Intelligent fire coal scheduling system for thermal power plant

An intelligent dispatching, thermal power plant technology, applied in the direction of comprehensive factory control, electrical program control, comprehensive factory control, etc., can solve the determination of blending ratio and optimization decision-making and management level of combustion, irregular monitoring and management, The problems of increasing pollutant discharge, etc., can ensure the safety and economy, reduce decision-making time, and optimize the effect of blending combustion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following will be described in detail in conjunction with the accompanying drawings and embodiments.

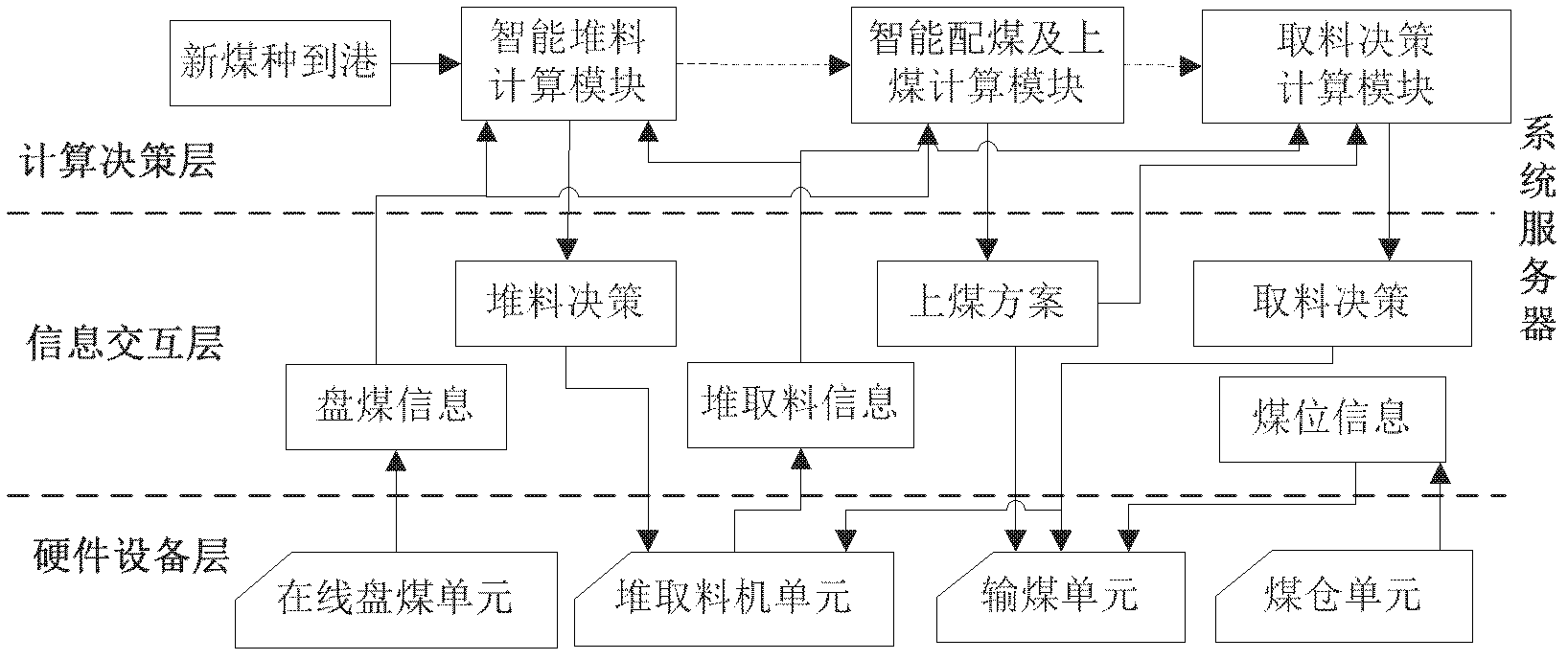

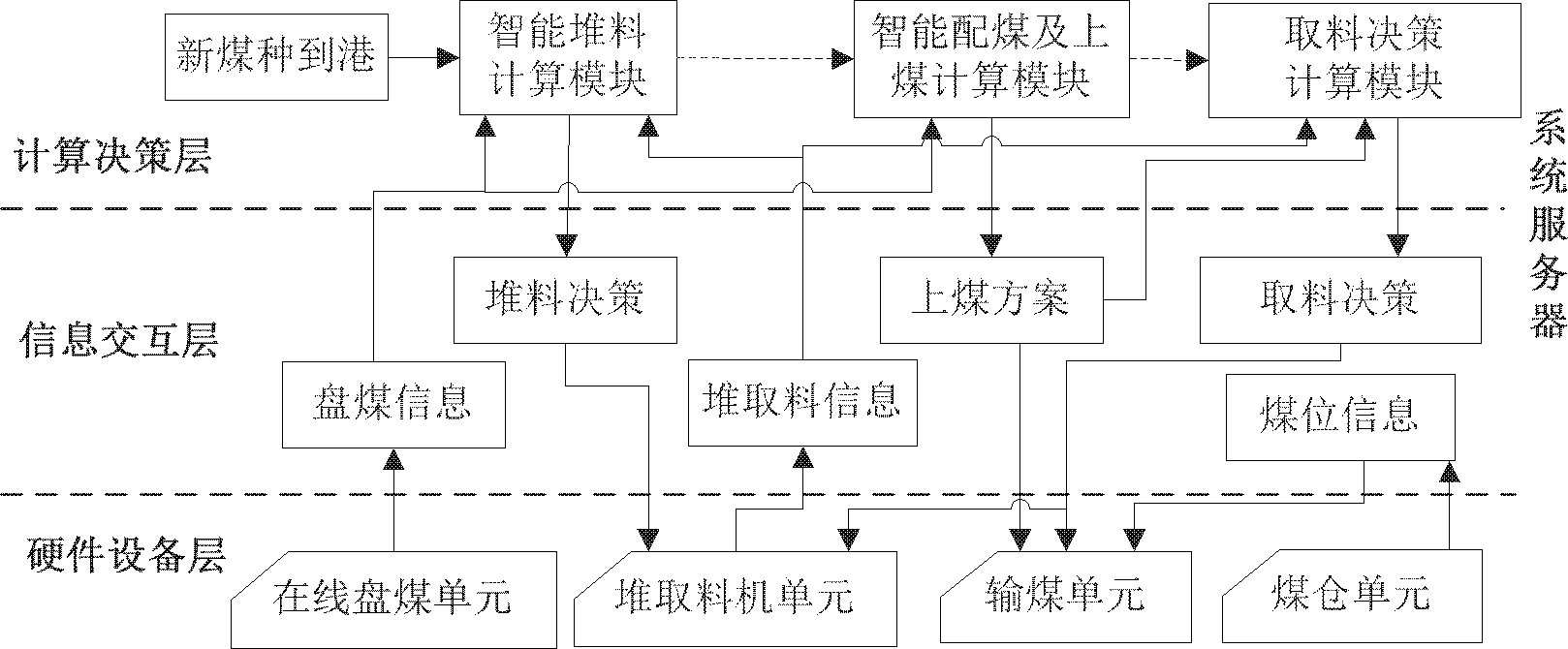

[0030] as attached figure 1 As shown, the system structure is divided into three layers: the lowest layer is the hardware equipment layer, including the existing equipment of the power plant and the equipment and sensors added according to the needs, specifically including the online coal storage unit, the stacker and reclaimer unit, and the coal handling unit and the coal bunker unit; the second layer is the information interaction layer, including the coal pan information transmitted from the coal pan instrument to the server, the stacking and reclaiming information transmitted to the server by the stacker and reclaimer, and the coal level transmitted from the coal bunker unit to the coal handling unit Information and the stacking and reclaiming decisions issued by the server to the stacker-reclaimer, and the coal loading plan and reclaiming decisions sent by the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com