Preparation method of graphene-carbon nanotube compound film based on three-dimensional network appearance

A technology of carbon nanotube composite and three-dimensional network, which is applied in the field of preparation of graphene-carbon nanotube composite film, to achieve the effect of good uniformity, simple process and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

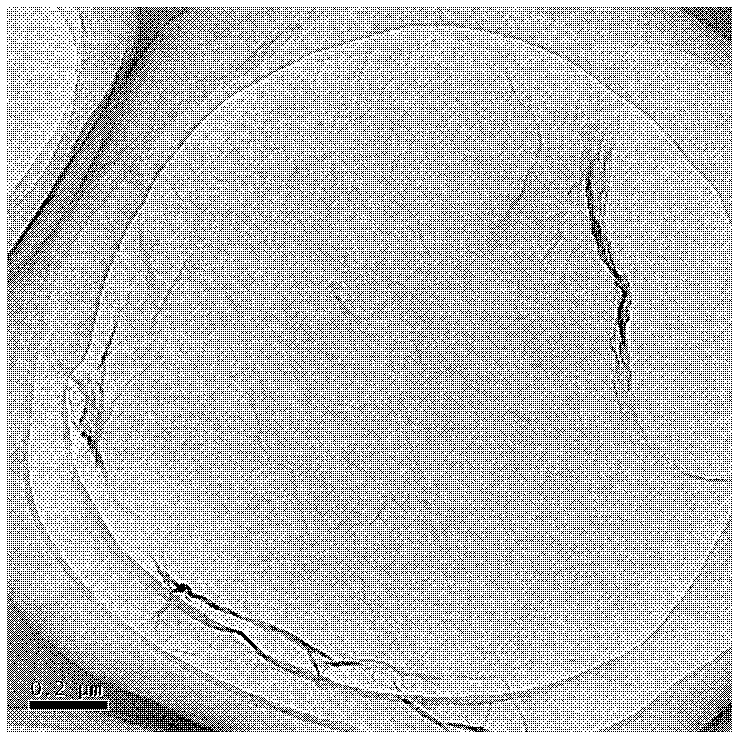

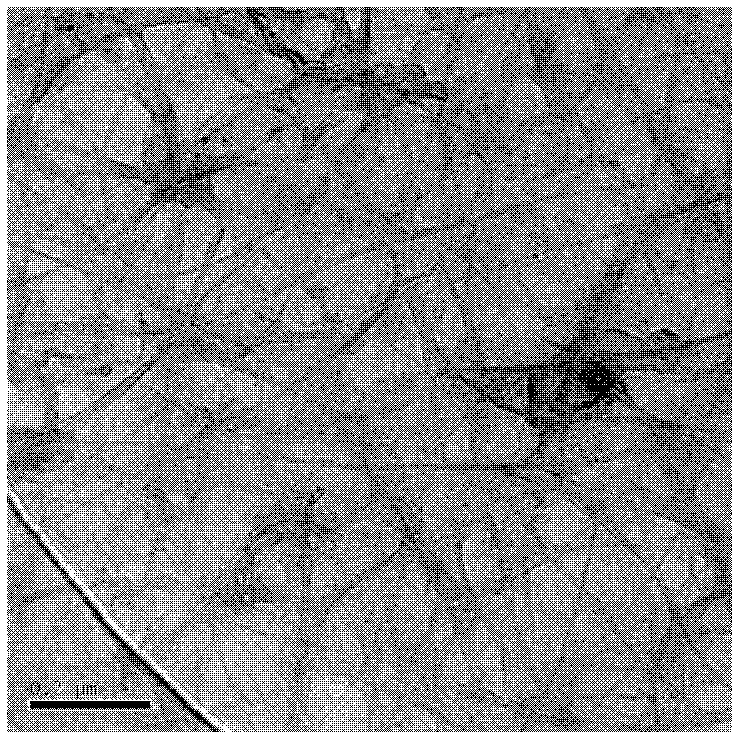

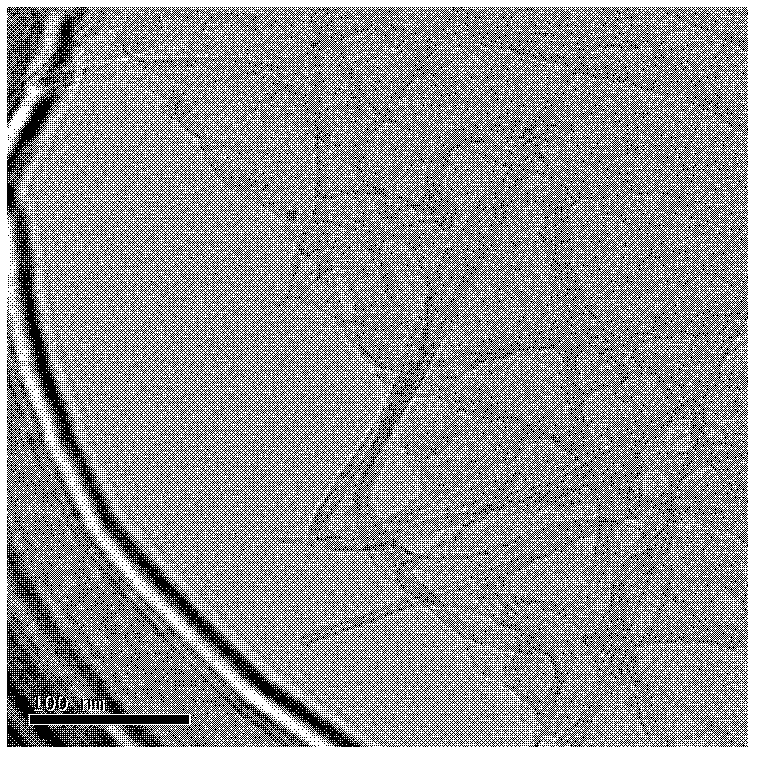

Image

Examples

Embodiment 1

[0047] (1) Using glass as the substrate, the substrate was ultrasonically washed with deionized water and ethanol alternately, and then dried in vacuum for later use.

[0048] (2) Preparation of carbon nanotube solution

[0049] The carbon nanotubes were passed through a vacuum tube furnace at 550 ° C with a volume ratio of air to nitrogen of 1:4 and a total gas flow rate of 300 cm 3 / min mixed gas atmosphere for 1 hour, then condensed and refluxed in a hydrochloric acid solution with a mass concentration of 37% at 100°C for 1 hour, then suction filtered, and repeatedly washed the filter cake with deionized water until the washing liquid was neutral. Vacuum dry at 60°C to obtain pure carbon nanotubes, then add pure carbon nanotubes and surfactant SDS to deionized water, ultrasonically disperse, and prepare carbon nanotubes at a concentration of 0.05 mg / mL, the mass of surfactant The solution whose concentration concentration is 0.5% is recorded as A solution.

[0050] (3) Gr...

Embodiment 2

[0055] In this example, the A solution prepared in step (2) in Example 1 and the B solution prepared in step (3) are mixed evenly according to the mass ratio of graphene oxide and carbon nanotubes in the solution to 1:1. 2:1 mixed evenly, other things are the same, the surface resistance of the obtained graphene-carbon nanotube composite film in the range of transmittance 60~90% is 400~2400 Ω / sq.

Embodiment 3

[0057] In this example, the A solution prepared in step (2) in Example 1 and the B solution prepared in step (3) are mixed evenly according to the mass ratio of graphene oxide and carbon nanotubes in the solution to 1:1. 5:1 mixed evenly, other the same, the obtained graphene-carbon nanotube composite film has a surface resistance of 500~3200 Ω / sq in the range of transmittance 52~85%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface resistance | aaaaa | aaaaa |

| Surface resistance | aaaaa | aaaaa |

| Surface resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com