Polyvinyl dichloride (PVDC) latex used for interior and exterior wall coating materials and preparation method thereof and application thereof

A technology of exterior wall paint and latex, which is applied in the direction of coating, etc., and can solve the problems of waterproof and low moisture resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

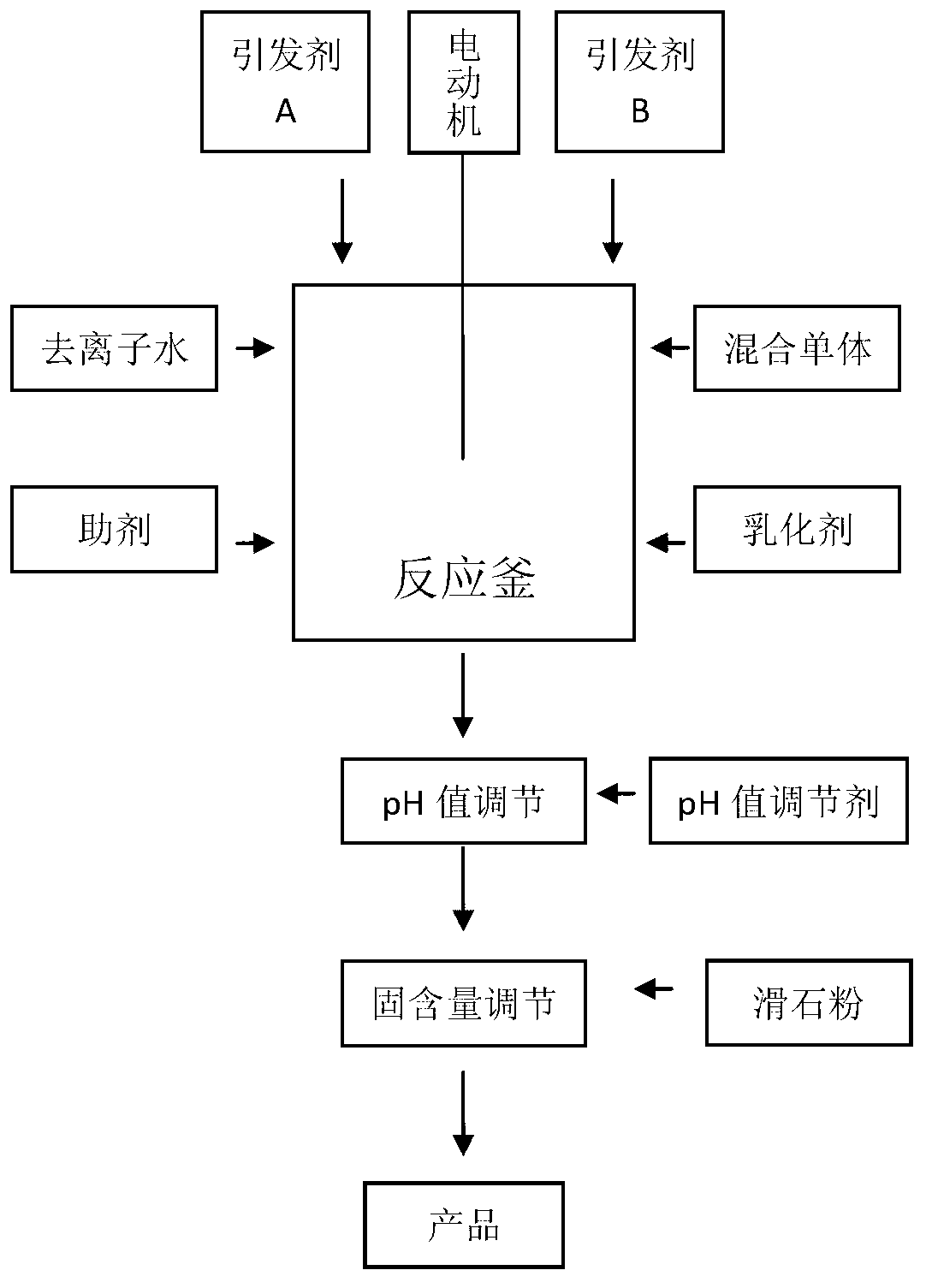

Method used

Image

Examples

Embodiment 1

[0033] For polyvinylidene chloride copolymer latex used in interior and exterior wall coatings, the total weight of the copolymer system is 200kg, and the mixed monomer accounts for 72kg;

[0034] Vinylidene chloride 25.2kg;

[0035] Vinyl chloride 43.2kg;

[0036] Butyl acrylate 3.6kg;

[0037] Auxiliary disodium hydrogen phosphate 16g;

[0038] Initiator: 160g of ammonium persulfate and 160g of sodium bisulfite

[0039] Emulsifier: 1 kg of sodium dodecylbenzene sulfonate and 160 g of OP-10; wherein, sodium dodecylbenzene sulfonate is 400 g of linear sodium dodecylbenzene sulfonate and 600 g of branched chain Sodium dodecyl benzene sulfonate.

