Roughening treatment process and equipment for lead-free soldering electrolytic copper foils

A technology of roughening and electrolytic copper foil, which is applied in electrolytic process, electrolytic components, etc., can solve environmental hazards and other problems, and achieve the effect of uniform appearance color, permeability and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

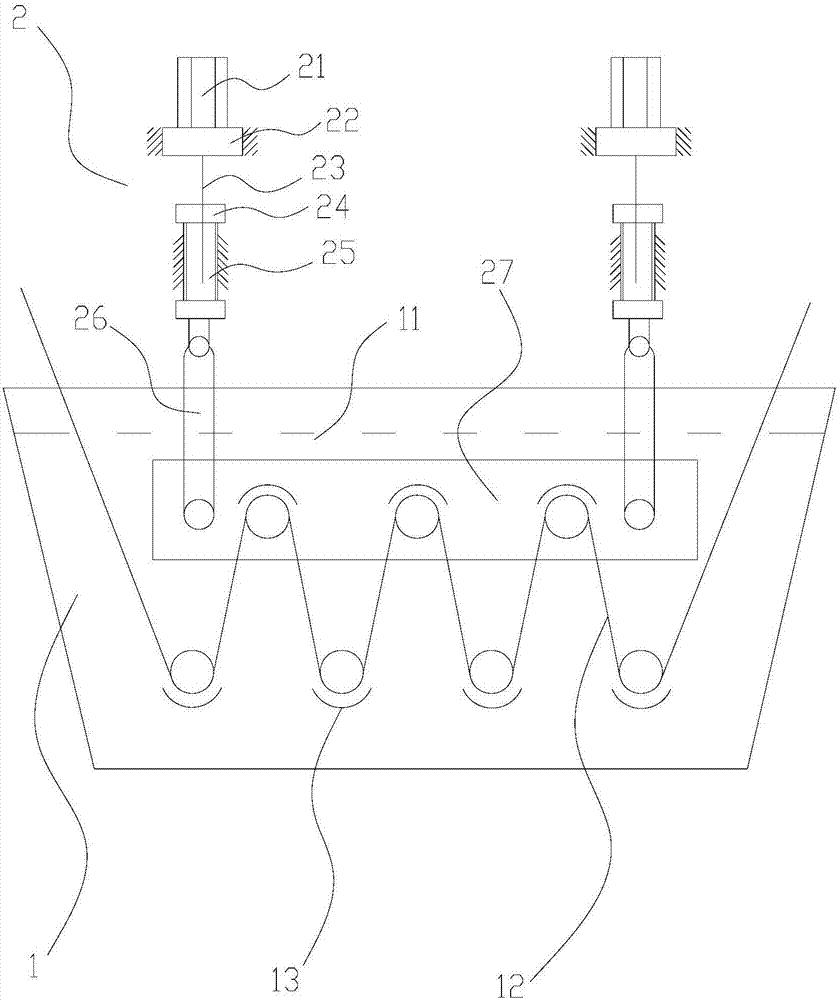

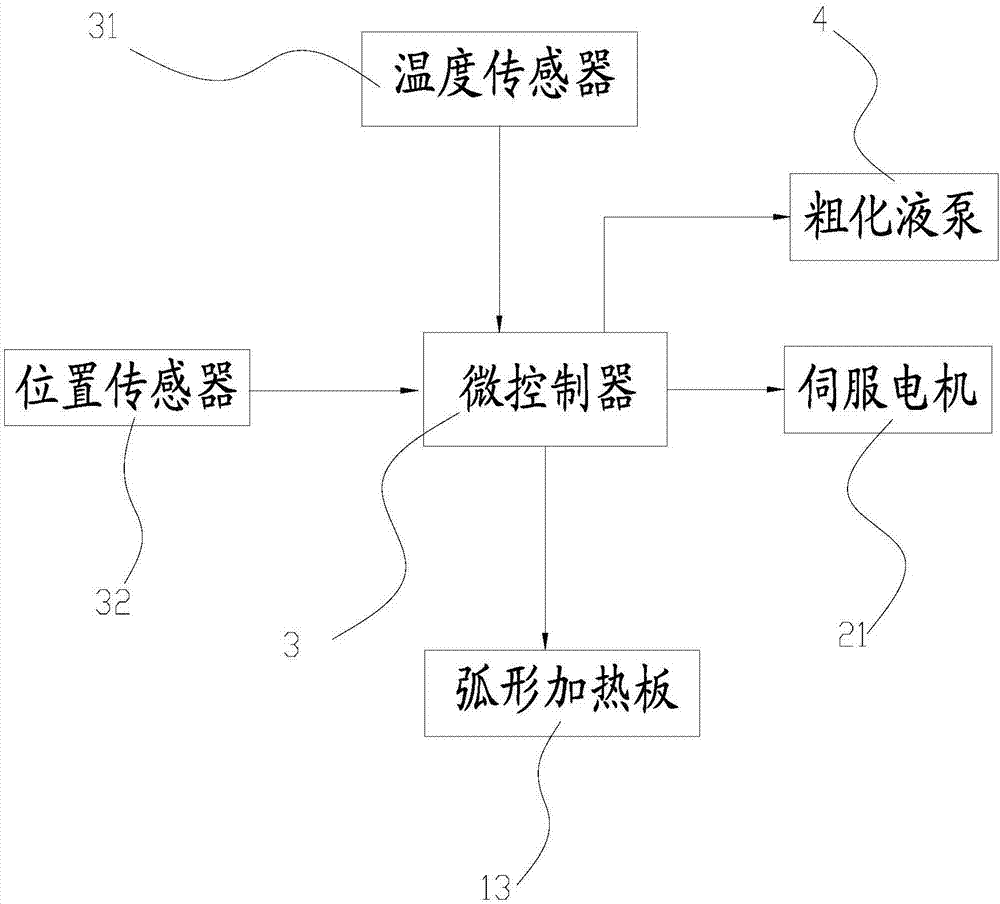

Embodiment Construction

[0036] In order to fully understand the technical content of the present invention, the technical solutions of the present invention will be further introduced and illustrated below in conjunction with specific examples, but not limited thereto.

[0037] This example is a specific description of a certain combination of additives used in the roughening treatment process of electrolytic copper foil. It is a roughening treatment process for lead-free soldering electrolytic copper foil. In the treatment process, sodium tungstate, A combined additive composed of at least three compounds of sodium molybdate, sodium nitrite, stannous sulfate, hydrochloric acid, cerium sulfate, and ceric sulfate. Specifically, the combined additives include components at the following concentrations: 10-100 ppm of sodium tungstate, 5-50 ppm of stannous sulfate, 10-100 ppm of hydrochloric acid, and 20-150 ppm of cerium sulfate.

[0038] In other embodiments, a roughening treatment process for lead-fre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com