Method for increasing fucoxanthin content of Phaeodactylum tricornutum by using ammonium ceric sulfate

A technology of Phaeodactylum fucoxanthin and ammonium cerium sulfate, which is applied in the field of biomedicine to achieve the effect of increasing the content, increasing the content and reducing the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

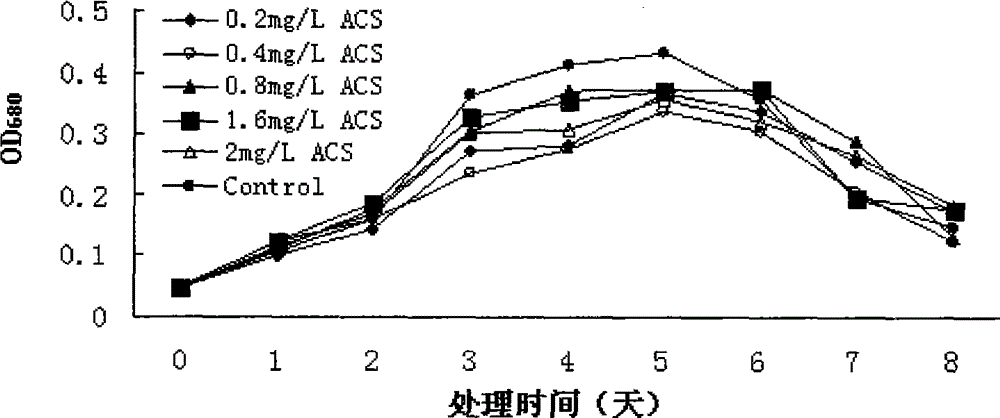

[0036] Embodiment 1 The influence of ammonium cerium sulfate on fucoxanthin in Phaeodactylum tricornutum

[0037] Take 18 groups of 300ml sterilized MAD culture solution, respectively, and insert them into Phaeodactylum tricornutum algae at a ratio of 1:10. Use 0.2mg / L, 0.4mg / L, 0.8mg / L, 1.6mg / L, 2mg / L ammonium cerium sulfate to treat Phaeodactylum tricornutum and 3 parallel groups without any treatment. From the day when Phaeodactylum tricornutum was inserted into the culture medium, the concentration of each group of algae liquid was measured by spectrophotometer every day, and then measured for another 6 days.

[0038] The result is as figure 1 As shown, when different concentrations of cerium ammonium sulfate (CAS) were added, the absorbance value of each group did not change significantly. The OD value of algae treated with L ammonium cerium sulfate was the smallest. Wherein the OD value of the control group was 0.4322, and the OD value of the 0.4mg / L experimental grou...

Embodiment 2

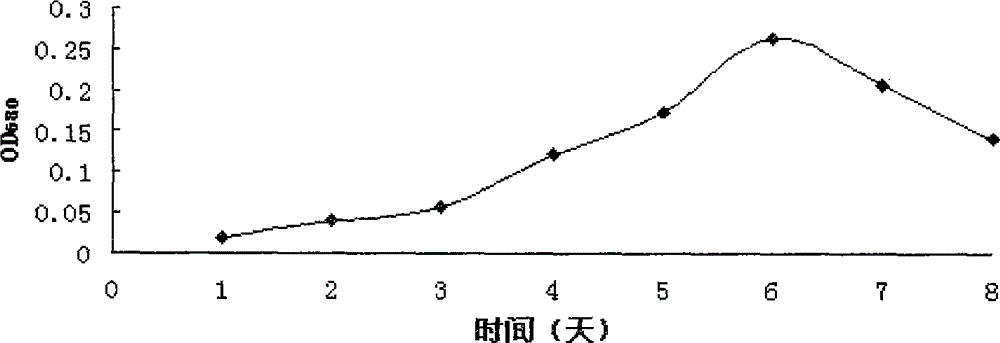

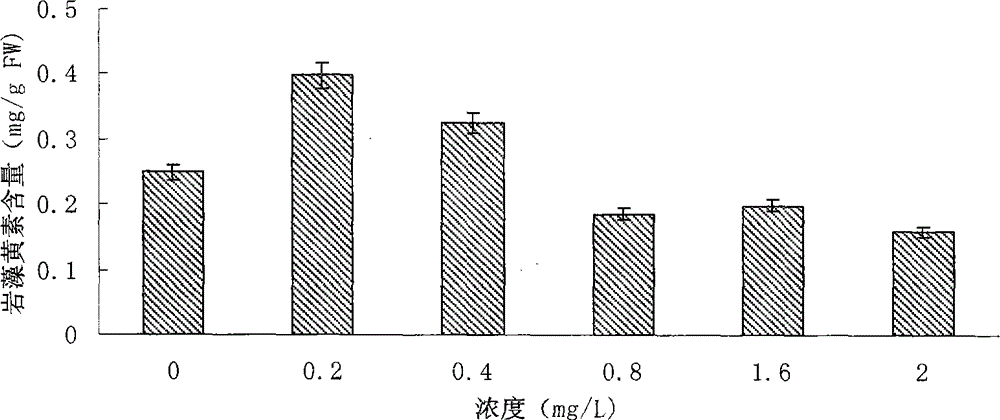

[0040] Take 400ml of sterilized seawater for 7 groups, and add 400μl of MAD mother solution respectively. Add 40ml of Phaeodactylum tricornutum mother solution to the culture solution and cultivate in a light incubator. After 2 days of cultivation, different concentrations of ammonium cerium sulfate were added to the 6 groups of algae culture solutions, the concentrations were 0mg / L, 0.2mg / L, 0.4mg / L, 0.8mg / L, 1.6mg / L, 2.0mg / L, respectively. mg / L.

[0041] Such as figure 2 As shown, from the determination of the growth curve of Phaeodactylum tricornutum, it can be known that Phaeodactylum tricornutum has reached the end of the logarithmic phase after culturing to the 6th day, and the maximum biomass can be obtained. Therefore, it is necessary to collect the algae liquid when cultivating to the 6th day.

[0042]Take 80ml of each group of Phaeodactylum tricornutum into a centrifuge tube, centrifuge at 4°C, 5000rpm for 10min, discard the supernatant, take 1ml of MAD seawater ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com