Electrolyte for anodizing of surface of pure aluminum part and method for anodizing of surface of pure aluminum part

An anodic oxidation and electrolyte technology, applied in the field of electrolyte, can solve the problems of poor oxide film hardness, inability to effectively guarantee wear resistance and control foreign matter, achieve low cost, reduce product discharge accidents, and improve wear resistance performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

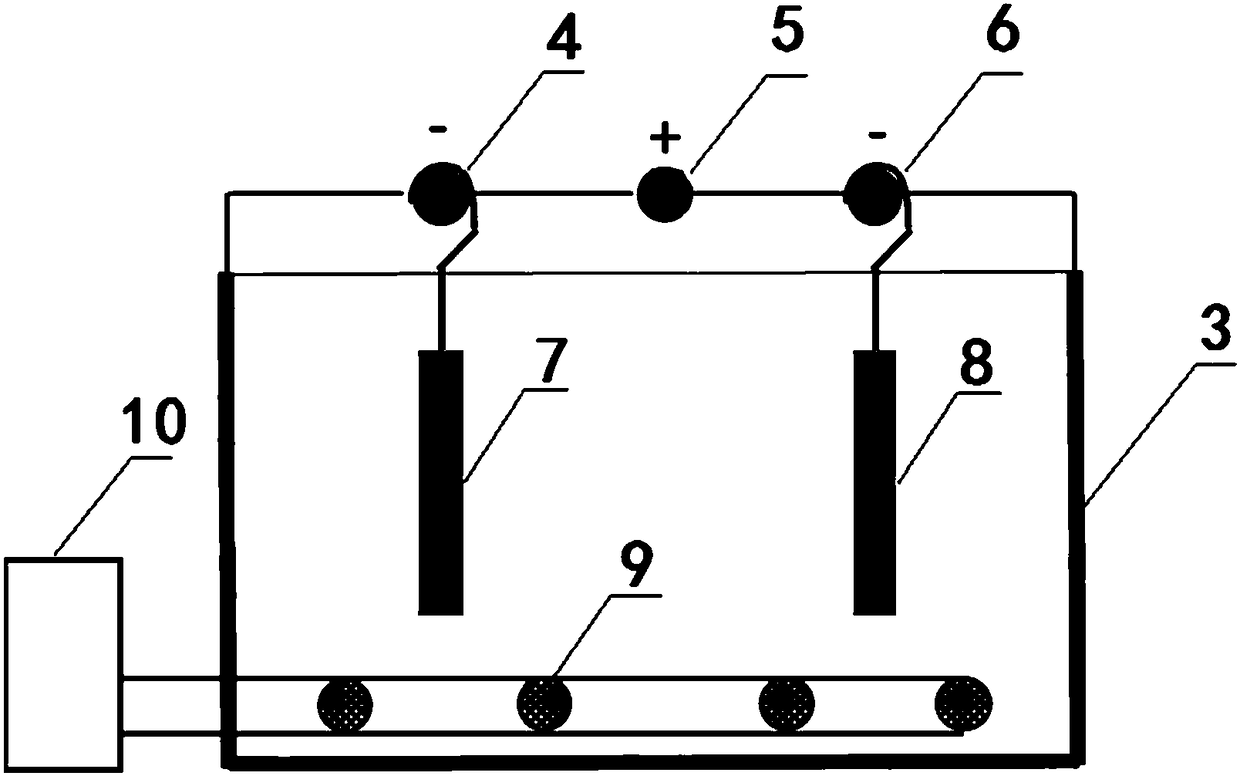

[0031] The electrolytic solution used for anodizing the surface of pure aluminum parts in this embodiment is obtained after adding sulfuric acid, glycerol and ceric sulfate into water and mixing them evenly. The mass concentration of sulfuric acid in the electrolytic solution is 160g / L, and the content of glycerin The volume concentration is 6ml / L, and the mass concentration of ceric sulfate is 3g / L.

[0032] The method for anodizing the surface of pure aluminum parts of the present embodiment comprises the following steps:

