Manufacturing Process of Polyurethane Tape

A polyurethane and manufacturing process technology, which is applied in the manufacturing process field of polyurethane tapes, can solve the problems of difficult control, bad waste, thick but not hard finished products, etc., and achieves easy operation and shortened time controllability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with embodiment the present invention is further described.

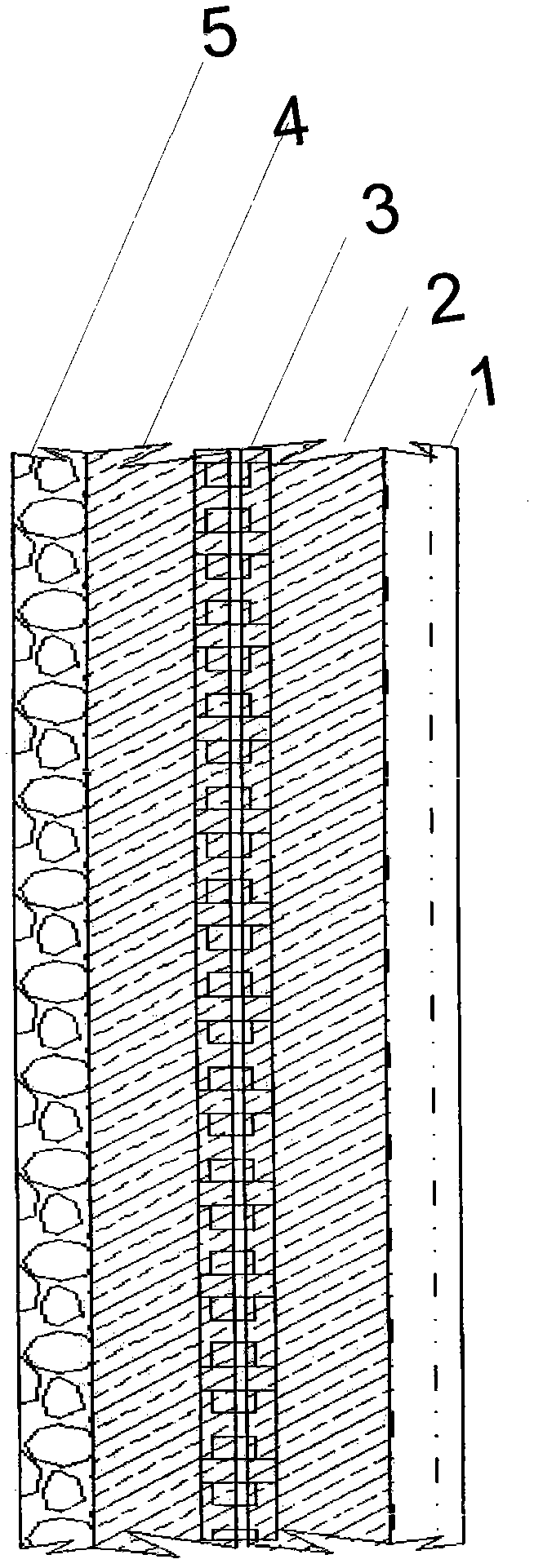

[0014] Such as figure 1 Shown, a polyurethane belt manufacturing process, including

[0015] A. Preheat the mold single-sided body; in the environment where the conventional indoor temperature is lower than 25°C, heating equipment is required to raise the indoor temperature or the heat of the mold to above 25°C;

[0016] B. Production of synthetic prepolymer 1: select raw materials with 40 times physical expansion to prepare the copolymer, and after the preparation is completed, evenly paint a layer of copolymer on the surface of the mold, and the copolymer will expand to form skin and solidify;

[0017] C. Production of dry strong chain body 2: After curing, it will not stick to hands, then evenly brush a layer of copolymer, spread the cut fiber cloth on the copolymer, brush evenly with a brush and press it flat, wait After the skin is not sticky, the copolymer is evenly painted again,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com