A unitized combined assembly type layer hen welfare breeding cage

A combined assembly and unitized technology, applied in the poultry industry, poultry cages or houses, applications, etc., can solve the problems of free-range free-range breeding of difficult laying hens, non-automatic egg collection, light leakage and open-air egg production areas, etc. Achieve the effect of improving the level of welfare breeding, perfect structure and function, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following is a further description of a unitized combined assembly type welfare breeding cage for laying hens of the present invention in combination with the accompanying drawings and specific implementation methods given by the inventor. All the components not described in detail in the present invention, or the connection relationship between the components, all adopt the prior art.

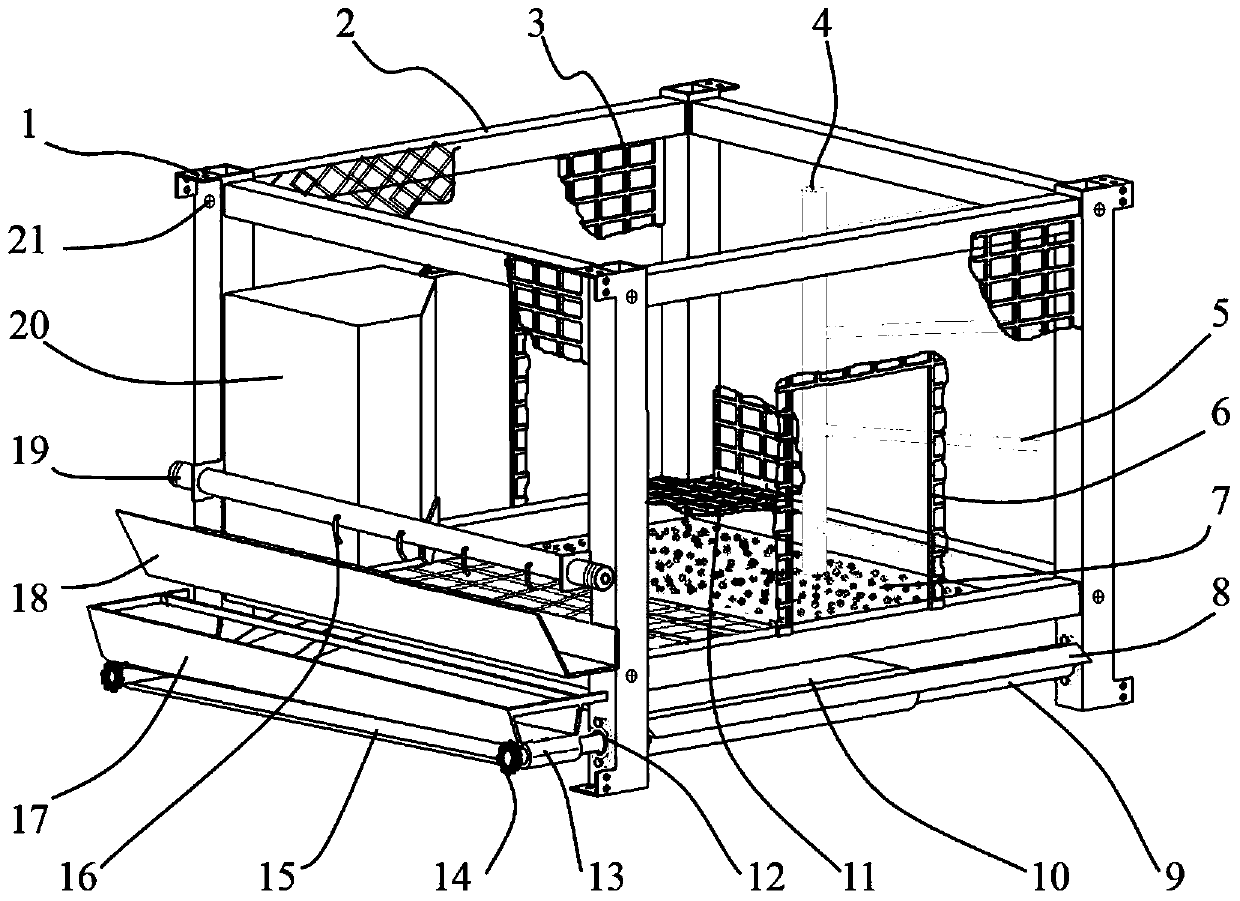

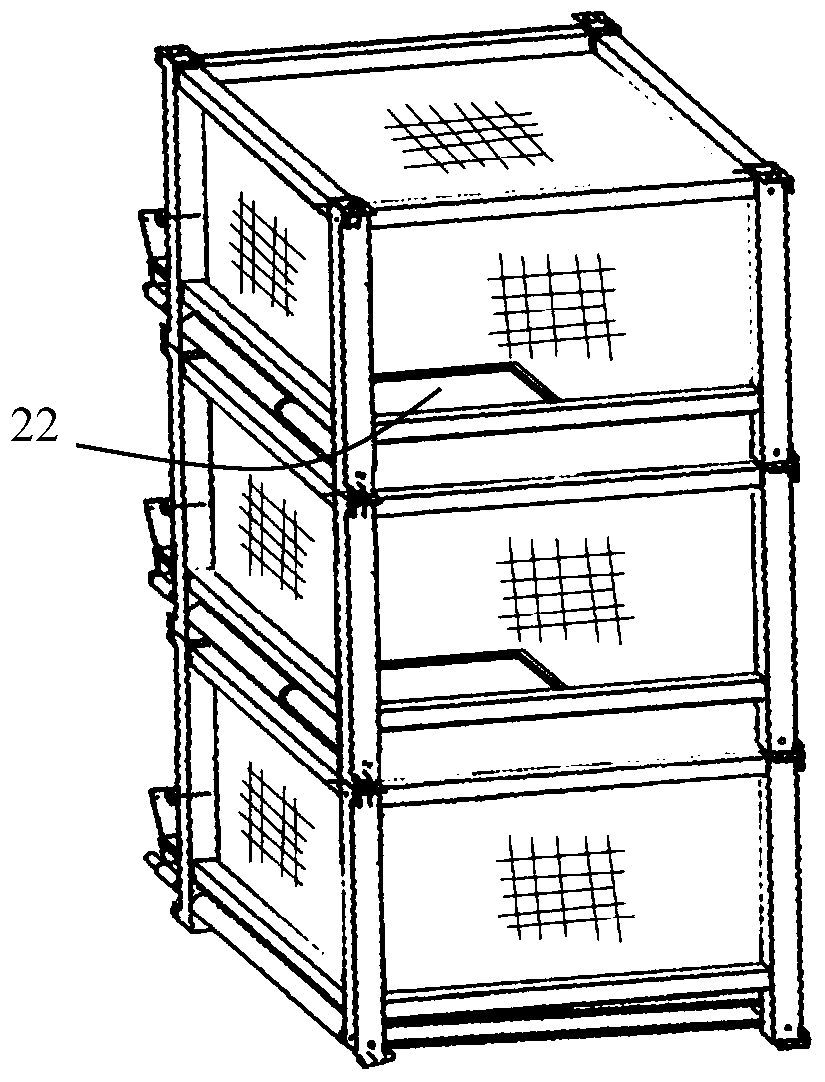

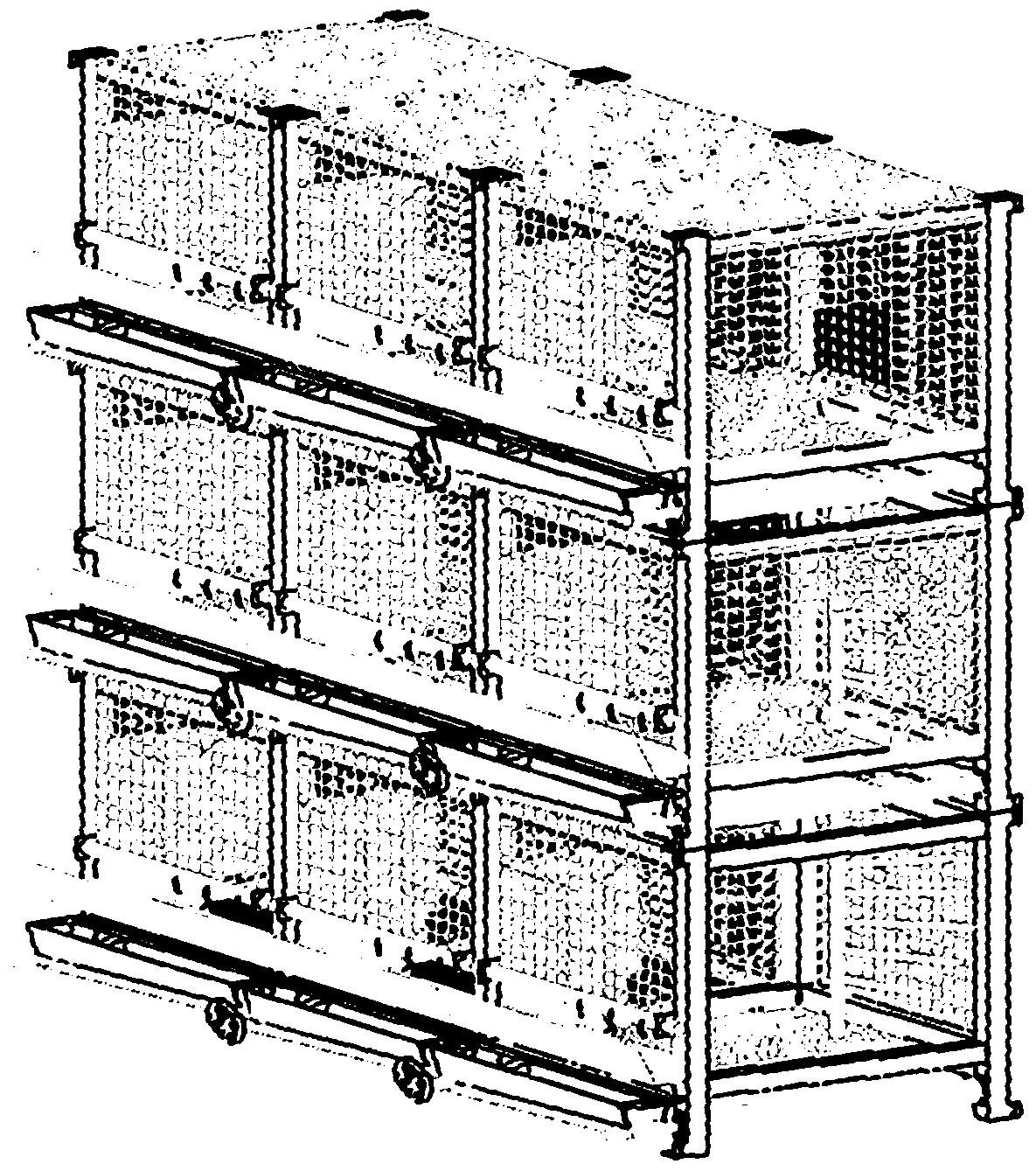

[0027] figure 1 It is a schematic diagram of the monomer structure of a unitized combined assembly type welfare breeding cage for laying hens in the present invention, which includes support feet 1, pipe frames 2, surface nets 3, perch columns 4, perch rods 5, dodge doors 6, artificial Meadow 7, manure scraper 8, roller shaft 9, manure cleaning belt 10, frame layer 11, rolling member 12, egg rolling plate 13, synchronous teeth 14, egg collection belt 15, nipple drinker 16, egg baffle plate 17, food Groove 18, drinking water pipe 19, egg-laying box body 20, connection pin 21, interl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com