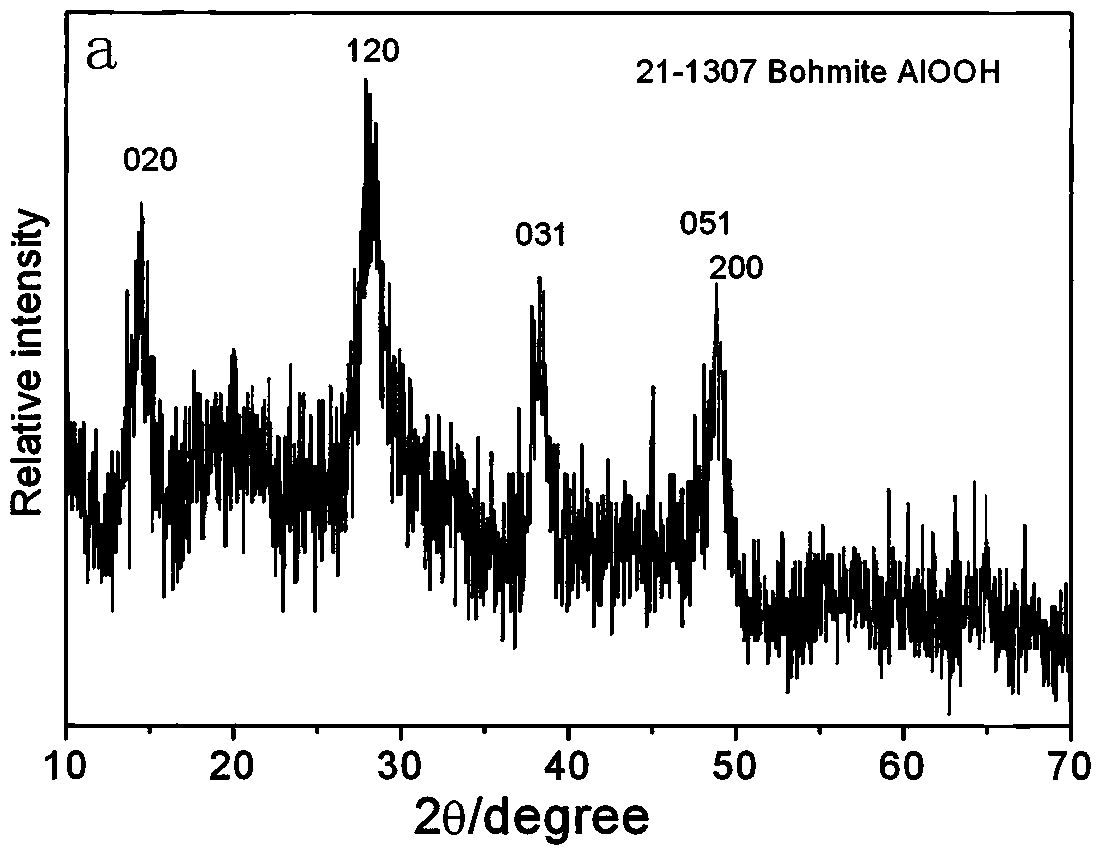

[0021] 3. Centrifuge the above reaction mixture at 3000r / min for 5min, pour off the supernatant, wash the obtained precipitate repeatedly with water and ethanol, and then dry it in a 60°C drying oven to obtain the precursor CeO 2 / AlOOH composite microspheres;

