Preparation method and product of modified corn starch chelating agent

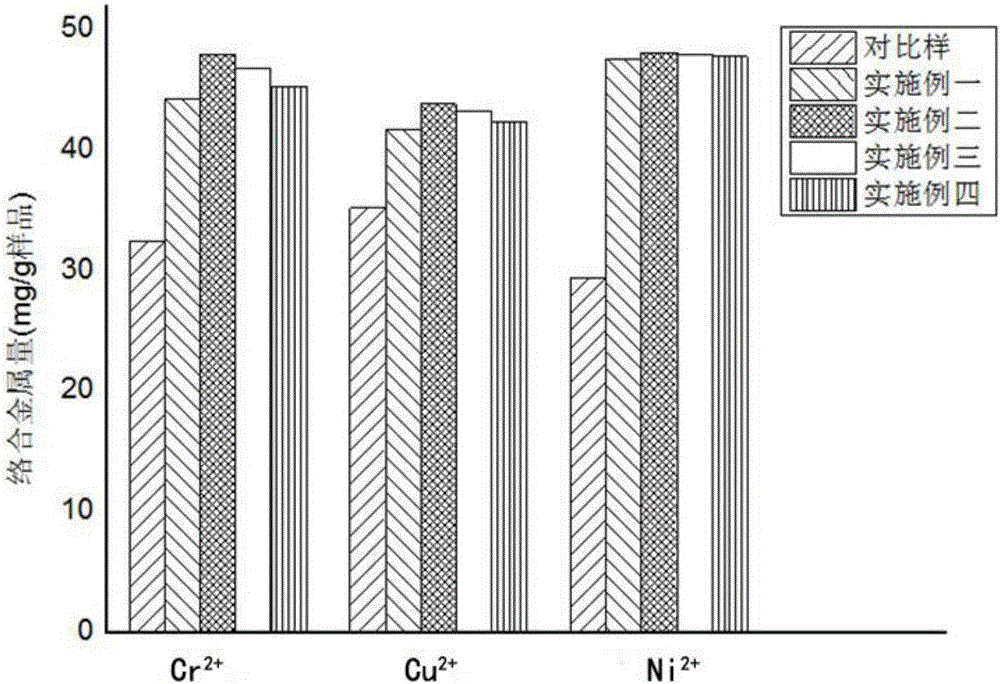

A technology of corn starch and chelating agent, applied in the field of fine chemicals, can solve the problems of easy breakage, limitation of grafting rate of grafted products, high reaction temperature, etc., achieve strong chelating ability, reduce production cost, and high grafting rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The first aspect of the present invention provides a kind of preparation method of modified cornstarch chelating agent, it comprises the following steps:

[0022] (1) 1 weight part of cornstarch is dissolved in 100 weight parts of deionized water, the reaction vessel is evacuated, and nitrogen is vented to keep the nitrogen atmosphere;

[0023] (2) Slowly add 10 to 20 parts by weight of fresh ammonium cerium sulfate-nitric acid solution dropwise to the above-mentioned reaction vessel; in addition, 5 to 15 parts by weight of glycidyl methacrylate are dissolved in deionized water, and then This aqueous solution of glycidyl methacrylate is added in the above-mentioned reaction vessel;

[0024] (3) Keep the nitrogen atmosphere, react the reaction solution in the above-mentioned reaction vessel at a temperature of 5-20°C for 0.3-1.2h, and then neutralize the reaction solution with an ethanol solution of alkali;

[0025] (4) filter cake is obtained by suction filtration, and...

Embodiment 1

[0035] (1) 1 weight part of cationic modified cornstarch is dissolved in 100 weight parts of deionized water, the reaction vessel is evacuated, nitrogen is ventilated, and nitrogen atmosphere is maintained;

[0036] (2) Slowly add 15 parts by weight of fresh ammonium cerium sulfate-nitric acid solution (concentration of nitric acid is 0.05mol / L) dropwise in the above reaction vessel; in addition, 10 parts by weight of glycidyl methacrylate are dissolved in an appropriate Deionized water, and then the aqueous solution of glycidyl methacrylate is added in the above-mentioned reaction vessel;

[0037] (3) Keep the nitrogen atmosphere, react the reaction solution in the above-mentioned reaction vessel at a temperature of 5 to 20° C. for 1 h, then neutralize the reaction solution with an ethanol solution of sodium hydroxide (wherein the concentration of sodium hydroxide is 0.05mol / L), A white precipitate can be seen;

[0038] (4) filter cake is obtained by suction filtration, the ...

Embodiment 2

[0041] (1) 1 weight part of cation-modified cornstarch is dissolved in 100 weight parts of deionized water, the reaction vessel is evacuated, nitrogen is vented, and nitrogen atmosphere is maintained;

[0042] (2) Slowly add 10 parts by weight of fresh ammonium cerium sulfate-nitric acid solution (concentration of nitric acid is 0.05mol / L) dropwise to the above reaction vessel; in addition, 7 parts by weight of glycidyl methacrylate are dissolved in an appropriate amount Deionized water, and then the aqueous solution of glycidyl methacrylate is added in the above-mentioned reaction vessel;

[0043] (3) Keep the nitrogen atmosphere, react the reaction solution in the above reaction vessel at a temperature of 5-20°C for 1.2h, and then neutralize the reaction solution with an ethanol solution of sodium hydroxide (wherein the concentration of sodium hydroxide is 0.05mol / L) , a white precipitate can be seen;

[0044] (4) filter cake is obtained by suction filtration, and described...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com