Multilayer heat insulation plastic steel greenhouse

A multi-layer thermal insulation and plastic steel technology, applied in thermal insulation, greenhouse cultivation, gardening, etc., can solve the problems of increasing power heating, increasing unsafe hidden dangers, increasing costs, etc., and achieves the effect of various specifications, complete functions and complete structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

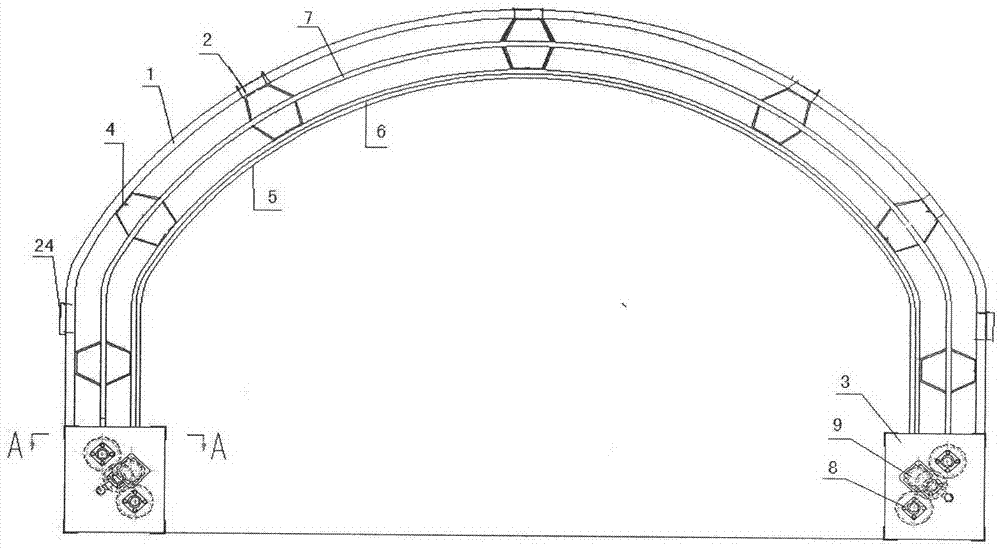

[0024] Embodiment: Take the three-layer film arched greenhouse as an example:

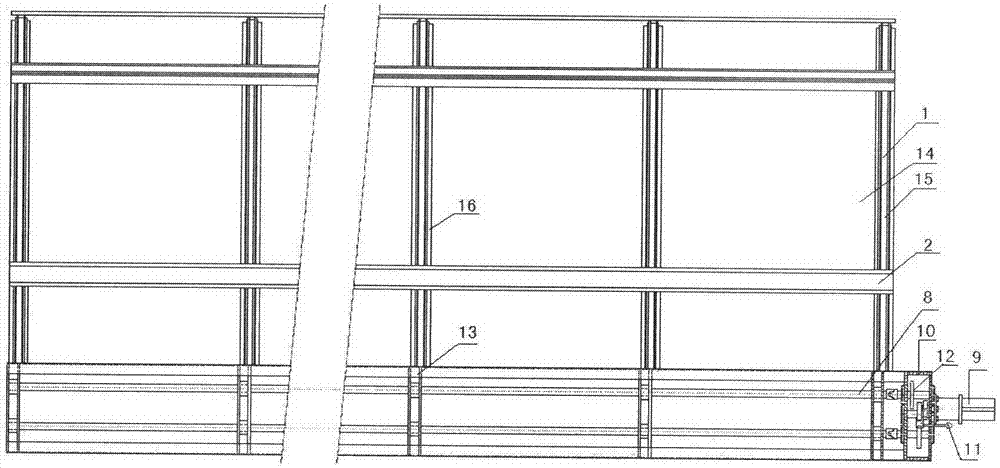

[0025] This new type of greenhouse is a vegetable greenhouse assembled from plastic profiles and steel purlins. It is composed of plastic profiles, steel purlin frame, trapezoidal support frame, zipper, greenhouse outer membrane, greenhouse inner membrane, mechanical transmission and other parts. Its inner membrane can be combined into two or more layers of retractable movable membrane according to the needs, and the retractable action is completed through mechanical transmission, so as to achieve the function of keeping out the cold and heat preservation.

[0026] Multi-layer thermal insulation plastic steel greenhouses are: plastic steel structure greenhouses, among which,

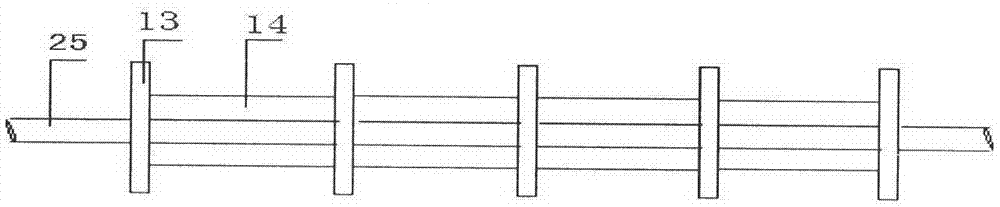

[0027] 1. Steel purlin frame: a total of two floors. In order to enhance the strength, the upper layer is made of hot-dip galvanized strip plate and cold-rolled into C or U-shaped steel such as Figure 5 , the lower layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com