Preparation method of silver-coated copper conductive powder

A silver-coated copper powder and conductive powder technology, which is applied in transportation and packaging, metal processing equipment, liquid chemical plating, etc., can solve the problems of poor coating effect, poor stability, and decreased electrical conductivity, and achieve reduced surface energy, Stable electrical conductivity, preventing agglomeration and sinking to the bottom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

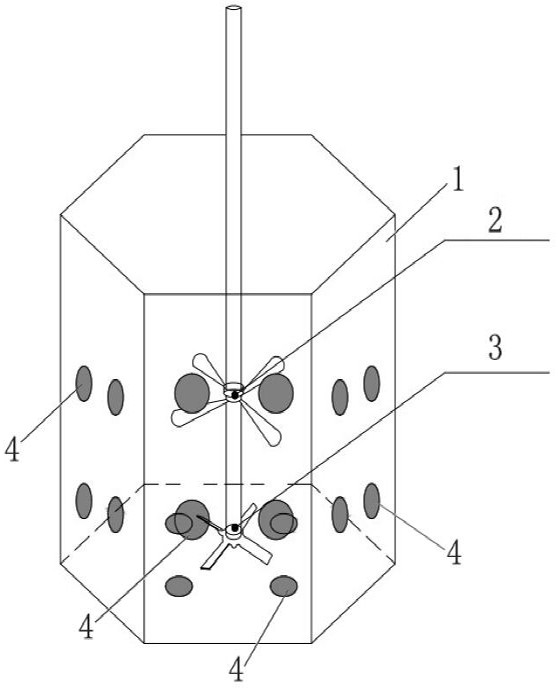

Image

Examples

Embodiment 1

[0027] The first step: dissolve the oily copper powder slurry with a solid content of 1kg in 3kg of diethylene glycol butyl ether, add 25g of sulfuric acid and stir for 30min, filter it with suction, and rinse it with deionized water. After cleaning, the surface is oil-free. Flake copper powder with oxide layer. Organic solvent also can select ethanol for use. The acid may also be acetic acid.

[0028] Step 2: Add 8kg of deionized water containing 430g of EDTA-2Na to the ultrasonic reactor, and then turn on the ultrasonic generator; disperse the cleaned copper powder in the deionized water of the reactor, add 5g of polyvinylpyrrolidone, 5g of BYK180, 2g For ceric sulfate, add tetraethylenepentamine to adjust the pH value to 8. After stirring evenly, add 3.8L of 0.6mol / l silver ammonia solution dropwise with a peristaltic pump. The dropwise addition is completed in 2 hours. After continuing to react for half an hour, add 2L dropwise 0.6mol / l glucose solution, add dropwise in ...

Embodiment 2

[0034] Step 1: Dissolve 1 kg of oily copper powder in 3 kg of ethanol, add 30 g of acetic acid and stir for 30 minutes, filter with suction, rinse with deionized water, and obtain copper powder with no oil and no oxide layer on the surface after cleaning.

[0035] Step 2: Add 8kg of deionized water containing 523g of EDTA-4Na to the ultrasonic reactor, and then turn on the ultrasonic generator; disperse the cleaned copper powder in the deionized water of the reactor, and add 5g of polyoxyethylene octylphenol ether -10, 5g BYK180, 2g ceric sulfate, add ethylenediamine to adjust the pH value to 8, stir evenly, add 3.8L 0.6mol / l silver ammonia solution dropwise with a peristaltic pump, drop it completely in 2 hours, continue to react for half After one hour, 2.4 L of 0.5 mol / l ascorbic acid solution was added dropwise, and the reaction was continued for half an hour after the dropwise addition was completed in one hour. After the reaction is complete, filter and wash to obtain si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com