Preparation method for mesoporous silica material

A technology of mesoporous silica and nanomaterials, applied in the direction of silica, silicon oxide, nanotechnology for materials and surface science, etc., can solve problems such as limitations, achieve regular shape, mild operating conditions, and particle size even diameter effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

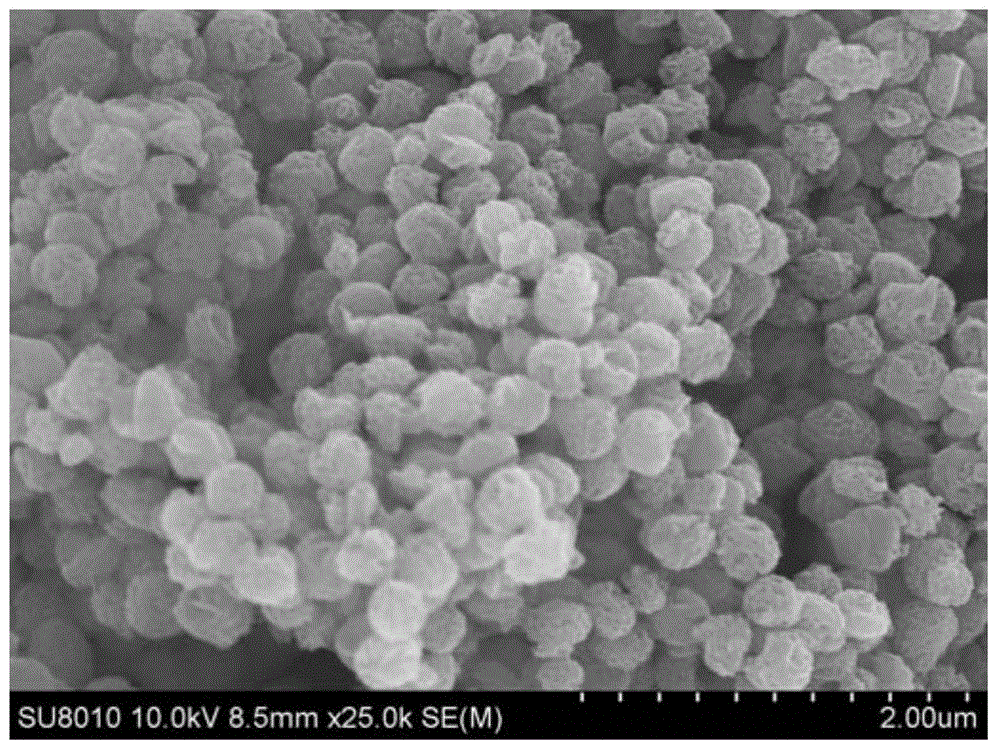

Embodiment 1

[0038] A method for preparing a mesoporous silicon dioxide nanomaterial, comprising the steps of:

[0039] (1) At room temperature, according to the total surfactant concentration of 0.028mol / L, weigh 0.5715g of cetyltrimethylammonium bromide and 0.1366g of sodium dodecylbenzenesulfonate into 70mL of deionized water, 50Hz Ultrasound at high power for 20 minutes to obtain a clear solution, and then let it stand for 24 hours;

[0040] (2) At room temperature, add 0.8mL of ammonia solution with a mass fraction of 25% to 28% to the clear solution obtained in step (1), then add 5mL of ethanol solution and 20mL of ether solution in turn, stir vigorously for 30min; then quickly add 2.5g tetraethyl orthosilicate solution, vigorously stirred for 4 hours, and a solid precipitate was formed;

[0041] (3) Suction filter the solid precipitate obtained in step (2), wash it with water and ethanol three times respectively, and then place it in a drying oven at 60-80°C for more than 24 hours;...

