Improved water quenching slag adsorbent and preparation method thereof

A technology for modifying water and adsorbents, which is applied in chemical instruments and methods, adsorption water/sewage treatment, and other chemical processes. It can solve the problem of high cost of adsorbent treatment, achieve easy operation, reduce production costs, and improve adsorption capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

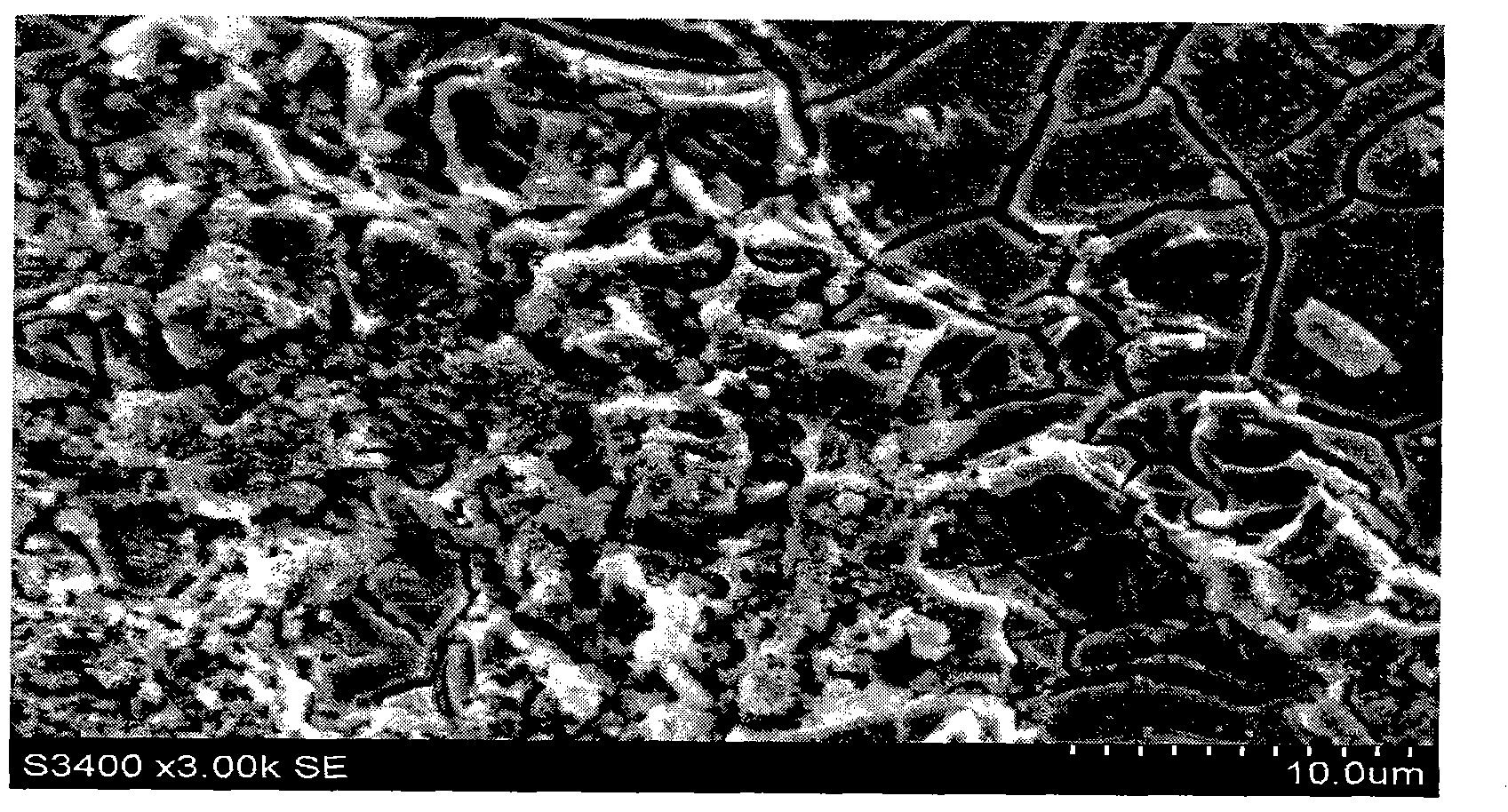

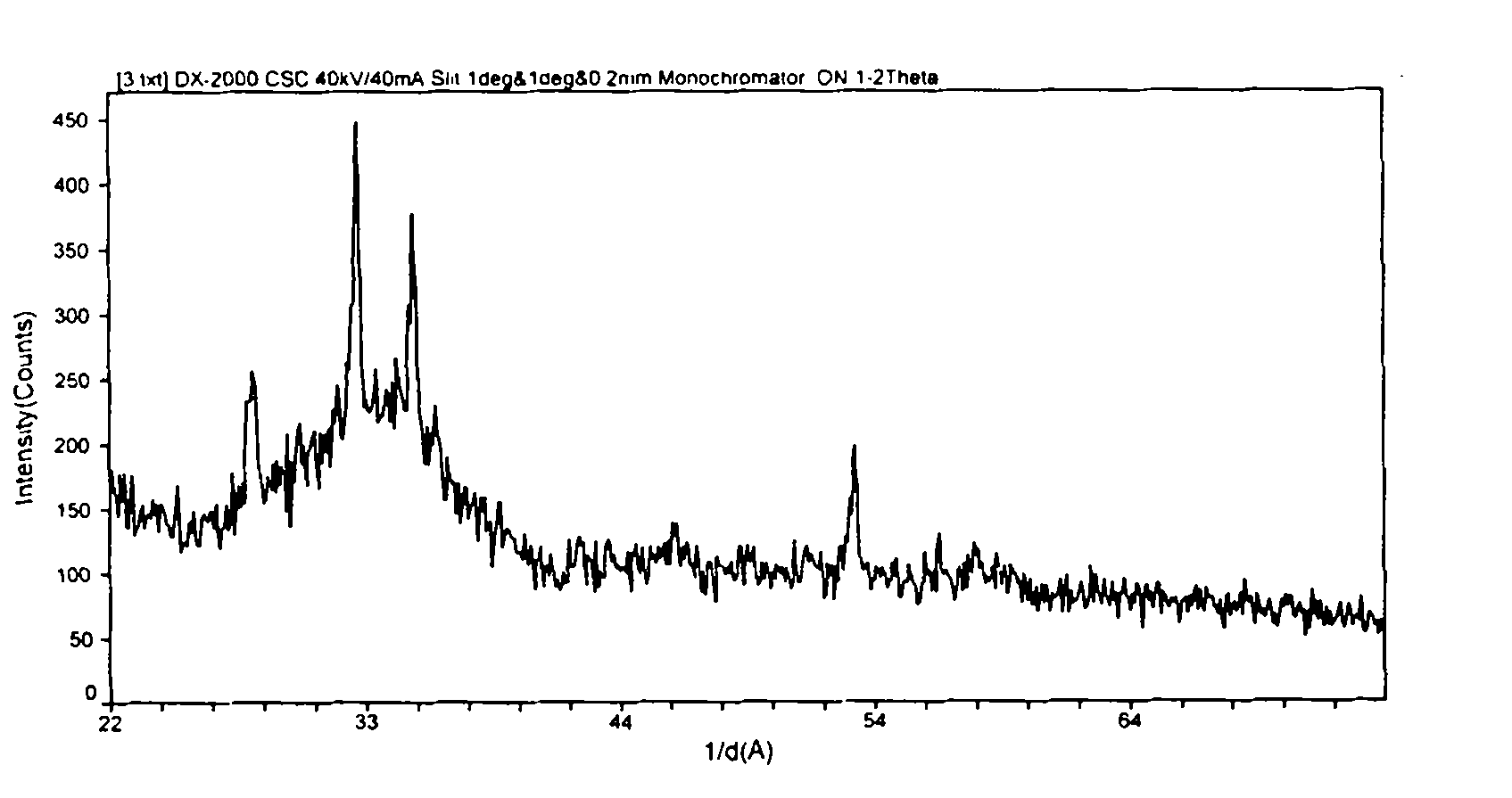

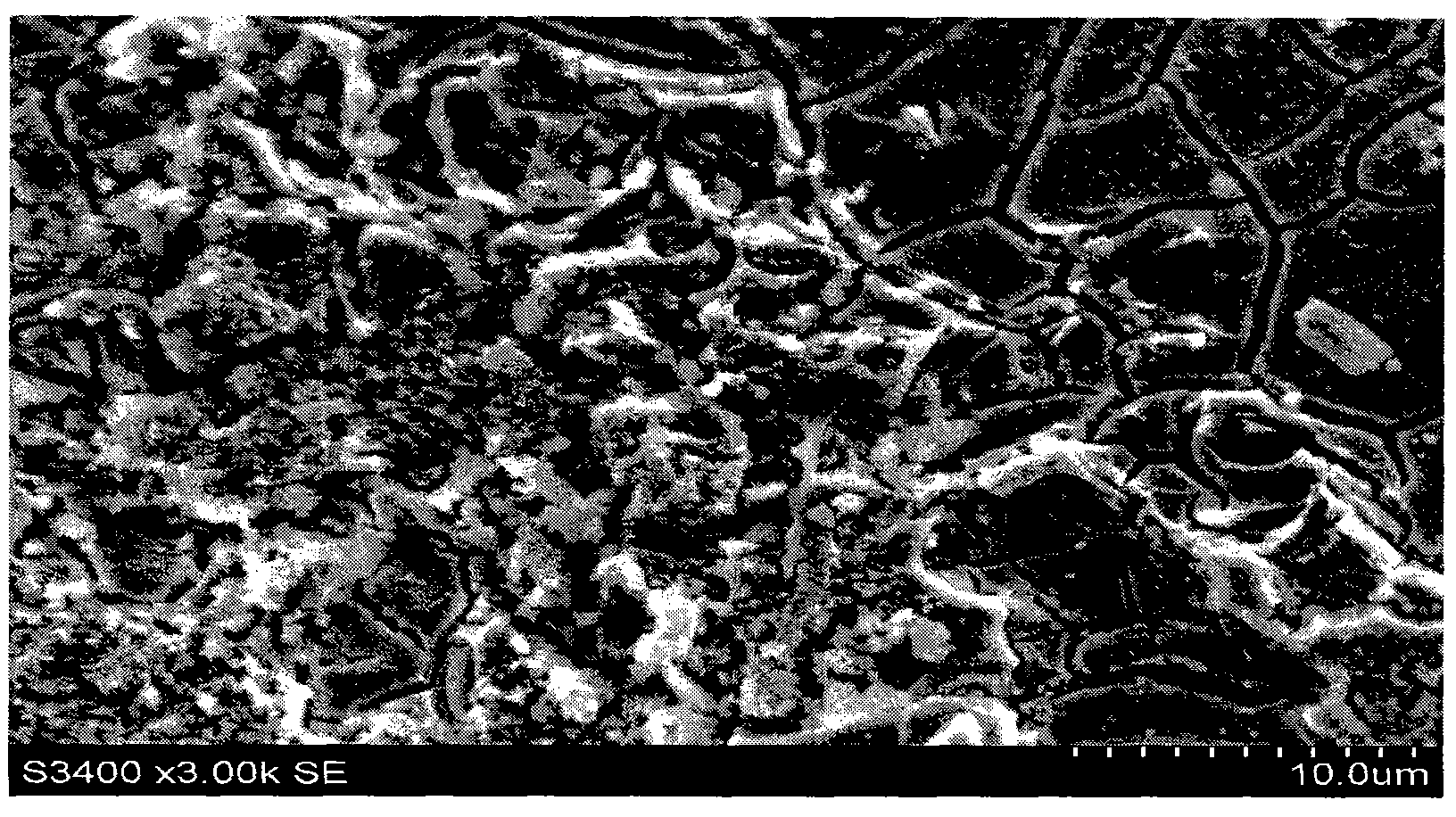

[0012] Embodiment 1: The raw material of the present invention is taken from the blast furnace water-quenched slag of the No. 4 blast furnace of Baotou Iron and Steel Group Company Ironworks. The preparation method is as follows: 1) The blast furnace water-quenched slag is repeatedly washed with water for 3-4 times, and then placed in an oven Dried at 100°C, thoroughly ground in a mortar, and sieved through a 100-mesh sieve. 