[0040] The specific operation process is:

[0041] 1) Preparation of raw materials:

[0042] (1) Preparation of initiator solution: ammonium persulfate 160g and sodium bisulfite 160g are added in deionized water 8kg part and stirred and mixed to make initiator solution;

[0043] (2) Preparation of emulsifier solution: Add 1 kg o...

Embodiment 2

[0054] For polyvinylidene chloride copolymer latex used in interior and exterior wall coatings, the total weight of the copolymer system is 200kg, and the mixed monomer accounts for 72kg;

[0055] Vinylidene chloride 27.36kg;

[0056] Vinyl chloride 43.2kg;

[0057] Butyl acrylate 1.44kg;

[0058] Auxiliary disodium hydrogen phosphate 20g;

[0059] Initiator: 160g of ammonium persulfate and 160g of sodium bisulfite

[0060] Emulsifier: sodium dodecylbenzenesulfonate 1.2kg and 200g of OP-10; wherein, sodium dodecylbenzenesulfonate is linear sodium dodecylbenzenesulfonate with a ratio of 480g and branched sodium dodecylbenzenesulfonate of 720g Sodium dodecylbenzenesulfonate.

[0061] The specific operation process is:

[0062] 1) Preparation of raw materials: The preparation of mixed monomer, emulsifier and initiator is as in Example 1.

[0063] 2) Add bottom water to the reaction kettle, based on the total weight of the copolymerization system of 200kg, add the auxiliary ag...

Embodiment 3

[0066] For polyvinylidene chloride copolymer latex used in interior and exterior wall coatings, the total weight of the copolymer system is 200kg, and the mixed monomer accounts for 72kg;

[0067] Vinylidene chloride 28.8kg;

[0068] Vinyl chloride 39.6kg;

[0069] Butyl acrylate 3.6kg;

[0070] Auxiliary disodium hydrogen phosphate 24g;

[0071] Initiator: 160g of ammonium persulfate and 160g of sodium bisulfite

[0072] Emulsifier: sodium dodecylbenzenesulfonate 1.4kg and 240g of OP-4; wherein, sodium dodecylbenzenesulfonate is straight-chain sodium dodecylbenzenesulfonate and 840g branched Sodium dodecylbenzenesulfonate.

[0073] The specific operation process is:

[0074] 1. Preparation of raw materials: the preparation of mixed monomer, emulsifier and initiator is as in Example 1.

[0075] 2. Put the bottom water into the reaction kettle, based on the total weight of the copolymerization system of 200kg, add the auxiliary agent disodium hydrogen phosphate, emulsifie...

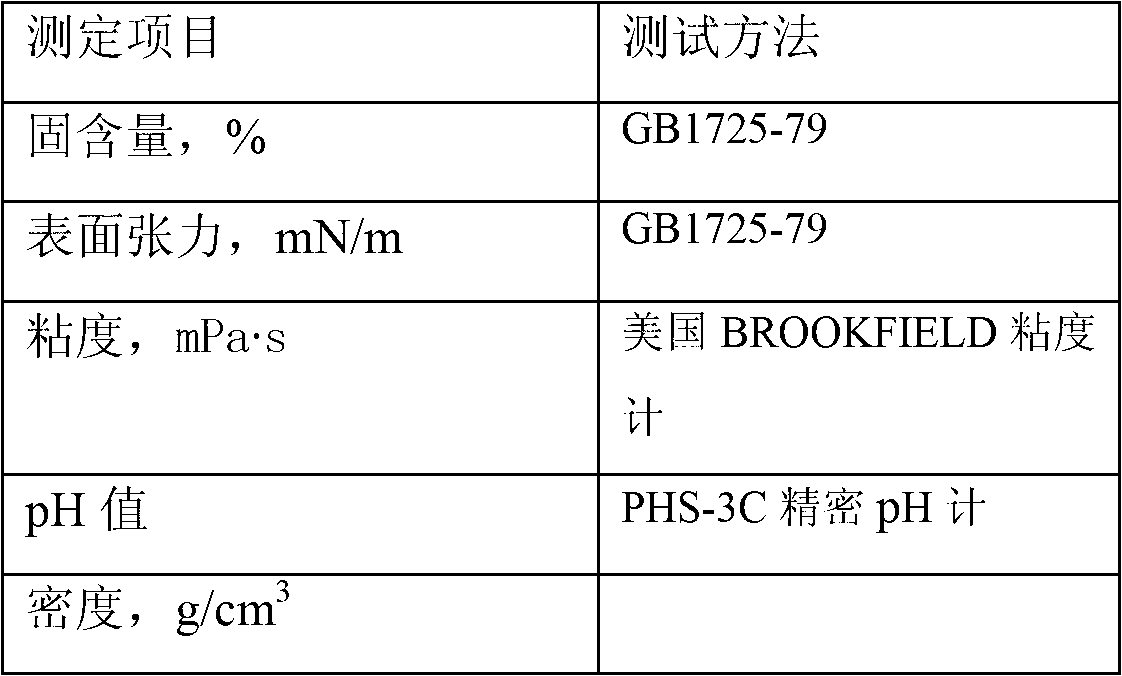

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface tension | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com