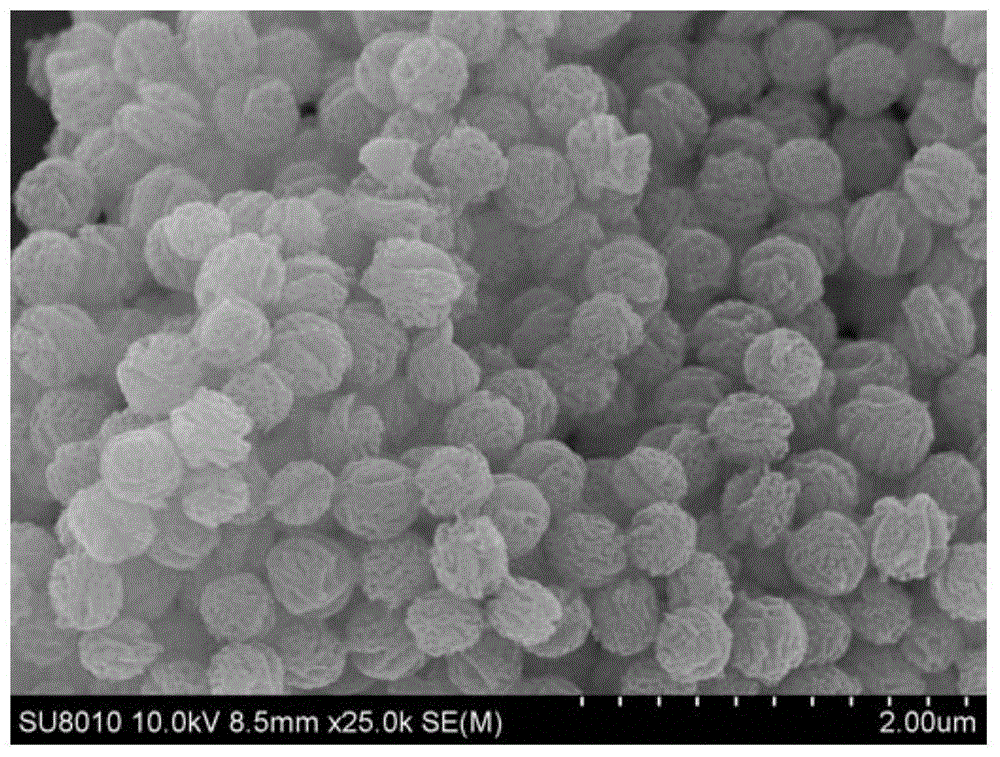

Embodiment 2

[0044] A method for preparing a mesoporous silicon dioxide nanomaterial, comprising the steps of:

[0045] (1) At room temperature, according to the total surfactant concentration of 0.028mol / L, weigh 0.5715g of cetyltrimethylammonium bromide and 0.1366g of sodium dodecylbenzenesulfonate into 70mL of deionized water, 50Hz Ultrasound at high power for 20 minutes to obtain a clear solution, and then let it stand for 24 hours;

[0046] (2) At room temperature, add 0.8mL of ammonia solution with a mass fraction of 25% to 28% to the clear solution obtained in step (1), then add 10mL of ethanol solution and 20mL of ether solution in turn, stir vigorously for 30min; then quickly add 2.5g tetraethyl orthosilicate solution, vigorously stirred for 4 hours, and a solid precipitate was formed;

[0047] (3) Suction filter the solid precipitate obtained in step (2), wash with water and ethanol three times respectively, and then place it in a drying oven at 60-80° C. for drying for more tha...

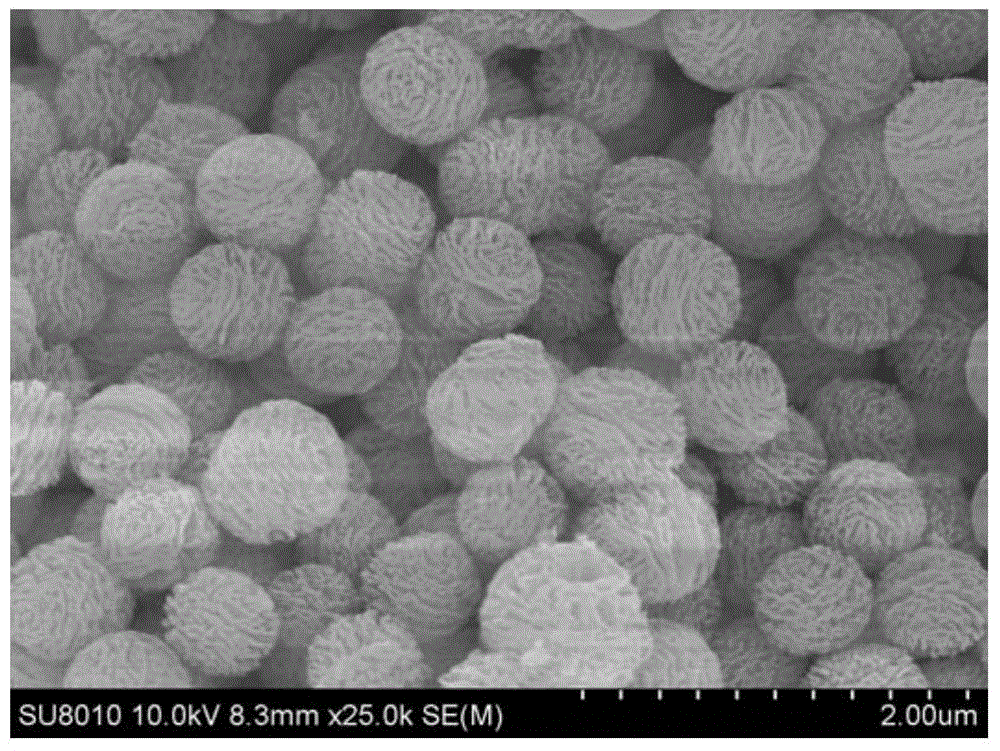

Embodiment 3

[0050] A method for preparing a mesoporous silicon dioxide nanomaterial, comprising the steps of:

[0051] (1) At room temperature, according to the total surfactant concentration of 0.028mol / L, weigh 0.5715g of cetyltrimethylammonium bromide and 0.1366g of sodium dodecylbenzenesulfonate into 70mL of deionized water, 50Hz Ultrasound at high power for 20 minutes to obtain a clear solution, and then let it stand for 24 hours;

[0052] (2) At room temperature, add 0.8mL of ammonia solution with a mass fraction of 25% to 28% to the clear solution obtained in step (1), then add 15mL of ethanol solution and 20mL of ether solution in turn, stir vigorously for 30min; then quickly add 2.5g tetraethyl orthosilicate solution, vigorously stirred for 4 hours, and a solid precipitate was formed;

[0053] (3) Suction filter the solid precipitate obtained in step (2), wash with water and ethanol three times respectively, and then place it in a drying oven at 60-80° C. for drying for more tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com