Hydraulic brake controller

A hydraulic brake and controller technology, applied in bicycle brakes, hydraulic brake transmissions, bicycle accessories, etc., can solve problems such as affecting the braking sensitivity, affecting the time when the piston passes through the oil return hole, and the force of the piston dispersed, so as to achieve reliable lifting. The effect of perfect degree, structure and function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

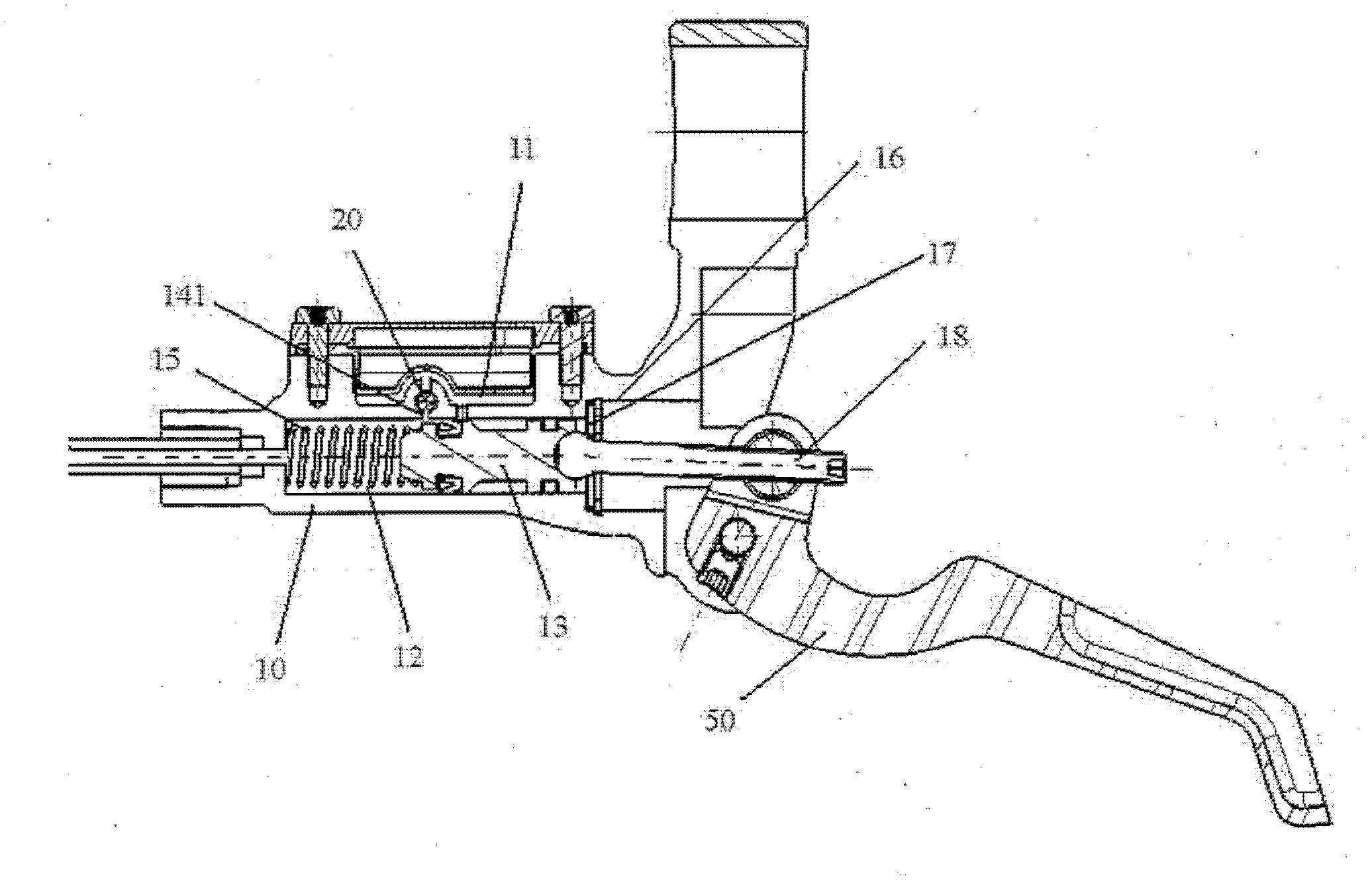

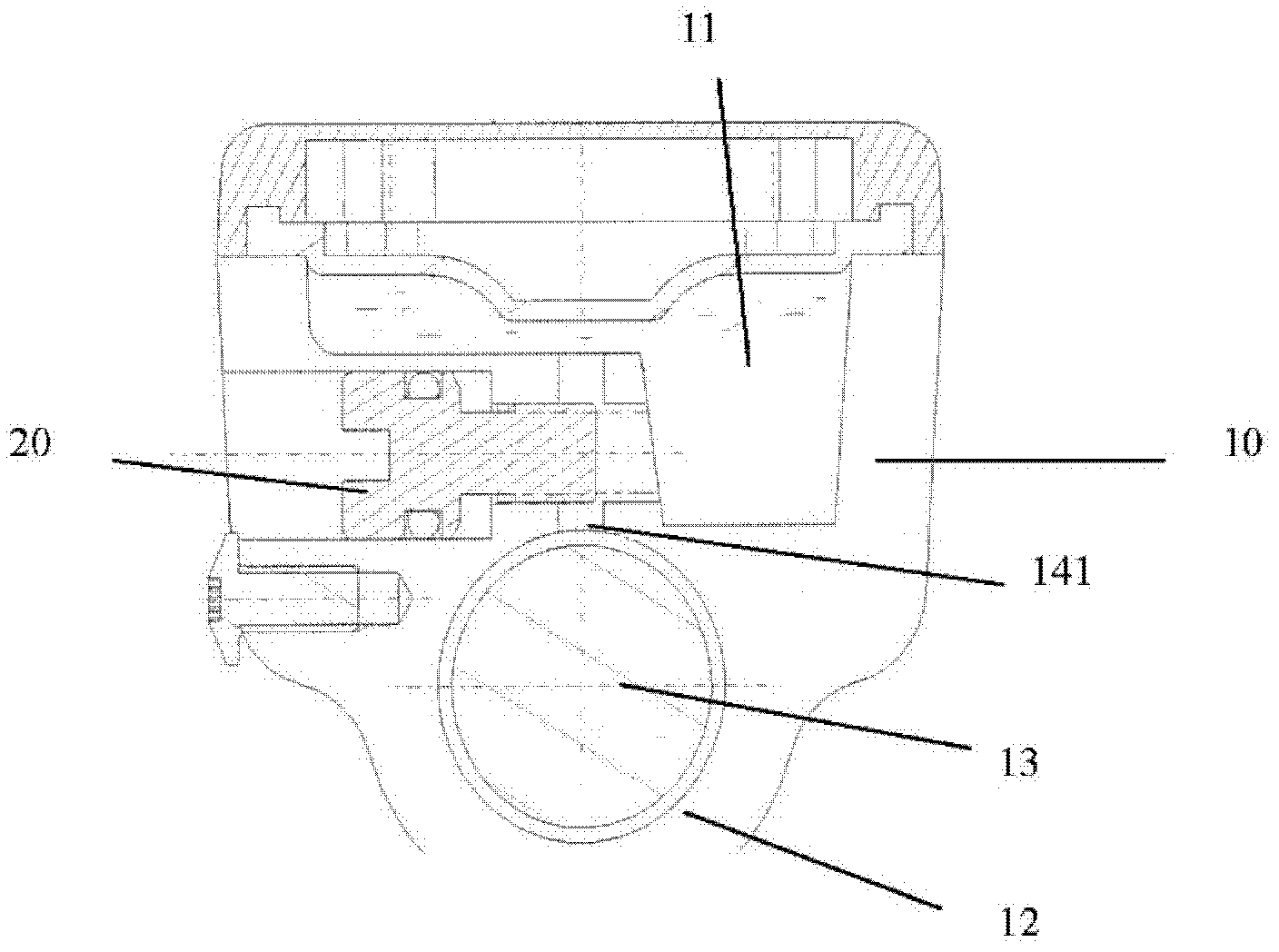

