Preparation method of cerium oxide with large specific surface area

A large specific surface, cerium oxide technology, applied in chemical instruments and methods, rare earth metal oxide/hydroxide, metal/metal oxide/metal hydroxide catalyst, etc., can solve the reduction of specific surface area and affect the catalytic effect. and other problems, to achieve the effect of low cost, good catalytic effect and good environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

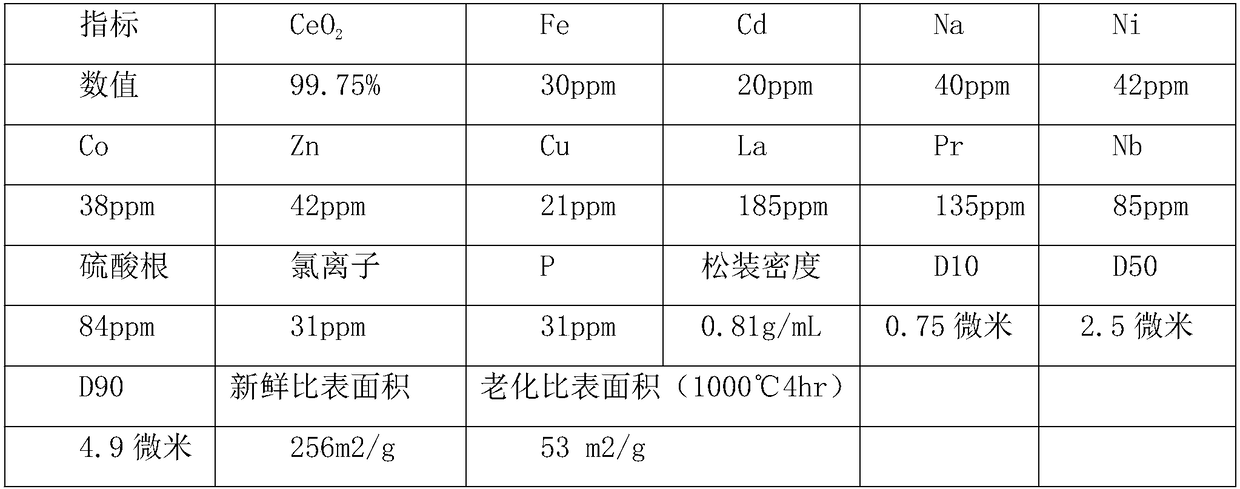

Embodiment 1

[0031] A method for preparing cerium oxide with a large specific surface, comprising the following steps:

[0032] (1) Dosing, industrial pure ceric sulfate is mixed with the ceric sulfate solution that concentration is 181g / L, and constant temperature is 41 ℃ to temperature, and industrial pure ammonium carbonate is mixed with the ammonium carbonate solution that concentration is 585g / L, And keep the temperature at 41°C, prepare industrial pure oxalic acid into an oxalic acid solution with a concentration of 103g / L, and keep the temperature at 41°C;

[0033] (2) Reaction, put the prepared oxalic acid solution into the reaction kettle, and keep the temperature until the temperature is 40°C. The reaction kettle has a built-in cooling coil, and then stir at a stirring speed of 110r / min. Add 0.11 times the volume of the oxalic acid solution Ammonium solution, continue to stir for 20 minutes after adding, as the bottom liquid, then add ceric sulfate solution and ammonium carbonate...

Embodiment 2

[0042] A method for preparing cerium oxide with a large specific surface, comprising the following steps:

[0043] (1) dosing, the industrial pure ceric sulfate is mixed with the ceric sulfate solution that concentration is 182g / L, and constant temperature is 40 ℃ to temperature, and industrial pure ammonium carbonate is mixed with the ammonium carbonate solution that concentration is 585g / L, And keep the temperature until the temperature is 40°C, prepare industrial pure oxalic acid into an oxalic acid solution with a concentration of 103g / L, and keep the temperature until the temperature is 40°C;

[0044] (2) Reaction, put the prepared oxalic acid solution into the reaction kettle, and keep the temperature until the temperature is 41°C, the reaction kettle has a built-in cooling coil, then stir, the stirring speed is 108r / min, add 0.105 times the volume of carbonic acid solution of the oxalic acid solution Ammonium solution, continue to stir for 23 minutes after adding, as th...

Embodiment 3

[0053] A method for preparing cerium oxide with a large specific surface, comprising the following steps:

[0054] (1) dosing, industrial pure ceric sulfate is mixed with the ceric sulfate solution that concentration is 184g / L, and constant temperature is 40.5 ℃ to temperature, and industrial pure ammonium carbonate is mixed with the ammonium carbonate solution that concentration is 585g / L, And keep the temperature until the temperature is 40°C, prepare industrial pure oxalic acid into an oxalic acid solution with a concentration of 101g / L, and keep the temperature until the temperature is 40°C;

[0055] (2) Reaction, put the prepared oxalic acid solution into the reaction kettle, and keep the temperature until the temperature is 41°C, the reaction kettle has a built-in cooling coil, and then stir at a stirring speed of 115r / min, add 0.115 times the volume of carbonic acid of the oxalic acid solution Ammonium solution, continue to stir for 25 minutes after adding, as the botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com