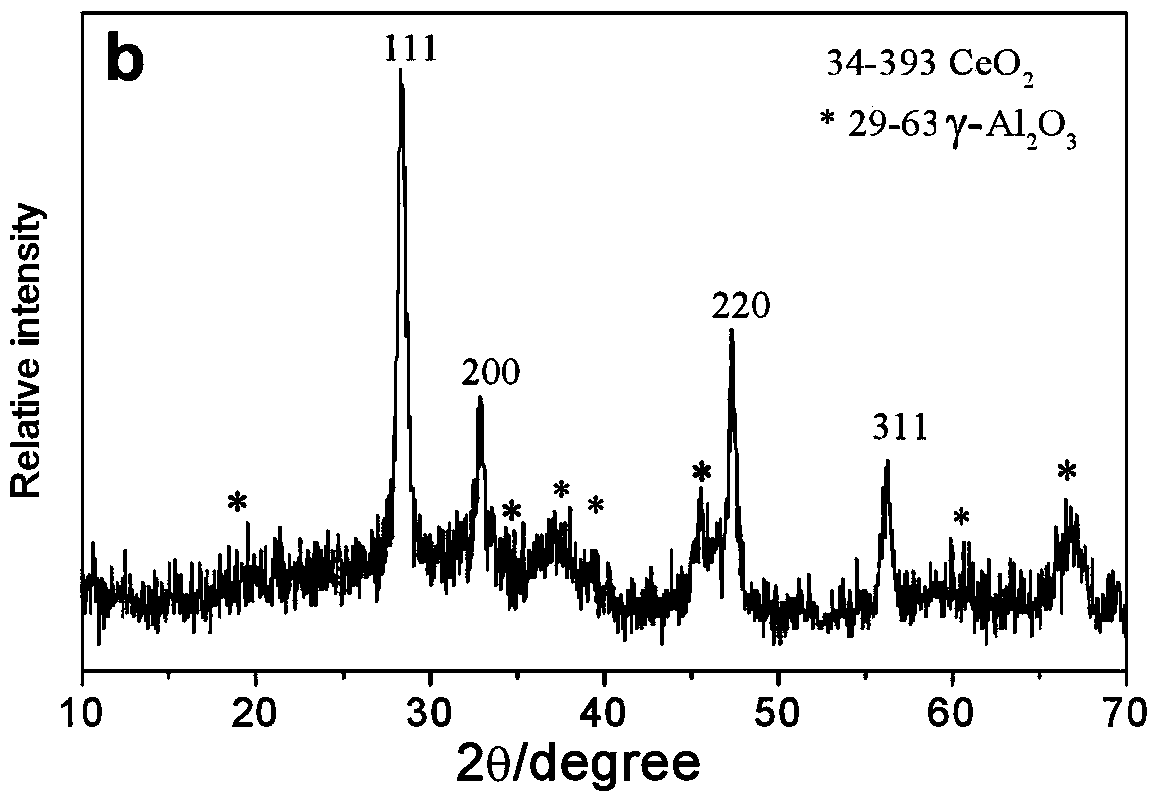

[0022] 4. Put the dried precursor microspheres into the muffle furnace, raise the temperature to 800°C at a rate of 1°C / min, and keep it for 1h to obtain CeO 2 / γ-Al 2 o ...

Embodiment 2

[0024]1. Dissolve aluminum potassium sulfate and ceric sulfate in deionized water to make the concentrations 0.04mol / L and 6mmol / L respectively, then add urea under stirring at room temperature to make the concentration 0.2mol / L, and continue to stir for 10 minutes to make them completely Dissolve to ensure that the reactants are mixed evenly;

[0025] 2. Transfer the above mixed solution to a stainless steel reaction kettle lined with polytetrafluoroethylene, seal it, react at 180°C for 5 hours, and cool it down to room temperature naturally;

[0026] 3. Centrifuge the above reaction mixture at 3000r / min for 5min, pour off the supernatant, wash the obtained precipitate repeatedly with water and ethanol, and then dry it in a 60°C drying oven to obtain the precursor CeO 2 / AlOOH composite microspheres;

[0027] 4. Put the dried precursor microspheres into the muffle furnace, raise the temperature to 700°C at a rate of 1°C / min, and keep it for 1h to obtain CeO 2 / γ-Al 2 o 3 ...

Embodiment 3

[0029] 1. Dissolve aluminum potassium sulfate and ceric sulfate in deionized water to make the concentrations 0.04mol / L and 4mmol / L respectively, then add urea under stirring at room temperature to make the concentration 0.4mol / L, and continue to stir for 10 minutes to make them completely Dissolve to ensure that the reactants are mixed evenly;

[0030] 2. Transfer the above mixed solution to a stainless steel reaction kettle lined with polytetrafluoroethylene, seal it, react at 180°C for 5 hours, and cool it down to room temperature naturally;

[0031] 3. Centrifuge the above reaction mixture at 3000r / min for 5min, pour off the supernatant, wash the obtained precipitate repeatedly with water and ethanol, and then dry it in a 60°C drying oven to obtain the precursor CeO 2 / AlOOH composite microspheres;

[0032] 4. Put the dried precursor microspheres into the muffle furnace, raise the temperature to 600 °C at a rate of 1 °C / min, and keep it for 2 hours to obtain CeO 2 / γ-Al ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com