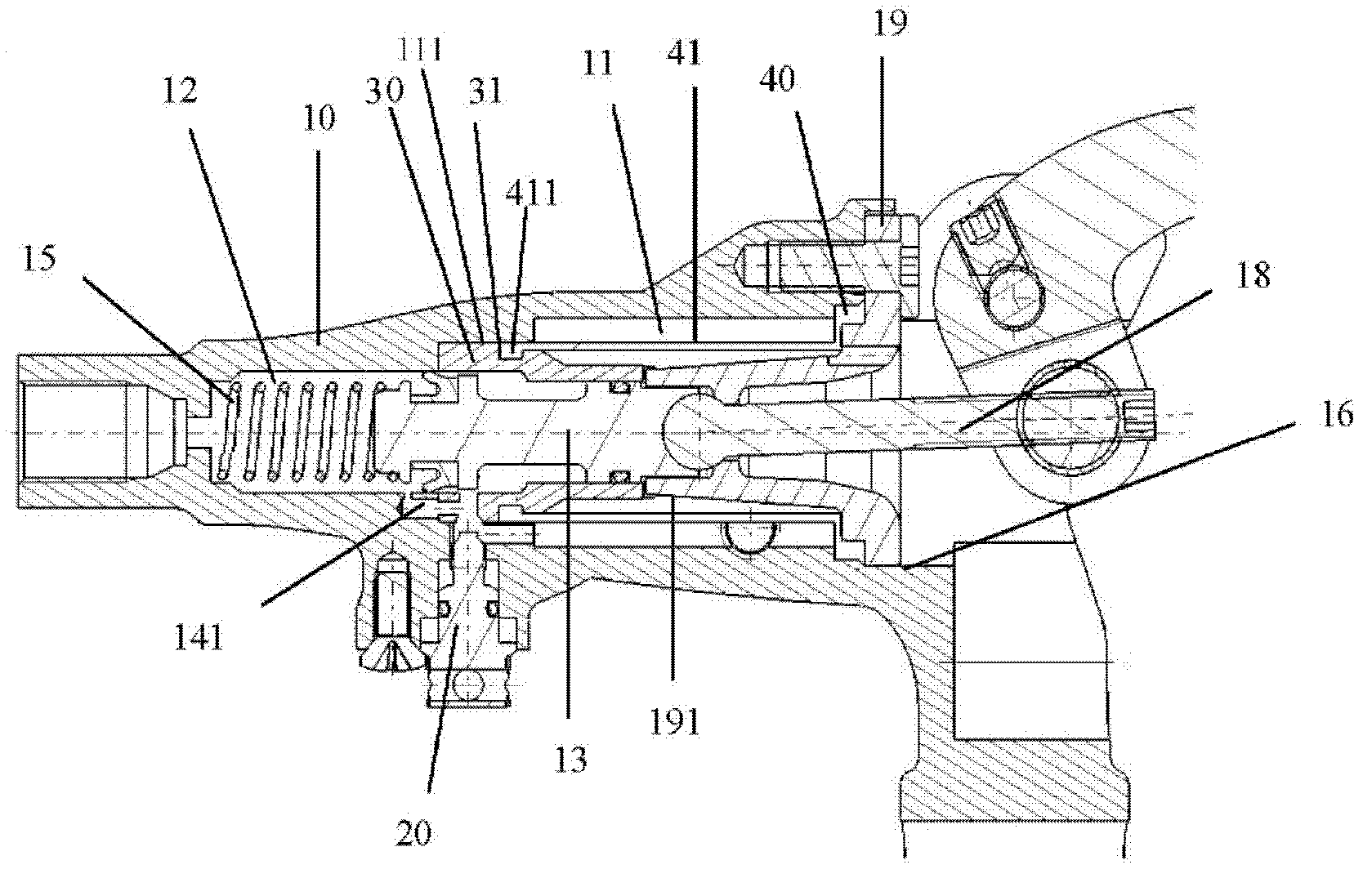

[0054] Such as figure 1 A sectional view of the axial structure of the hydraulic brake controller according to the first embodiment of the present invention, figure 2 As shown in the radial structural sectional view of the hydraulic brake controller of the first embodiment of the present invention, the hydraulic brake controller of the present invention is provided with an oil storage space 11 on a controller body 10 for storing hydraulic oil, and a main oil cylinder 12 for supplying hydraulic oil. Through the hydraulic pipeline (not shown in the figure), it is connected with the auxiliary oil cylinder of at least one brake caliper (not shown in the figure). The main oil cylinder 11 is further provided with a piston 13 that can be driven by the brake handle 50 to move back and forth relative to the inside of the main oil cylinder 12 .

[0055]It is characterized in that: the controller body 10 is provided with a first oil return hole 141 connected to the oil storage space 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com