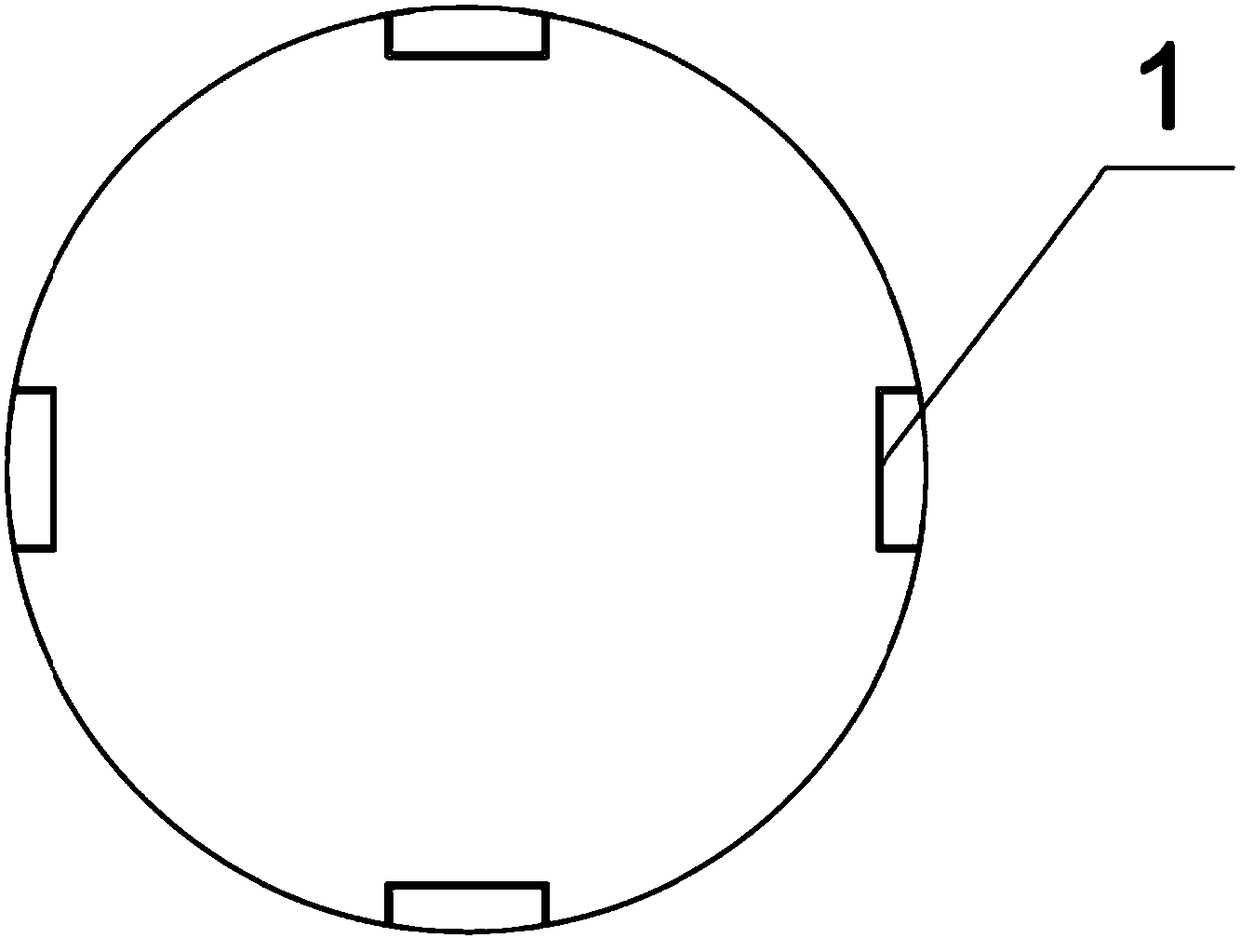

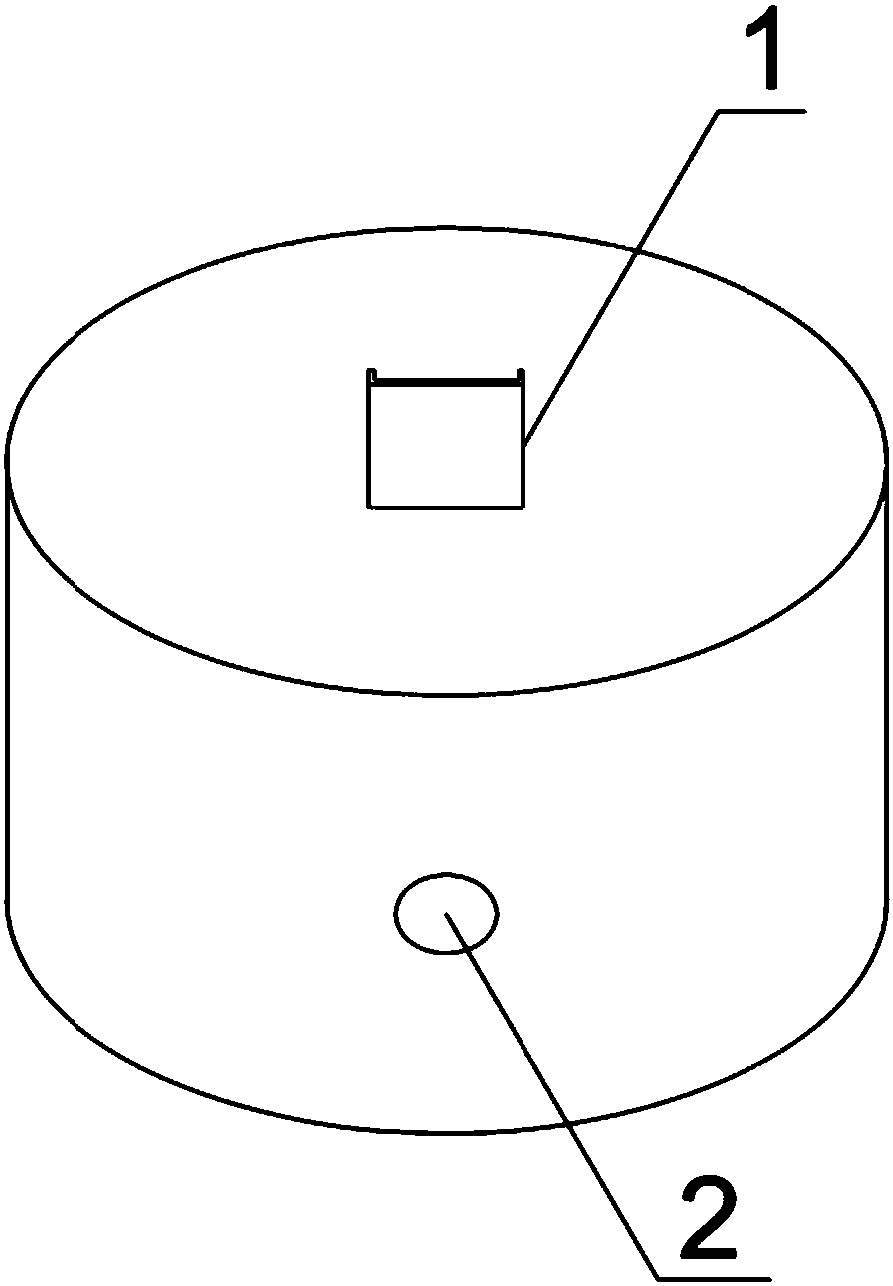

[0033] 1) Check whether there are bumps and scratches on the surface of the shield, and select a shield without bumps and scratches to degrease with a thinner organic solvent;

[0034] 2) Apply acid and alkali corrosion-resistant glass glue on the conductive part of the shield and cure it to shield the conductive part;

[0035] 3) Soak the shield in inorganic acid for 5s to degrease, then use 25°C water to clean the shield for 1min; then immerse the shield...

Embodiment 2

[0041] The electrolytic solution used for anodizing the surface of pure aluminum parts in this embodiment is obtained after adding sulfuric acid, glycerin and ceric sulfate into water and mixing them evenly. The mass concentration of sulfuric acid in the electrolytic solution is 155g / L, and the content of glycerin The volume concentration is 8ml / L, and the mass concentration of ceric sulfate is 2g / L.

[0042] The method for anodizing the surface of pure aluminum parts of the present embodiment comprises the following steps:

[0043] 1) Check whether there are bumps and scratches on the surface of the shield, and select a shield without bumps and scratches to degrease with a thinner organic solvent;

[0044] 2) Apply acid and alkali corrosion-resistant glass glue on the conductive part of the shield and cure it to shield the conductive part;

[0045] 3) Soak the shield in inorganic acid for 4s to degrease, then use 25°C water to clean the shield for 1min; then immerse the shie...

Embodiment 3

[0051] The electrolytic solution used for anodizing the surface of pure aluminum parts in this embodiment is obtained after adding sulfuric acid, glycerol and ceric sulfate into water and mixing them evenly. The mass concentration of sulfuric acid in the electrolytic solution is 165g / L, and the content of glycerin The volume concentration is 4ml / L, and the mass concentration of ceric sulfate is 4g / L.

[0052] The method for anodizing the surface of pure aluminum parts of the present embodiment comprises the following steps:

[0053] 1) Check whether there are bumps and scratches on the surface of the shield, and select a shield without bumps and scratches to degrease with a thinner organic solvent;

[0054] 2) Apply acid and alkali corrosion-resistant glass glue on the conductive part of the shield and cure it to shield the conductive part;

[0055] 3) Soak the shield in inorganic acid for 3s to degrease, then use 20°C water to clean the shield for 2min; then immerse the shie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com