L-tartaric acid ceric sulfate ferroelectric functional material and preparation method thereof

A ferroelectric functional material, tartaric acid technology, applied in the direction of polycrystalline material growth, chemical instruments and methods, single crystal growth, etc., to achieve high yield, low equipment requirements, simple and easy process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Add 2mmol (0.34g) of CeO to a polytetrafluoroethylene-lined stainless steel reactor 2 , 4mmol (0.60g) of L-(+)-tar, and then dropwise added 2mL of sulfuric acid solution with a concentration of 1mol / L to mix, then added 16mL of deionized water, stirred evenly, and sealed; Thermal reaction for 5 days, the hydrothermal reaction equation is as follows:

[0021]

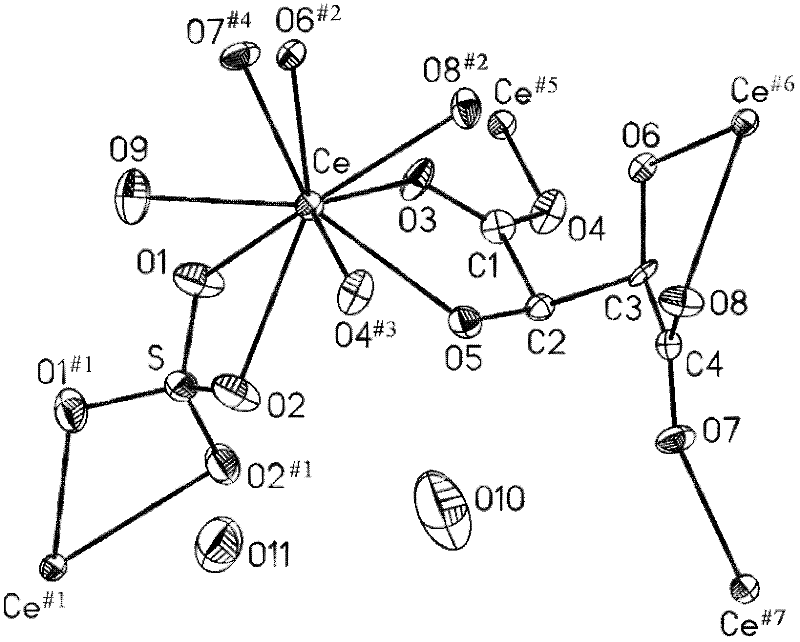

[0022] In this way, through hydrothermal synthesis, the hydrolysis reaction is intensified, the oxidation-reduction potential of the substance is significantly changed, and the reaction is accelerated; L-cerium sulfate flaky crystal of tartrate; Grind the flaky crystal of cerium sulfate L-tartrate, sieve it with 100 mesh sieve, and obtain white cerium sulfate L-tartrate monoclinic crystal with a purity of not less than 99% through 100 mesh sieve It is a powder, and the molecular formula of the ferroelectric functional material is [[Ce 2 (H 2 O) 2 (L-(+)-tar) 2 (SO 4 )]·4H 2 O], its molecular structure is...

Embodiment 2

[0024] It is basically the same as Example 1, except that the concentration of sulfuric acid solution is 0.8mol / L, L-(+)-tar is 3mmol, the hydrothermal reaction temperature is 120°C, and the hydrothermal reaction time is 10 days. The stainless steel reactor Cool down to room temperature at a rate of 1°C per hour.

Embodiment 3

[0026] It is basically the same as Example 1, except that the concentration of sulfuric acid solution is 1.2mol / L, L-(+)-tar is 2mmol, the hydrothermal reaction temperature is 200°C, and the hydrothermal reaction time is 3 days. The stainless steel reactor Cool down to room temperature at a rate of 10°C per hour.

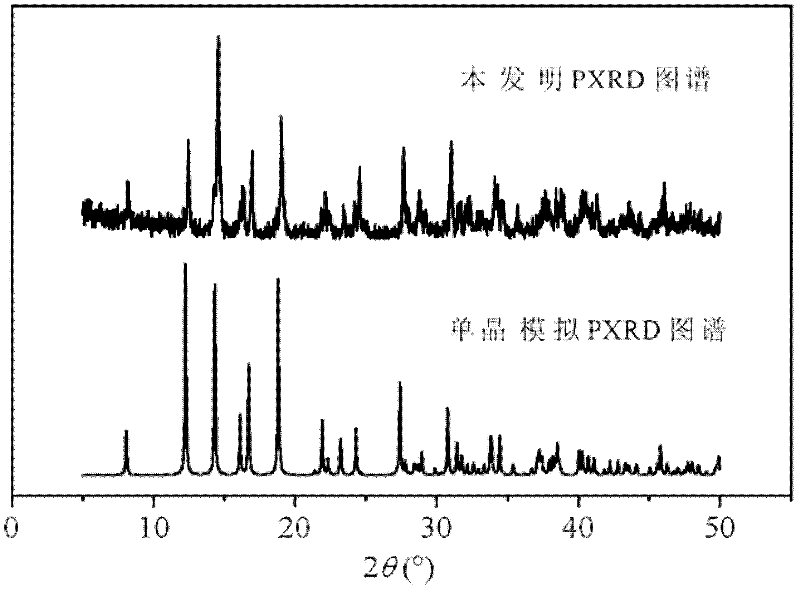

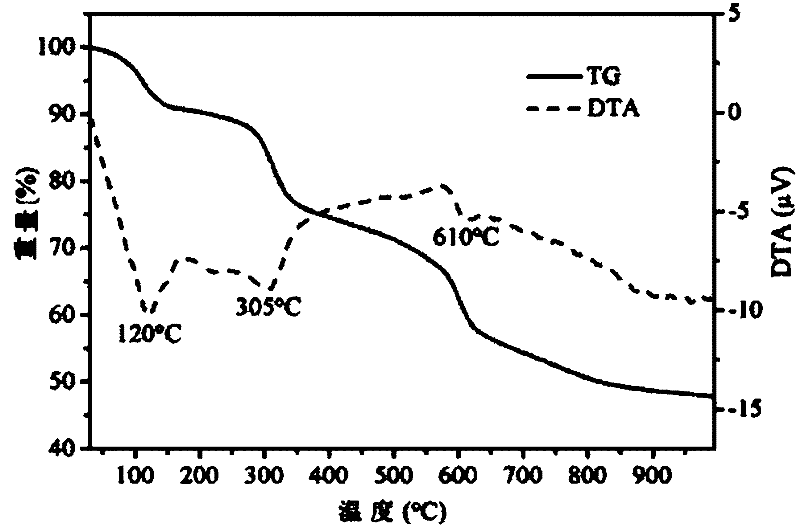

[0027] Using a Bruker D8 Focus powder diffractometer to collect the powder diffraction pattern (PXRD) of the example sample at room temperature at a scanning speed of 6° / min in the 2θ angle range of 5-50°, and compare it with the single crystal simulation PXRD diffraction pattern ,Such as figure 2 The indicated purity is not less than 99%. A Seiko TG / DTA 6300 differential thermal analyzer was used to measure α-Al 2 o 3Be reference substance, under the N2 flow protection of 200ml / min, the TG-DTA (differential thermogravimetry of crystal) curve ( image 3 shown). The hysteresis loops of the samples were tested using the Premier II ferroelectric material testing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| saturated polarization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com