2) Mix 100 g of blast furnace water-quenched slag pretreated in step 1) with 1.5 g of cerium sulfate and 2 g of ferric chloride, stir well, and fully wet the mixture with 80 g of water, stir evenly, and then fully The wetted mixture was dried in an oven at a temperature of 100°C. 3) Fully grind the dried mixture in step 2) evenly, and then sieve it through a 100-mesh sieve, and place the sieved mixture in a muffle furnace at 500° C. for 1-2 hours to obtain the obtained Modified water quenching slag adsorbent. Under the condition of pH=8, weigh 1 g of the...

Embodiment 2

[0013] Embodiment 2: The raw material of the present invention is taken from the blast furnace water-quenched slag of the No. 4 blast furnace of Baotou Iron and Steel Group Company Ironworks. The preparation method is as follows: 1) The blast furnace water-quenched slag is repeatedly washed with water for 3-4 times, and then placed in an oven Dried at 100°C, thoroughly ground in a mortar, and sieved through a 100-mesh sieve. 2) Mix 100 g of the raw water quenching slag pretreated in step 1) with 3 g of cerium sulfate and 4 g of ferric chloride, stir well, and fully wet the mixture with 85 g of water, stir evenly, and then fully wet the mixture 3) Use a mortar to fully grind the dried mixture in step 2) evenly, then pass it through a 100-mesh sieve for sieving, and place the sieved mixture in The modified water-quenched slag adsorbent is obtained by roasting in a muffle furnace at a temperature of 500° C. for 1-2 hours. Under the condition of pH=8, weigh 1 g of the prepared mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com